I know this is not a silencer question, but this is where the machinist's hang out on this forum.

My employer is trying to find suggestions for a precision, heavy duty manual lathe to replace the Moriseiki I am currently running. His opinion is that everyone is focused on CNC right now, and there are not many bullet proof manual lathes being built.

We are wanting something with around a 3" spindle bore and ball park of a 60" bed. Of course quick change gear box,threading, steady rest, following rest and all the other bells and whistles are desired including DRO.....preferably 3 axis (bed, crossfeed, and compound)....don't really care about tapering ability.

The last one he looked at was a Willis. I was not along for the ride, so I don't know what they didn't like about it, but they weren't impressed. My understanding was the one we were considering was about $30K. His main interest is finding something we can run every day, 8-10 hours a day, that will be reliable and accurate, and will last 15+ years if it is taken care of. He want's this to be a long term solution or he doesn't want to pull the trigger.

Any suggestions?

The stuff I am doing is not ultra precise.....the tightest tolerance window I remember is about a .0007" range, but plus or minus .001" is fairly common on the parts I make.

Any suggestions for a new precision, heavy duty manual lathe

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Any suggestions for a new precision, heavy duty manual lathe

The myopic majority will be our republic's undoing.

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Any suggestions for a new precision, heavy duty manual l

The Mori Seiki is my idea of a dream machine.

A Clausing Colchester I think he would be very happy with me too.Tarnow makes a heck of a machine.Haas comes to mind many others.

Must features

D style chuck

a taper attachment

A heavy tail-stock MT-5+

Variable speed control very slow to over 20-2,000 rpm +++.

A fully bathed gear box ie:engine lathe.

2-4 tpi to whatever.A universal threading box is best.

Apron drive rod must be separate from threading rod.

Meehanite casting

Meehanite casting

MT or BS spindle taper.

All the accessories 3,4,6,w/ buck adjust, face plate,steady,follow rest live and dead centers (Royal)with Albrecht-drill-chucks

A quick change plus a lantern style tool post.

A 16-24" model will have what you need most of the time

The shop will need a overhead rail for changing chucks

A Clausing Colchester I think he would be very happy with me too.Tarnow makes a heck of a machine.Haas comes to mind many others.

Must features

D style chuck

a taper attachment

A heavy tail-stock MT-5+

Variable speed control very slow to over 20-2,000 rpm +++.

A fully bathed gear box ie:engine lathe.

2-4 tpi to whatever.A universal threading box is best.

Apron drive rod must be separate from threading rod.

MT or BS spindle taper.

All the accessories 3,4,6,w/ buck adjust, face plate,steady,follow rest live and dead centers (Royal)with Albrecht-drill-chucks

A quick change plus a lantern style tool post.

A 16-24" model will have what you need most of the time

The shop will need a overhead rail for changing chucks

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

Re: Any suggestions for a new precision, heavy duty manual l

Capt. , we tool junkies love it when you talk dirty like this!Capt. Link. wrote:The Mori Seiki is my idea of a dream machine.

A Clausing Colchester I think he would be very happy with me too.Tarnow makes a heck of a machine.Haas comes to mind many others.

Must features

D style chuck

a taper attachment

A heavy tail-stock MT-5+

Variable speed control very slow to over 20-2,000 rpm +++.

A fully bathed gear box ie:engine lathe.

2-4 tpi to whatever.A universal threading box is best.

Apron drive rod must be separate from threading rod.

Meehanite casting

MT or BS spindle taper.

All the accessories 3,4,6,w/ buck adjust, face plate,steady,follow rest live and dead centers (Royal)with Albrecht-drill-chucks

A quick change plus a lantern style tool post.

A 16-24" model will have what you need most of the time

The shop will need a overhead rail for changing chucks

Excellent characteristics that mere mortals can only dream about.

Look out if there is a win in the next Power Ball.

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

I love the lathe I am using, and I wish they would just get it rebuilt. It fills the bill jut fine accept for what doesn't work, and the spindle bore only being a little over 2". The threading drive to the apron is not working, and the brake is shot, and the zero adjust chuck could stand to be replaced, as well as it doesn't have a DRO. The fellow I replaced was an old timer that didn't want a DRO, so they never put one on it.

When I started they said they were willing to put a DRO on it, but with the other issues the lathe had, and the parts all having to be custom built to fix it, they were more interested in a new one then putting a DRO on this one. We make custom parts for the machines we build every day, so I am still scratching my head as to why we don't just make the parts, but I don't run the show.

We have an over-head hoist to change chucks, and chuck up heavy parts.

....I hope I get a chance to buy it, if they replace it.....I'll figure out how to make the threading drive gear.

When I started they said they were willing to put a DRO on it, but with the other issues the lathe had, and the parts all having to be custom built to fix it, they were more interested in a new one then putting a DRO on this one. We make custom parts for the machines we build every day, so I am still scratching my head as to why we don't just make the parts, but I don't run the show.

We have an over-head hoist to change chucks, and chuck up heavy parts.

....I hope I get a chance to buy it, if they replace it.....I'll figure out how to make the threading drive gear.

The myopic majority will be our republic's undoing.

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Any suggestions for a new precision, heavy duty manual l

Most of the parts you need should be available.The threading dials gear may be disengaged and not broken check it next time you clean and lube.There may be a manual take it home and study it and check the machine point by point to find all the gremlins not just the ones you know about.If you can afford what you can't repair yourself let him know of your desire to buy it.Many times its a win win for both party's.

You know that I will help you find parts or locate a rebuild shop teach you on how to pour Babbitt etc and I think that every one would like to hear what it takes to rebuild a world class machine.

-------------------------------------------------------------------------------------

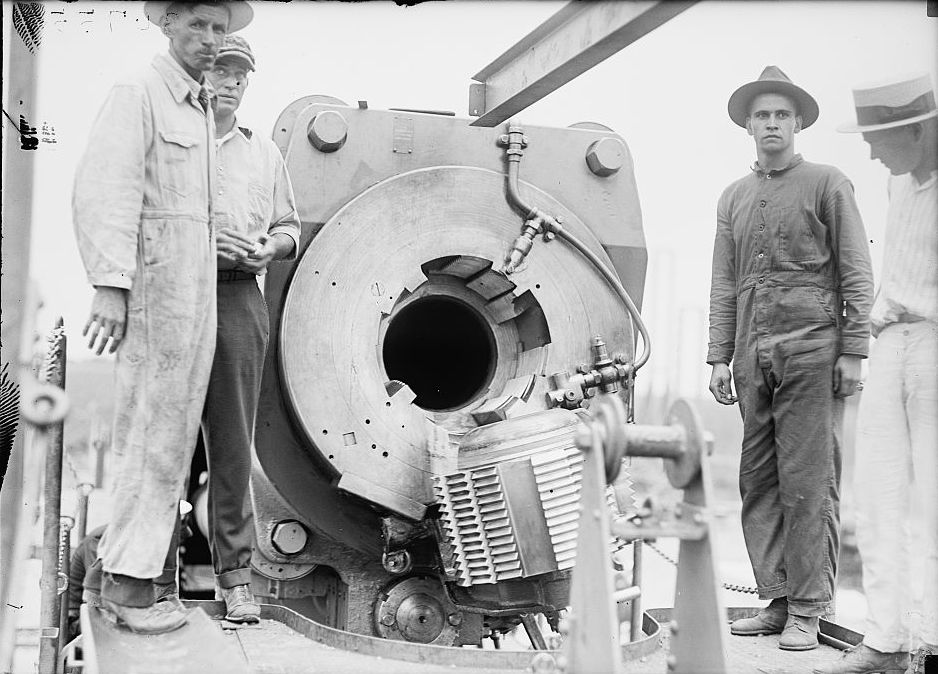

I've been busting at the seams and still tired from all the work involved getting it home.I acquired a new machine and wish to share this find.While this one is in near pristine condition it could be rebuilt by a amateur with skill and perseverance.

This is about chest high and is in the 1500lb class.

The motor alone is a classic with oil cups on the bearing ends.

http://www.ellingsenresearch.com/ebay/whipp1g.jpg

http://www.ellingsenresearch.com/ebay/whipp1f.jpg

http://www.ellingsenresearch.com/ebay/whipp1e.jpg

http://www.ellingsenresearch.com/ebay/whipp1d.jpg

http://www.ellingsenresearch.com/ebay/whipp1c.jpg

http://www.ellingsenresearch.com/ebay/whipp1b.jpg

http://www.ellingsenresearch.com/ebay/whipp1a.jpg

You know that I will help you find parts or locate a rebuild shop teach you on how to pour Babbitt etc and I think that every one would like to hear what it takes to rebuild a world class machine.

-------------------------------------------------------------------------------------

I've been busting at the seams and still tired from all the work involved getting it home.I acquired a new machine and wish to share this find.While this one is in near pristine condition it could be rebuilt by a amateur with skill and perseverance.

This is about chest high and is in the 1500lb class.

The motor alone is a classic with oil cups on the bearing ends.

http://www.ellingsenresearch.com/ebay/whipp1g.jpg

http://www.ellingsenresearch.com/ebay/whipp1f.jpg

http://www.ellingsenresearch.com/ebay/whipp1e.jpg

http://www.ellingsenresearch.com/ebay/whipp1d.jpg

http://www.ellingsenresearch.com/ebay/whipp1c.jpg

http://www.ellingsenresearch.com/ebay/whipp1b.jpg

http://www.ellingsenresearch.com/ebay/whipp1a.jpg

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

I have not dug into the machine very far, I was told the gear that drives the PTO to the apron is broken...anyway the shaft that drives the threading doesn't turn.

I don't know if I could afford it, but I will try if I get the chance.

It is good to know I would have help if I got it....but I figured that was the case.

Capt. your picture links aren't working....and I want to see your new baby.

I don't know if I could afford it, but I will try if I get the chance.

It is good to know I would have help if I got it....but I figured that was the case.

Capt. your picture links aren't working....and I want to see your new baby.

The myopic majority will be our republic's undoing.

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Any suggestions for a new precision, heavy duty manual l

This dates from the late 1920-1930s and has seen very low use.The condition is amazing and the tooling was present as well.

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

Re: Any suggestions for a new precision, heavy duty manual l

Nice shaper! I've got some time there. What are you planning there?

As far as the lathe for DC, 30 k may not get what you need. I'm at 25k now for my new toy and base price was 15k. Still no tools or dro but everything else.

As far as the lathe for DC, 30 k may not get what you need. I'm at 25k now for my new toy and base price was 15k. Still no tools or dro but everything else.

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Any suggestions for a new precision, heavy duty manual l

I'm not telling what you have but am looking forward to pictures.For me this was the last cog for building rifles from bar stock,bolt to falling block even the Welin stepped interrupted screw breech.Ever wonder how they made these! I have a piece of steel just for that.SRM wrote:Nice shaper! I've got some time there. What are you planning there?

As far as the lathe for DC, 30 k may not get what you need. I'm at 25k now for my new toy and base price was 15k. Still no tools or dro but everything else.

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

That is a chunk of iron! I have never been around a shaper in use. I will have to look for a Youtube video or something.

My employer has been upgrading equipment all over the shop. He has bought 2 of the gigantic Viper CNC bridge mills in the last 6 months or so. $30K was the price tag on the Willis lathe he looked at, but I don't think it is necessarily the limit. He just doesn't want to have to shop for another manual lathe for a very long time if he buys one.

My employer has been upgrading equipment all over the shop. He has bought 2 of the gigantic Viper CNC bridge mills in the last 6 months or so. $30K was the price tag on the Willis lathe he looked at, but I don't think it is necessarily the limit. He just doesn't want to have to shop for another manual lathe for a very long time if he buys one.

The myopic majority will be our republic's undoing.

Re: Any suggestions for a new precision, heavy duty manual l

For a nice manual lathe, I've always loved the Monarch 10EE, the Hardinge HLV, and Clausing is another good brand. IIRC, the HLV is still being made.

If you can find an old Pratt & Whitney lathe, these things are just an awesome chunk of good old American Iron. P&W lathes used to be placed on U.S. Navy vessels. I've seen one restored, and it was magnificent!

If you can find an old Pratt & Whitney lathe, these things are just an awesome chunk of good old American Iron. P&W lathes used to be placed on U.S. Navy vessels. I've seen one restored, and it was magnificent!

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

Baffled....I don't think he is really looking for a used one, unless it was a "like-new" bargain or something, I will take a look at the Hardinge. The Clausing looks like and option, and the Haas toolroom lathes might be an option he would consider, since there are days they would like give me some parts with a higher number of multiples.....being a manual with CNC capabilities might be appealing.

Not finding any straight manual options in the Haas, but I may just be looking in the wrong place.

Not finding any straight manual options in the Haas, but I may just be looking in the wrong place.

The myopic majority will be our republic's undoing.

Re: Any suggestions for a new precision, heavy duty manual l

FWIW, the moniker "tool room lathe" has good implications for the home shop guy, vs "engine lathe."

The former are used in labs and R & D shops for prototyping and critical one-off type of work. If they actually follow the design criteria for what a tool room lathe is supposed to be, it'll be extremely accurate, rigid, heavy duty, with excellent headstock bearings, and typically a wide range of feed and speed.

The HLV series is interesting. The feed (when not threading) is done with an independant DC motor that drives clutches for both carriage and cross. The system can be slowed down to a barely perceptible crawl, and is completely independent of the spindle. In a nutshell, it is sweet. Ditto on the threading system, which has a special clutch to kick off the half nuts. I can cut a thread relief in a giant bull barrel only 0.030" wide, and with the threading tool screaming up to a massive shoulder, it'll de-couple right in the middle of that relief groove. Another nice feature.

I've never worked on a Monarch 10EE, but it's supposedly better than the HLV series.

My point is, if a guy is lathe shopping, it's hard to go wrong with a lathe labeled tool room. Engine lathes are what we are used, to, good, solid machines, but generally not as tight.

CNC - how many guys join ST and are intimidated by manual machining, and immediately can think of nothing but CNC? They are incredibly capable, but for so much work, when we are not turning 100+ off, a manual machine is faster and easier.

I'm just tossing this out as a kind of stream of consciousness thing. I made the mistake of buying the wrong lathe as a noob, and losing thousands of dollars getting rid of it, and finding what I really wanted.

The former are used in labs and R & D shops for prototyping and critical one-off type of work. If they actually follow the design criteria for what a tool room lathe is supposed to be, it'll be extremely accurate, rigid, heavy duty, with excellent headstock bearings, and typically a wide range of feed and speed.

The HLV series is interesting. The feed (when not threading) is done with an independant DC motor that drives clutches for both carriage and cross. The system can be slowed down to a barely perceptible crawl, and is completely independent of the spindle. In a nutshell, it is sweet. Ditto on the threading system, which has a special clutch to kick off the half nuts. I can cut a thread relief in a giant bull barrel only 0.030" wide, and with the threading tool screaming up to a massive shoulder, it'll de-couple right in the middle of that relief groove. Another nice feature.

I've never worked on a Monarch 10EE, but it's supposedly better than the HLV series.

My point is, if a guy is lathe shopping, it's hard to go wrong with a lathe labeled tool room. Engine lathes are what we are used, to, good, solid machines, but generally not as tight.

CNC - how many guys join ST and are intimidated by manual machining, and immediately can think of nothing but CNC? They are incredibly capable, but for so much work, when we are not turning 100+ off, a manual machine is faster and easier.

I'm just tossing this out as a kind of stream of consciousness thing. I made the mistake of buying the wrong lathe as a noob, and losing thousands of dollars getting rid of it, and finding what I really wanted.

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

Baffled.....in case you missed it, I am kicking around looking for good options to replace the lathe I run at my day job. My employer was saying there aren't many companies building high quality manual lathes, and he was looking for a good replacement for the Mori Seiki MS-850 I run.

Looked at Hardinge's website and they only list CNC lathes....have they licenced the name to another manufacture?

The Haas toolroom/CNC lathe seems like a good option as long as it is easy to use as a manual lathe. The parts I make are normally lots of 1-6, but every now and then 12-20 or more. It would expand the capabilities of my work station and make it possible to run larger lots of parts.

Looked at Hardinge's website and they only list CNC lathes....have they licenced the name to another manufacture?

The Haas toolroom/CNC lathe seems like a good option as long as it is easy to use as a manual lathe. The parts I make are normally lots of 1-6, but every now and then 12-20 or more. It would expand the capabilities of my work station and make it possible to run larger lots of parts.

The myopic majority will be our republic's undoing.

Re: Any suggestions for a new precision, heavy duty manual l

I'd go with the Haas Toolroom Lathes then.

I don't personally run one, but have been playing around with one some time ago. Some may say they aren't as rigid as a good sturdy Ground Bedway type Lathe, but I say f*ck it. Run modern Tooling, higher RPM and faster Feed Rates rather than High DOC, low RPM and low Feed Rates.

From what I understand it's no Problem "teaching" the Part on the TL and running it over and over again. This will surely boost Productivity. Just be sure to get a good Quick Change Tool Post.

I don't personally run one, but have been playing around with one some time ago. Some may say they aren't as rigid as a good sturdy Ground Bedway type Lathe, but I say f*ck it. Run modern Tooling, higher RPM and faster Feed Rates rather than High DOC, low RPM and low Feed Rates.

From what I understand it's no Problem "teaching" the Part on the TL and running it over and over again. This will surely boost Productivity. Just be sure to get a good Quick Change Tool Post.

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

I am going to throw that idea out there and see what he thinks, I also found a MoriSeiki MS-850 just like the one I have been running. They say it has been sitting unplugged for 20 years and has very little wear, and everything works. The only problem with it is that it would of course be the same size spindle bore too, and we were hoping to get something with a 3" bore or bigger.....but there would be zero learning curve on it, other then getting used to threading on it. That should come pretty quick since I am so familiar with the machine.

If you have had the opportunity the run one of the Haas toolroom lathes, did it have the RPM compensation so that it increases rpm as it gets closer to the center to maintain a consistent finish on the face?

If you have had the opportunity the run one of the Haas toolroom lathes, did it have the RPM compensation so that it increases rpm as it gets closer to the center to maintain a consistent finish on the face?

The myopic majority will be our republic's undoing.

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Any suggestions for a new precision, heavy duty manual l

Do you know why the Willis machine was rejected?

I like Clausing because of parts being available and the Colchester is the right size for my needs but it will depend on what's around when I'm ready to trade up.

I like Clausing because of parts being available and the Colchester is the right size for my needs but it will depend on what's around when I'm ready to trade up.

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

Re: Any suggestions for a new precision, heavy duty manual l

AFAIK all TL's have Constant Surface Speed Option, at least in Program Mode. But couldn't be a Fault to ask your nearest Haas Factory Outlet.daviscustom wrote:If you have had the opportunity the run one of the Haas toolroom lathes, did it have the RPM compensation so that it increases rpm as it gets closer to the center to maintain a consistent finish on the face?

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Any suggestions for a new precision, heavy duty manual l

I don't really know why they passed on the Willis, I think it was mostly because the salesman took a guy that runs a precision machine manufacture to a truck machine shop to look at a lathe in operation.....and the machine was only used to build drive shafts, had never been out of the gear it was in, and was not very well maintained. They were hoping to get info on accuracy, reliability, and so on, and the guys at this shop knew nothing. That let a bad taste in their mouth and they were not impressed.

My guess is there is nothing wrong with the Willis lathe....they just haven't found anyone to get solid info from.

My guess is there is nothing wrong with the Willis lathe....they just haven't found anyone to get solid info from.

The myopic majority will be our republic's undoing.

Re: Any suggestions for a new precision, heavy duty manual l

Hi to all here I have been looking at this forum for a while now and thought that I might as well join up.I have a 15x50 Colchester lathe and I love it. MSC sells them and I think you can get a 3'' spindle bore. Sharp Machine Tools makes a very good lathe and you can get it in a 3" bore also, they are made in Tiwan but are very high quality tools.