Page 1 of 1

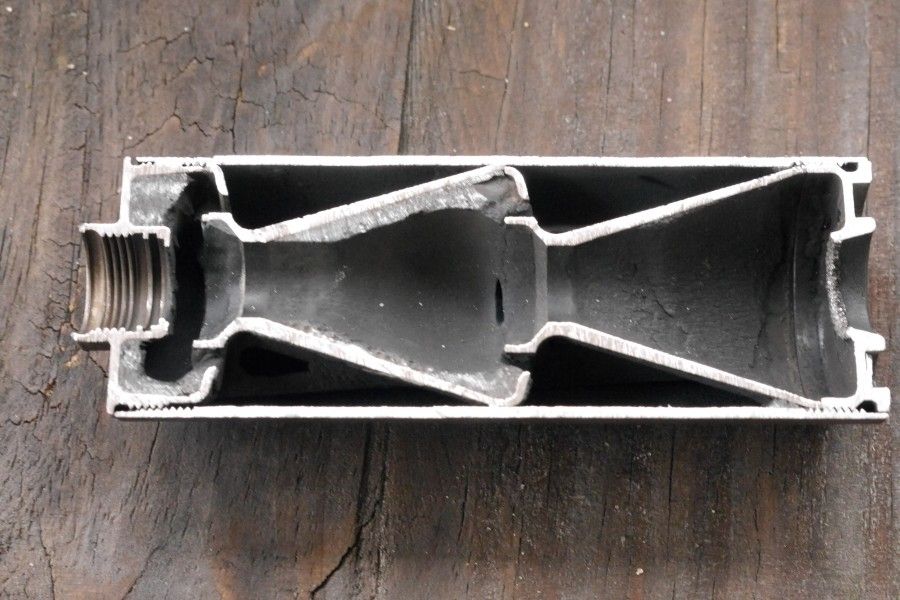

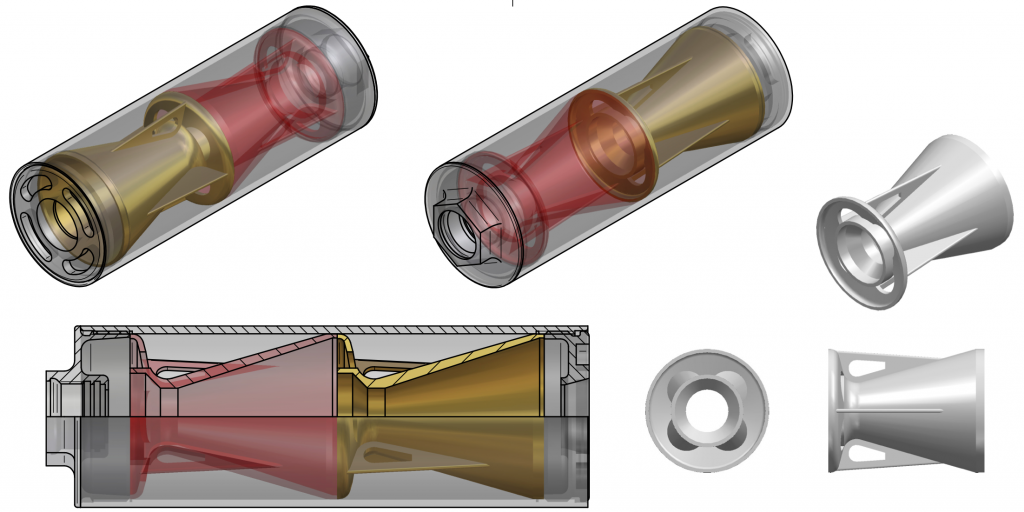

Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 1:36 am

by gunny50

Gents,

Do not know if it had been posted before

I found picture below is an article by Nick Leghorn , "Kevin Brittingham: Quick-Attach Silencers are Dead"

He talkes about the moment where he talks with a German engineer working at S&W after testing the 2 baffle MPX silencer in where that engineer says. “Every gun should have one of these”

its a long K - cone in the can not the known 60 degree as most use.

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 6:32 am

by Historian

Your photo reminded me of seeing a jazz trumpeter who with small

sound produced loud ... and great ... music.

Could there be any noticeable difference if this unit were attached to a barrel

in the reversed direction? Like a jazz trumpeter blowing into the horn

with a loud sound and getting a hiss out?

This rambling suggests that one should not write anything seriously before

the first two cups of espresso.

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 6:39 am

by gunny50

Historian wrote:Your photo reminded me of seeing a jazz trumpeter who with small

sound produced loud ... and great ... music.

Could there be any noticeable difference if this unit were attached to a barrel

in the reversed direction? Like a jazz trumpeter blowing into the horn

with a loud sound and getting a hiss out?

This rambling suggests that one should not write anything seriously before

the first two cups of espresso.

Historian,

Speaking of trumpets I do have a silencer for my trumpet, would that be a 200 USD ticket as well?

Its a nice one, can be used with electronic selectors , sound modes and input, so one can have hiss music nice and sweet while memorizing notes and text.

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 10:59 am

by a_canadian

I'm puzzled by this photo. What's holding the rear K in place besides filth and wishful thinking? The front K seems to be threaded to the tube, but the rear shows no visible means of support except the front perimeter of the cone, nothing to retain nor to align the narrower end. What am I missing? Could it be that the front and rear baffles are attached somehow and that the cross-section saw cut just happened to go through two vent holes in the rear face of the front baffle? If those are vents, well, they're pretty close to useless with all the crud in there. I'm sensing a fair bit of tongue in cheek regarding how this should be on every gun...

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 11:35 am

by gunny50

a_canadian wrote:I'm puzzled by this photo. What's holding the rear K in place besides filth and wishful thinking? The front K seems to be threaded to the tube, but the rear shows no visible means of support except the front perimeter of the cone, nothing to retain nor to align the narrower end. What am I missing? Could it be that the front and rear baffles are attached somehow and that the cross-section saw cut just happened to go through two vent holes in the rear face of the front baffle? If those are vents, well, they're pretty close to useless with all the crud in there. I'm sensing a fair bit of tongue in cheek regarding how this should be on every gun...

Take a good and long look, they are K's so front plate rests agains the rear of the first baffle.

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 11:41 am

by a_canadian

Okay, so those are vent slots in the rear face of each baffle. Fair enough. But with the tapered entry of the bore and the complete lack of cross-bore venting, why would such baffles provide even adequate suppression? Seems likely they'd be rather inefficient.

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 12:06 pm

by gunny50

gunny

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 12:09 pm

by gunny50

a_canadian wrote:Okay, so those are vent slots in the rear face of each baffle. Fair enough. But with the tapered entry of the bore and the complete lack of cross-bore venting, why would such baffles provide even adequate suppression? Seems likely they'd be rather inefficient.

When one reeds the information as SIG, the can is used WET.

And looking at the crud inside the cut model, it seams that it vents to one side more than the other

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Fri Aug 15, 2014 12:34 pm

by a_canadian

Well doesn't just about any design shoot quite quietly when wet? Put an ounce of wire pulling gel into a washer and spacer can and it should be really quiet for a shot or two.

Re: Sectioned S&W MPX 2 K can

Posted: Sat Aug 16, 2014 10:54 am

by Meche_03

Well, I would have to agree, every gun should come with a silencer from the factory. It is probably not the most effective design but for a short, subsonic, pistol caliber it probably is great compared to no silencer.

Re: Sectioned S&W MPX 2 K can

Posted: Sat Aug 16, 2014 11:22 am

by Capt. Link.

A dry can is designed to lower pressure through its ability to retain hot gases for the longest time possible allowing time to cool and expand.Size limitations come into effect with Low pressures and large bores.

A wet suppressor works on thermodynamic principles to reduce pressure through energy conversion into vapor.Large bores are not as much of a issue because of the density of the vapor and the heat of combustion provides work where high pressure is not available to drive baffles.

I prefer wet cans over dry in most cases.They can be smaller and lighter with a high degree of suppression.The non K type baffles shown I bet works very well when charged. It would cause much debate if it was not identified as a wet baffle and yet work well in such a small package.

The internal construction of dry cans are the limiting factor when a coolent is present so a washer style suppressor may not provide as much suppression as you hope wet. I hope someday you may get your chance to experiment with these much understood and underrated suppressors.

Gunny many thanks for the thought stirring photos.Have you shot either of the two suppressors or ever built a wet can.

Re: Sectioned S&W MPX 2 K can

Posted: Sat Aug 16, 2014 10:30 pm

by Meche_03

Does anyone now how those baffle are made? I would guess they are die cast or metal injected moldings if the volume of product was there. Mag or All alloy. I just guessing due to the outer surface slots and ribs......casting would be really cheap if the quantity was significant. The could be machined but at a price point.

Re: Sectioned S&W MPX 2 K can

Posted: Sun Aug 17, 2014 1:10 pm

by gunny50

Meche_03 wrote:Does anyone now how those baffle are made? I would guess they are die cast or metal injected moldings if the volume of product was there. Mag or All alloy. I just guessing due to the outer surface slots and ribs......casting would be really cheap if the quantity was significant. The could be machined but at a price point.

Due to form I 'm pretty sure its a cast.

Same as what they used for the long MPX compensator model.

This is done by many Silencer companies.

When reading online it is mentioned that it is a High Nickel content alloy.

Casting may sound cheap but remember that mass production parts like these will set you back good moneys on tooling and moulds.

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Sun Aug 17, 2014 1:14 pm

by gunny50

Capt. Link. wrote:

Gunny many thanks for the thought stirring photos.Have you shot either of the two suppressors or ever built a wet can.

Capt. No I have not shot the pistol or MPX with SIG can.

I do however make wet and whipped cans.

I love wirepulling Gel in these.

Short, small, light, compact and relatively quiet for such a small package. I have them in 30 and 35mm.

Model I make has a special wet media distribution chamber. Fill that, shake shortly and ready for use.

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Sun Aug 17, 2014 1:22 pm

by gunny50

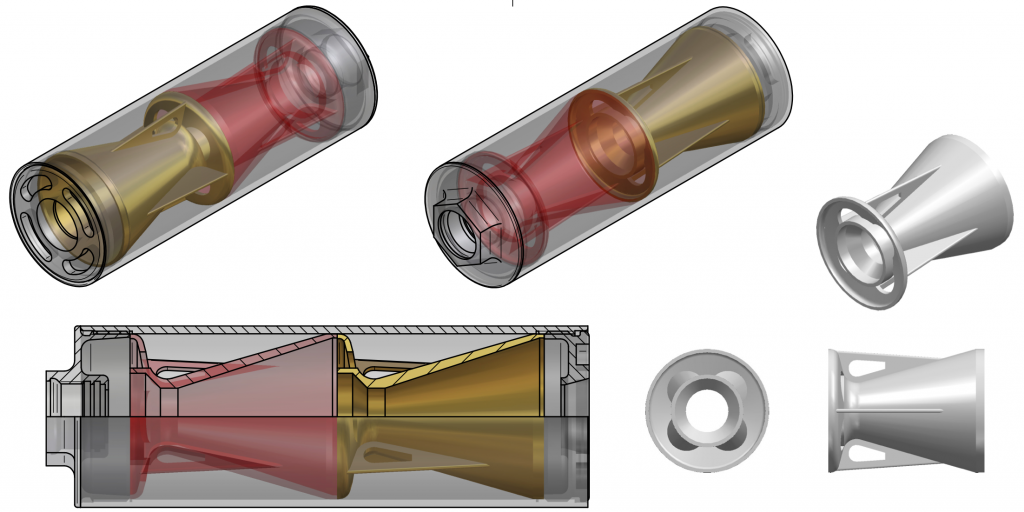

Quick rendering

Traced Sectioned picture.

35mm Diameter tube 1,5mm wall 99mm long as Advertised (cylindrical part) - K's 40mm long.

Gunny

Re: Sectioned S&W MPX 2 K can

Posted: Sun Aug 17, 2014 3:33 pm

by Capt. Link.

The art work speaks for itself wish I had that communication skill.

I have no illusions on the performance but the simplicity is very attractive.

Re: Sectioned S&W MPX 2 K can

Posted: Mon Aug 18, 2014 10:43 pm

by Meche_03

I totally agree, there is a high up front cost to die casting. I would think the break even cost point vs machining would be rather low due to this design.

I'm not sold on the nickel as a base metal. There are a few nickels that can be diecast or vacuum cast but they are typically very expensive. Though if metal injection molding was done it would be more likely. I could even see nickle coating Al or Al/Zn to increase surface toughness.

Do you have the design modeled in a cad package? I find it interesting that the baffle is remarkably similar to a solid fuel rocket nozzel but with a flow restriction on the intake side of the Laval nozzle.

Re: Sectioned S&W MPX 2 K can

Posted: Mon Aug 18, 2014 10:43 pm

by Meche_03

I totally agree, there is a high up front cost to die casting. I would think the break even cost point vs machining would be rather low due to this design.

I'm not sold on the nickel as a base metal. There are a few nickels that can be diecast or vacuum cast but they are typically very expensive. Though if metal injection molding was done it would be more likely. I could even see nickle coating Al or Al/Zn to increase surface toughness.

Do you have the design modeled in a cad package? I find it interesting that the baffle is remarkably similar to a solid fuel rocket nozzel but with a flow restriction on the intake side of the Laval nozzle.