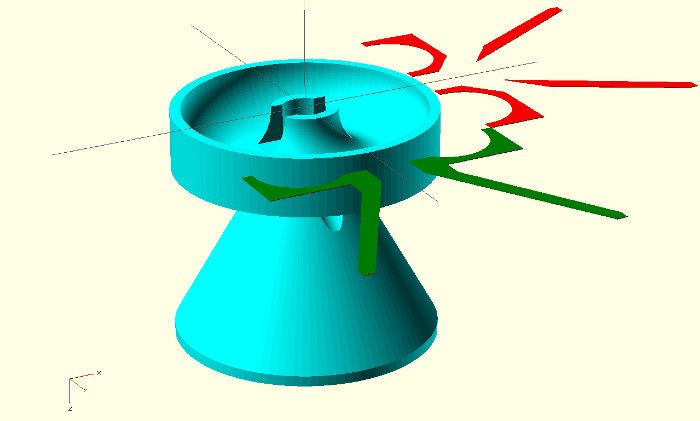

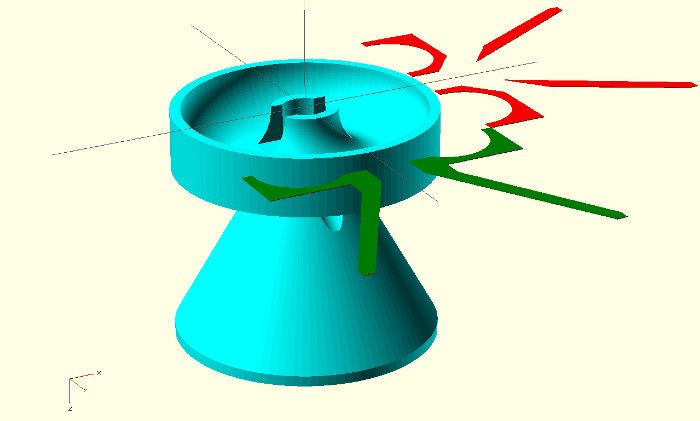

Having seen expensive and complicated suppressor designs sometimes matched by simple and less expensive ones, I thought that maybe it's possible to make a an Economic and Effective Suppressor for myself to be fitted on a rimfire rifle. Any comments are welcome ...

I only have a manual lathe (that I can rig up to do some simple 1 axis milling) so I can't make myself any of the complicated or asymmetric stuff.

I did a bit of brain storming and came up with this hybrid thing that slips over the barrel much like a shroud.

Here's a link to a video showing the cad drawing from various aspects:

https://www.youtube.com/watch?v=hPmtIc5mgxM

And a newer design on same basic concept:

https://www.youtube.com/watch?v=mAHz2tlBbrE

The barrel slips onto the suppressor up to the grooved spacer (that along with the first hybrid baffle performs gas stripping ... more on the design concepts later), so as long as you do the machining right the worst impact on alignment is introduced by the tube not being perfectly straight and cylindrical.

The gases emitted from the muzzle would travel towards the baffle by inertia until they meet with the small tube that would split the flow into a portion that travels in the tube and a portion that keeps on traveling in the main tube until it rebounds of the main body of the baffle and moves back towards the grooved spacer, trough the 4 apertures and back into the cavity between the barrel and the main tube. In an ordinary shroud type suppressor this function would be accomplished by a piece that's generally called “air stripper” and sits at the muzzle just like a compensator would. In the E²S's case this is achieved in such a way that a considerable portion of the initial gas flow gets rebounded back and forth between the baffle and the grooved spacer helping more gas to enter the cavity behind the grooved spacer with the 4 large square holes. Once the pressures in these first two cavities equalizes the flow begins to be primarily directed trough the tube in the baffle so that it is injected into the second cavity between the baffle and the endcap. This second cavity is also constructed so that initially only a small portion of the gases goes trought the second narrow tube and into open space while a large portion of the flow begins a turbulent vortex flow before making it's way out.

Well at least that's the idea ... not sure if it will work like desired.

Well having learned that k baffles tend to work better for low pressure rounds I combined some of the ideas from the E²S and designed a hybrid stripper / k baffle. See post 11 for a link to a video of it viewtopic.php?f=10&t=109033&p=847974#p847974

Here's my bewbi iead for a .22 supressor

Here's my bewbi iead for a .22 supressor

Last edited by louigi600 on Tue Jun 04, 2013 2:35 am, edited 3 times in total.

Re: Here's my bewbi iead for a .22 supressor

If its what you want to do, knock yourself out. I can tell you that it will be heavy, not very effective, and generally a waste of a stamp, but if you want to try it, go for it.

Look at the basic k-baffle designs here. They're going to be your best bet for a simple, effective, and lightweight rimfire suppressor.

Byrdman

Look at the basic k-baffle designs here. They're going to be your best bet for a simple, effective, and lightweight rimfire suppressor.

Byrdman

Re: Here's my bewbi iead for a .22 supressor

Why do you say heavy ? Being for rimfire it's not going to require me to make it out of steel .. or is it ?

Why do you say it's going to knock me out ? The barrel slides on the firs spacer and seals ... only the grooved spacer lets the blast gasses go into the back end like a shroud.

Is some other bad thing going to happen ?

I had a look at the k-baffle design .... but I can't machine that with just my manual lathe ... at least not without having a bad impact on accuracy.

I don't have CNC stuff and I don't have a mill gust a hobby manual lathe and a cheap drill press (without vice).

Why do you say it's going to knock me out ? The barrel slides on the firs spacer and seals ... only the grooved spacer lets the blast gasses go into the back end like a shroud.

Is some other bad thing going to happen ?

I had a look at the k-baffle design .... but I can't machine that with just my manual lathe ... at least not without having a bad impact on accuracy.

I don't have CNC stuff and I don't have a mill gust a hobby manual lathe and a cheap drill press (without vice).

Re: Here's my bewbi iead for a .22 supressor

Check Enfields work on K's these are all manufactured on manual machines, as a matter of fact I think that about 85% or higher here are made on manual machines.louigi600 wrote: I had a look at the k-baffle design .... but I can't machine that with just my manual lathe ... at least not without having a bad impact on accuracy.

I don't have CNC stuff and I don't have a mill gust a hobby manual lathe and a cheap drill press (without vice).

Enfield did some great work and he did have several steps shown in pictures in his treads.

Gunny

- Bendersquint

- Industry Professional

- Posts: 11357

- Joined: Sat Jan 07, 2006 7:19 pm

- Location: North Carolina

- Contact:

Re: Here's my bewbi iead for a .22 supressor

"Knock yourself out" is just a saying, have you never heard it before?louigi600 wrote:Why do you say heavy ? Being for rimfire it's not going to require me to make it out of steel .. or is it ?

Why do you say it's going to knock me out ? The barrel slides on the firs spacer and seals ... only the grooved spacer lets the blast gasses go into the back end like a shroud.

Is some other bad thing going to happen ?

I had a look at the k-baffle design .... but I can't machine that with just my manual lathe ... at least not without having a bad impact on accuracy.

I don't have CNC stuff and I don't have a mill gust a hobby manual lathe and a cheap drill press (without vice).

It is a terrible design for a suppressor as well.

Buy a $50 vise and make K's or use your lathe as a horizontal mill.

Its that easy.

Re: Here's my bewbi iead for a .22 supressor

Sorry I don't live in the States ... and English is not my native language. Sure I've herd it before but not used in a context where you can actually injure yourself. Being new to machining (I've only owned a lathe for 3 months or so) and suppressor smithing I'm actually worried of the consequences of a failure. Ok on a rimfire it's not going to be as bad as a centerfire but till something I'd like to avoid.

As for the design do you say it's terrible because you have tried something like that before ? or because you have software that can do gas flow simulation and have tested it not to be any good ? or just because it looks different and ugly with respect to other designs ? I'm not trying to defend my untested design, it might well be crappy, just want to learn. I'm sure the k-baffle design is the best for lower pressure rounds until someone comes up with a more effective design. I'm not advocating that my design be any better but it's an attempt to make something different from a conventional design.

I've seen a design that is even simple then mine and it was nearly as effective as a SAK. Will a k-baffle design outperform the SAK ? tecnically what's the name of that type of design ?

?

As for the vice I've already tried if I can fit one on my drill press but non seem to fit on my press so I'll need to make an adapter either for the press or for the lathe to rotate 90 the tool tower and put a vice on it then chuck a mill bit.

I might even try fixing the drill press on the same bench over the lathe's tool tower ... but I'm moving house so I'll do that when that's over.

I'll have a crack at making a k-baffle from some scrap to see if I can manage something acceptable.

As for the design do you say it's terrible because you have tried something like that before ? or because you have software that can do gas flow simulation and have tested it not to be any good ? or just because it looks different and ugly with respect to other designs ? I'm not trying to defend my untested design, it might well be crappy, just want to learn. I'm sure the k-baffle design is the best for lower pressure rounds until someone comes up with a more effective design. I'm not advocating that my design be any better but it's an attempt to make something different from a conventional design.

I've seen a design that is even simple then mine and it was nearly as effective as a SAK. Will a k-baffle design outperform the SAK ? tecnically what's the name of that type of design

?

?As for the vice I've already tried if I can fit one on my drill press but non seem to fit on my press so I'll need to make an adapter either for the press or for the lathe to rotate 90 the tool tower and put a vice on it then chuck a mill bit.

I might even try fixing the drill press on the same bench over the lathe's tool tower ... but I'm moving house so I'll do that when that's over.

I'll have a crack at making a k-baffle from some scrap to see if I can manage something acceptable.

I looked up Enfield's posts on this forum but I could only find one. Have you a link to the simplest effective k-baffle design that I can look at ?gunny50 wrote: Check Enfields work on K's these are all manufactured on manual machines, as a matter of fact I think that about 85% or higher here are made on manual machines.

Enfield did some great work and he did have several steps shown in pictures in his treads.

Gunny

- Enfield577

- Silent But Deadly

- Posts: 805

- Joined: Mon Mar 28, 2011 6:29 pm

- Location: New Zealand

Re: Here's my bewbi iead for a .22 supressor

Here is how to make them, you just make smaller ones for a 22

viewtopic.php?f=10&t=81037

Here are some smaller Ks for an integral Ruger MKII

For a 22 can I do 8 ks in a 6" long 1" dia tube with a blast chamber spacer of around 5/8 long

Now you draw something up - can be on paper and show us, we can guide you from there

viewtopic.php?f=10&t=81037

Here are some smaller Ks for an integral Ruger MKII

For a 22 can I do 8 ks in a 6" long 1" dia tube with a blast chamber spacer of around 5/8 long

Now you draw something up - can be on paper and show us, we can guide you from there

Of all the things I've lost it's my mind I miss the most

Re: Here's my bewbi iead for a .22 supressor

Can't see the images on that thread ... but it's probabbly the content filter at work: I'll have a look from home later.Enfield577 wrote:Here is how to make them, you just make smaller ones for a 22

viewtopic.php?f=10&t=81037

Here are some smaller Ks for an integral Ruger MKII

For a 22 can I do 8 ks in a 6" long 1" dia tube with a blast chamber spacer of around 5/8 long

Now you draw something up - can be on paper and show us, we can guide you from there

Thanks for the hint.

Since the pass trough hole on my lathe cannot handle my barrel (I'm limited to about 12mm or 1/2") I'm unable to thread my barrel so I'll need to keep the shroud like slide on thing.

To keep the thing as short as possible can I use the cavity that will be created behind the muzzle as blast chamber with a grooved spacer at the muzzle ? or will that be just wasted space ?

- Enfield577

- Silent But Deadly

- Posts: 805

- Joined: Mon Mar 28, 2011 6:29 pm

- Location: New Zealand

Re: Here's my bewbi iead for a .22 supressor

I think you mean like this ?

That is how I do it

That is how I do it

Of all the things I've lost it's my mind I miss the most

Re: Here's my bewbi iead for a .22 supressor

Thanks !

Yea more or less like that, except my spacer has to sit directly on the barrel that does not eve have a grove.

When I turn it I've to shave about 8/10000" at a time from the center hole, with a tool that looks like an internal threading tool, and check for fit on the barrel. When it slips in and stops on the slightly conic barrel just where I want it I can stop. I've to do this for both the grooved spacer and for the other spacer. I thaught it was time consuming but I guess that making k-baffles will give me another meaning to time consuming.

I managed to pierce the content filter and had a peep at the images. My pass-trough ain't that big I'll have to make a short adapter to turn the face opposite to the cone (the face of the baffle) and probably also something to aid putting it true in my crappy self center chuck.

I've an idea: maybe I can turn the face groove with a custom tool before I cut it off from the rod accepting a little more waste of material ?

Are k-baffles also effective for pcp air rifles ? if I replace my crosman original delring baffles with k-baffles will the pcp become even quieter ?

Yea more or less like that, except my spacer has to sit directly on the barrel that does not eve have a grove.

When I turn it I've to shave about 8/10000" at a time from the center hole, with a tool that looks like an internal threading tool, and check for fit on the barrel. When it slips in and stops on the slightly conic barrel just where I want it I can stop. I've to do this for both the grooved spacer and for the other spacer. I thaught it was time consuming but I guess that making k-baffles will give me another meaning to time consuming.

I managed to pierce the content filter and had a peep at the images. My pass-trough ain't that big I'll have to make a short adapter to turn the face opposite to the cone (the face of the baffle) and probably also something to aid putting it true in my crappy self center chuck.

I've an idea: maybe I can turn the face groove with a custom tool before I cut it off from the rod accepting a little more waste of material ?

Are k-baffles also effective for pcp air rifles ? if I replace my crosman original delring baffles with k-baffles will the pcp become even quieter ?

Re: Here's my bewbi iead for a .22 supressor

Ok I made a cad drawing mixing some ideas from my previous design to a k baffle design. I know that this is not machinable in one piece ... it's to show something.

https://www.youtube.com/watch?v=npSq3lZp_KU

I then thought: what if I try make less turbulence close to the bullet path (attempting to minimize impact on accuracy) and try to generate turbulence closer to the can ?

This is what I came up with:

https://www.youtube.com/watch?v=alzo5sxoaGk

or a symmetric variation of the k baffle:

https://www.youtube.com/watch?v=yMI6VOclJ4M

https://www.youtube.com/watch?v=npSq3lZp_KU

I then thought: what if I try make less turbulence close to the bullet path (attempting to minimize impact on accuracy) and try to generate turbulence closer to the can ?

This is what I came up with:

https://www.youtube.com/watch?v=alzo5sxoaGk

or a symmetric variation of the k baffle:

https://www.youtube.com/watch?v=yMI6VOclJ4M

Re: Here's my bewbi iead for a .22 supressor

Louigi; Making K baffles is really easy, even with a very small lathe. Having a lathe, you are ahead of lots of home

builders. I made my first K's on a Sherline 3inch lathe, attached the tube to the barrel with setscrews, because the Sherline didn't thread. Since that time, I've bought a larger lathe and a milling machine that will soon be computer controlled (mill, not lathe) But that small lathe and mill still get some use for really small model engine parts.

builders. I made my first K's on a Sherline 3inch lathe, attached the tube to the barrel with setscrews, because the Sherline didn't thread. Since that time, I've bought a larger lathe and a milling machine that will soon be computer controlled (mill, not lathe) But that small lathe and mill still get some use for really small model engine parts.

Re: Here's my bewbi iead for a .22 supressor

Yeah I know ... my HobbyMat chucks a maximum diameter of about 80mm, has a 1/2" pass-trough hole and when I got it second had it was missing gears for threading.

I now have the gears but I need to machine them and have the bore notched to be able to make threads. But I'm not complaining ... much better then a hand drill fixed to a bench and grinding material off with a dremmel

I now have the gears but I need to machine them and have the bore notched to be able to make threads. But I'm not complaining ... much better then a hand drill fixed to a bench and grinding material off with a dremmel

Re: Here's my bewbi iead for a .22 supressor

Well, that sounds like some work ahead. I use 28 threads per inch (tpi) for most everything. I do use

32 and 36 tpi when the material is very thin, or to match barrel threading. For 30 cal. (7.62mm) most

here are 24 tpi. So you don't really need a lot more for suppressor making. I may be wrong, but I'm thinking

AK's are 1mm pitch and Left Hand threads.

Hope this is useful, and if you have questions on gearing, might be able to help there too.

Good Luck and have Fun.

32 and 36 tpi when the material is very thin, or to match barrel threading. For 30 cal. (7.62mm) most

here are 24 tpi. So you don't really need a lot more for suppressor making. I may be wrong, but I'm thinking

AK's are 1mm pitch and Left Hand threads.

Hope this is useful, and if you have questions on gearing, might be able to help there too.

Good Luck and have Fun.

Re: Here's my bewbi iead for a .22 supressor

That's very useful information, I'll keep that in mind just in case one day I need to make a can for someone else, but for now they're just for personal use, and not being able to thread the barrel it's not an issue for the minute. When I'll have the gears ready I can try threading airgun barrels because some of them are 11mm.

Left-handed threads are not in the capabilities of my lathe, well not until I find a way of removing or adding a gear coupling to reverse just the rotation of the advancement screw. But that's even more work ahead

Left-handed threads are not in the capabilities of my lathe, well not until I find a way of removing or adding a gear coupling to reverse just the rotation of the advancement screw. But that's even more work ahead

Re: Here's my bewbi iead for a .22 supressor

stop playing around with complicated "designs". go simple or go home. seriously try a simple k baffle you wont be sorry.

listen to enfield, he has been taught well.

listen to enfield, he has been taught well.

NP

Re: Here's my bewbi iead for a .22 supressor

I am going about making K's but none the less I still like to talk about my ideas and possible ways to work around the limitations I have on my lathe.

I'm really new to lathe work so it will be a while before I produce something that has a finish that I can show. Put it this way: I'm practicing

What sort of pressure would I be getting out of a subsonic .22 LR round at the muzzle of a 16" barrel ?

Would the can need to be made of something that is graded to that sort of pressure ?

If I were to make it out of aluminum pipe how thick should the walls be ? or is is a no go and steel can is mandatory even for 22LR ?

Enfield's can above looks like it's aluminum but I may be wrong. If it's steel I'm surprised for the thickness

How thick should the baffle walls be ? Are they aluminum too ?

I made my test split collets from recycled HDPE (from molten bottle lids) and they're looking good enough for me to try make them from aluminum.

The HDPE took up the slack in the conicity of the barrel ... but I'm now suspecting that the same will not happen if I make them from aluminum, I'll probably ha veto give them a tad of conicity too.

I'm really new to lathe work so it will be a while before I produce something that has a finish that I can show. Put it this way: I'm practicing

What sort of pressure would I be getting out of a subsonic .22 LR round at the muzzle of a 16" barrel ?

Would the can need to be made of something that is graded to that sort of pressure ?

If I were to make it out of aluminum pipe how thick should the walls be ? or is is a no go and steel can is mandatory even for 22LR ?

Enfield's can above looks like it's aluminum but I may be wrong. If it's steel I'm surprised for the thickness

How thick should the baffle walls be ? Are they aluminum too ?

I made my test split collets from recycled HDPE (from molten bottle lids) and they're looking good enough for me to try make them from aluminum.

The HDPE took up the slack in the conicity of the barrel ... but I'm now suspecting that the same will not happen if I make them from aluminum, I'll probably ha veto give them a tad of conicity too.

- Enfield577

- Silent But Deadly

- Posts: 805

- Joined: Mon Mar 28, 2011 6:29 pm

- Location: New Zealand

Re: Here's my bewbi iead for a .22 supressor

For a 22 you can make it all out of commercial Al. no problem

I did a test on here a while back, machining a can thinner and thinner, it was a 22 can and got down to about 0.1mm thick before it burst

I did a test on here a while back, machining a can thinner and thinner, it was a 22 can and got down to about 0.1mm thick before it burst

Of all the things I've lost it's my mind I miss the most

Re: Here's my bewbi iead for a .22 supressor

I made a .22 rimmy sub silencer using pvc waste pipe for the tube and delrin (plastic) for the core . several years later and hundreds of shots and its still working fine

Re: Here's my bewbi iead for a .22 supressor

So if I'm tempted to try my test unit made from electrical conduit PVC pipe (1.5 mm wall thickness) and internals made from recycled HDPE and Al tubing inserts for the bullet I'll be OK ?

Re: Here's my bewbi iead for a .22 supressor

Bless our British Cousins and their innovativeness.nutshot wrote:I made a .22 rimmy sub silencer using pvc waste pipe for the tube and delrin (plastic) for the core . several years later and hundreds of shots and its still working fine

The same creative lineage that gave us

the Luftwaffe defeating Mitchell Supermarine SpitFire; Bletchley

Park Hut 6 Enigma Code breakers; Radar; SOE ( "Between Silk & Cyanide" - Leo Marks )

and at their zenith -the Aston Martin Vantage.

Class will always out.

Best.

Re: Here's my bewbi iead for a .22 supressor

Historian wrote:Bless our British Cousins and their innovativeness.nutshot wrote:I made a .22 rimmy sub silencer using pvc waste pipe for the tube and delrin (plastic) for the core . several years later and hundreds of shots and its still working fine

The same creative lineage that gave us

the Luftwaffe defeating Mitchell Supermarine SpitFire; Bletchley

Park Hut 6 Enigma Code breakers; Radar; SOE ( "Between Silk & Cyanide" - Leo Marks )

and at their zenith -the Aston Martin Vantage.

Class will always out.

Best.

Don`t forget the Morgan Historian , The car made from wood in some blokes shed