I've had an old Smithy AT-300 Lathe/Mill/Drill for about 5 years and have pretty much worn it out using it for things bigger than its designed for. I've used it to build just about everything including form 1 suppressor builds, chambering and barreling rifles from .223 up to 300 win mag, and fabricating parts to adapt car engines to marine use. The spindle bore is only 1.1 in and its slowest spindle speed is 150rpm which made threading to a shoulder a slow affair turning the spindle by hand.

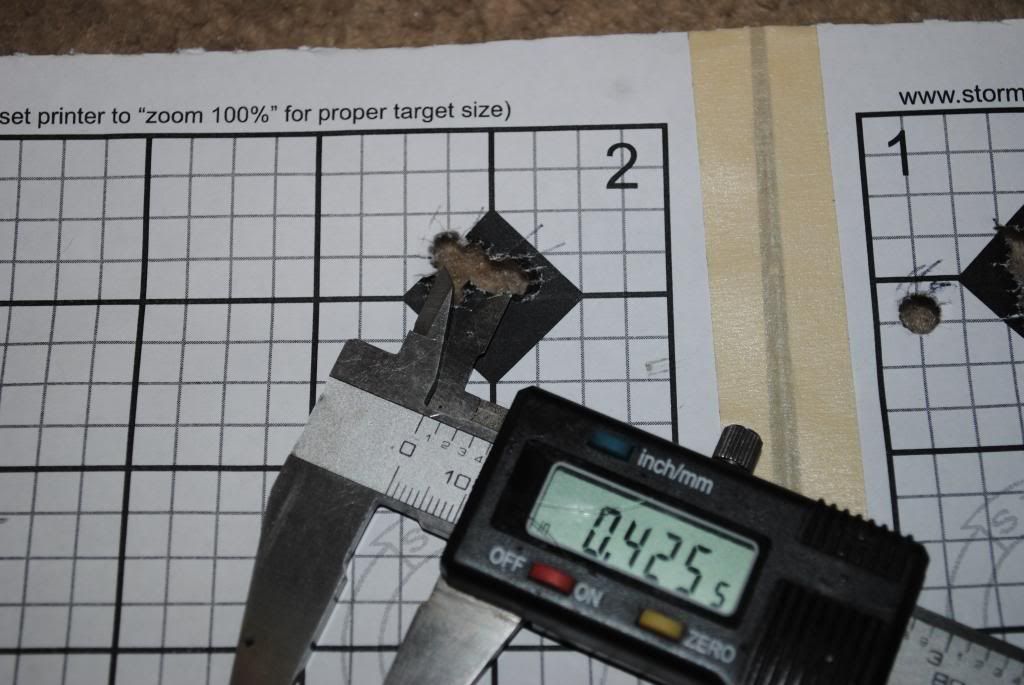

I've become pretty good at finding ways to get past its limitations, like turning the chamber end concentric on a center, putting the slimmer end of a barrel through the 4 jaw and into the spindle bore, indicating the muzzle end of the bore with a range rod on the backside and supporting the chamber end in a steady rest to thread and chamber. The bearings have worn and now have about .001 of play and it will cost more time and money than its worth to rebuild the headstock. I decided to upgrade to a bigger lathe and convert the AT-300 into a light duty mill.

Smithy has been good to me over the years with regard to parts and help so im sticking with them, even though I'm paying a little more than I would through Grizzly.

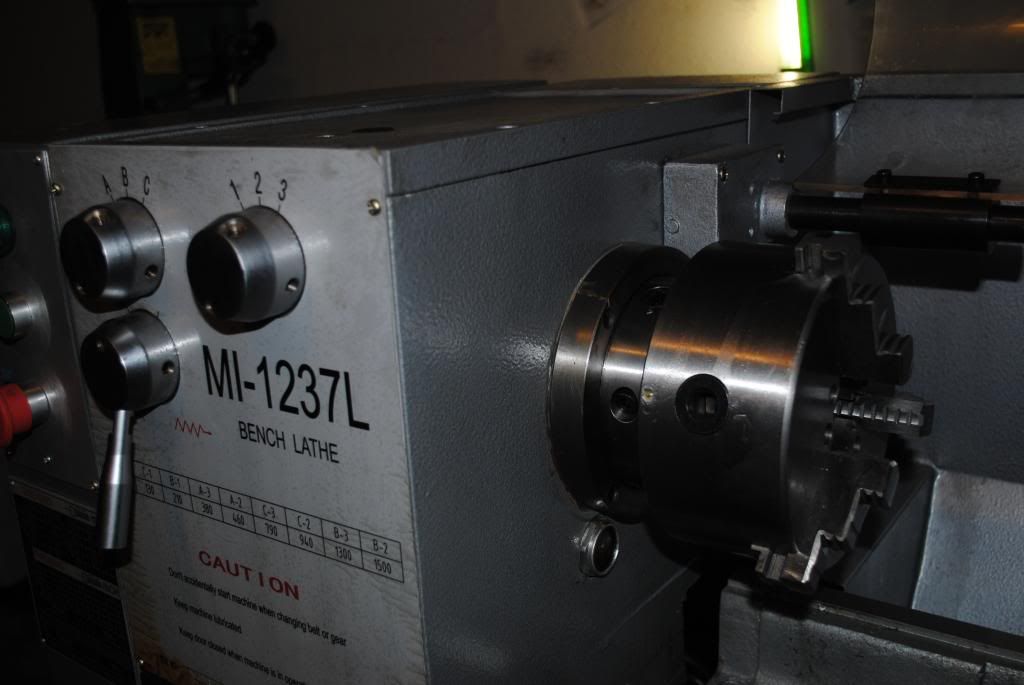

I just placed an order for an MI-1237L gearhead lathe. Its the newest version of their older bz-239/cz-239 machines. 12 inch swing, 37 inches between centers, d1-4 camlock spindle, 1.5 inch spindle bore, back gear, quick change gearbox for spindle speeds, quick change gearbox for feed/threading, and comes with a 4 jaw, 3 jaw, steady, follow, backplates, driving plate, centers, and a big steel stand!

It left Toledo, OH yesterday en-route to Roswell, NM

MI-1237L: http://www.smithy.com/lathe-gear-drive/mi-1237