Another Review/critique request. 9mm boosted can.

Another Review/critique request. 9mm boosted can.

Please review/critique my design for a 9mm, boosted suppressor. Currently modeled to have 7075 aluminum K baffles, titanium tube (0.045 wall after machining), titanium booster assembly/endcap and an aluminum muzzle endcap. Stainless steel booster.

More views and/or detail available. I'm not showing any threads because I dicked up my Inventor files somewhere, but I was planning something like 24 TPI on the endcaps given the thin wall thickness of the tube. Probably 20 on assembly of the endcap and booster retainer.

Is 5 baffles enough? Do you think this would be effective on 300 blackout subs? I haven't modeled it but I would plan to make another "booster retainer" (blue grey part) that would be a solid mount for use on a carbine.

More views and/or detail available. I'm not showing any threads because I dicked up my Inventor files somewhere, but I was planning something like 24 TPI on the endcaps given the thin wall thickness of the tube. Probably 20 on assembly of the endcap and booster retainer.

Is 5 baffles enough? Do you think this would be effective on 300 blackout subs? I haven't modeled it but I would plan to make another "booster retainer" (blue grey part) that would be a solid mount for use on a carbine.

Last edited by Kuraki on Wed Dec 31, 2014 8:57 am, edited 1 time in total.

Re: Another Review/critique request. 9mm boosted can.

Crap I just realized those dowels will not leave clearance for a spring.

I've never actually seen one of these in person. How do they typically prevent the suppressor from just spinning around on the booster?

I've never actually seen one of these in person. How do they typically prevent the suppressor from just spinning around on the booster?

Re: Another Review/critique request. 9mm boosted can.

Kuraki wrote:Crap I just realized those dowels will not leave clearance for a spring.

I've never actually seen one of these in person. How do they typically prevent the suppressor from just spinning around on the booster?

one solution would be a setscrew in booster housing.

Google silencer boosters. you'll see.

Gunny

Re: Another Review/critique request. 9mm boosted can.

So the cup point of the set screw interfaces with the radial cuts on the flange of the booster? Isn't there a danger of it indexing during cycling and not returning to the correct orientation? How much linear travel is there typically?

That's what I couldn't ascertain from googling.

That's what I couldn't ascertain from googling.

Re: Another Review/critique request. 9mm boosted can.

I have short pins in my booster assembly and never had any rotation issues............http://imageshack.us/a/img513/415/20121001183635911.jpg

Re: Another Review/critique request. 9mm boosted can.

Ok, perfect. Thanks guys.

Re: Another Review/critique request. 9mm boosted can.

Here's my thoughts. I'm no expert so others may pick them apart & we'll both learn:

1. 5 K's as drawn won't do the job -at least not if you're going for Hollywood.

2. The K's as drawn have a lot of room for improvement.

... They are ~50° vs the 60° angle most people use. They're too long so changing that angle will gain you some length

... The cone & the base meet at too sharp an angle. The base needs some taper & not cut flat like that - or - there needs to be a decent radius where they meet. As those are - esp if AL - they're likely to snap.

... The walls for the cone part look to be about 0.080". I'd target around 0.055" max

... I wouldn't put the steps to click/snap them together. The crud is going to the outside through the port anyway so you aren't keeping anything clean. Leave clearance and use that area to better profile the face.

... The 'snout' on the face (no idea what it should be called) is too thin/sharply angled. Look at the thin sharp point left where the scoop is milled. That AL won't last long.

... The 'dished out' area around the face should be much wider. Again, skip the "clicky" and there's room to make that much wider toward the outside.

... The scoop looks a little small. Use at least a 3/8 tool there & see how it looks. That looks like a 1/4"

3. How are you planning to make a 0.414" bore? Are you rounding up from a 10.5mm drill/reamer? I can tell you how I arrived at 0.413" for mine - I used a Z drill because I wanted slightly more than the 0.051" clearance I'd have with a 13/32 drill.

4. If you're going to machine some Ti for the build, why not do the baffles in it too? I can see avoiding it altogether & going w/ AL instead, but why mix the two materials if you're going thru the trouble of using it for half? You'll actually have to cut the inside of the cones vs using a countersink like in Whisperfan's tutorial. 300 BLK subs are mild, but why not have the insurance that ammo won't get mixed & tear it up? You can't look at a loaded round with a SMK bullet and tell if it's a 125gr or 220 gr (I specifically load 208 gr AMAX or MBC hard cast subs for that reason - you can tell a 208 AMAX from a 110 gr VMAX just by looking). Of course a high velocity 300BLK round might still blow it up - no idea since I use a .30 cal rifle can on mine. 9mm & 300BLK subsonic are roughly the same pressure but the 300BLK has a lot more powder to burn so I think you're going to be looking at a much higher internal temperature. I think Ti baffles would hold up better. If you do accidentally load a high velocity round that's almost double the pressure and more than 3x the powder to burn. Ti baffles would have a better chance of surviving at least.

5.

6. Why the cone shaped endcap? You're moving internal volume external with that. Just a guess, but wouldn't that project sound like the bell on a trumpet? Consider using the entire length of the tube and getting another K in there.

7. It looks like you're trying to copy some parts of a Ti-Rant - dimensions, outside appearance, small cone on inside of endcap, etc, but you're missing the most important part. Those are probably the most efficient 9mm K baffles ever made and they shove what 7 or 8 in that same amount of space? Maybe their booster is shorter too but the baffles definitely are.

Not trying to be negative. I like your drawings & you're on the right path. I really don't think you'll be happy with it though. I don't know a whole lot about commercial cans & who makes what. Are there commercial cans with only 5-6 K baffles and how do those compare to others? If there is one out there that performs well, maybe that's a better starting point?

1. 5 K's as drawn won't do the job -at least not if you're going for Hollywood.

2. The K's as drawn have a lot of room for improvement.

... They are ~50° vs the 60° angle most people use. They're too long so changing that angle will gain you some length

... The cone & the base meet at too sharp an angle. The base needs some taper & not cut flat like that - or - there needs to be a decent radius where they meet. As those are - esp if AL - they're likely to snap.

... The walls for the cone part look to be about 0.080". I'd target around 0.055" max

... I wouldn't put the steps to click/snap them together. The crud is going to the outside through the port anyway so you aren't keeping anything clean. Leave clearance and use that area to better profile the face.

... The 'snout' on the face (no idea what it should be called) is too thin/sharply angled. Look at the thin sharp point left where the scoop is milled. That AL won't last long.

... The 'dished out' area around the face should be much wider. Again, skip the "clicky" and there's room to make that much wider toward the outside.

... The scoop looks a little small. Use at least a 3/8 tool there & see how it looks. That looks like a 1/4"

3. How are you planning to make a 0.414" bore? Are you rounding up from a 10.5mm drill/reamer? I can tell you how I arrived at 0.413" for mine - I used a Z drill because I wanted slightly more than the 0.051" clearance I'd have with a 13/32 drill.

4. If you're going to machine some Ti for the build, why not do the baffles in it too? I can see avoiding it altogether & going w/ AL instead, but why mix the two materials if you're going thru the trouble of using it for half? You'll actually have to cut the inside of the cones vs using a countersink like in Whisperfan's tutorial. 300 BLK subs are mild, but why not have the insurance that ammo won't get mixed & tear it up? You can't look at a loaded round with a SMK bullet and tell if it's a 125gr or 220 gr (I specifically load 208 gr AMAX or MBC hard cast subs for that reason - you can tell a 208 AMAX from a 110 gr VMAX just by looking). Of course a high velocity 300BLK round might still blow it up - no idea since I use a .30 cal rifle can on mine. 9mm & 300BLK subsonic are roughly the same pressure but the 300BLK has a lot more powder to burn so I think you're going to be looking at a much higher internal temperature. I think Ti baffles would hold up better. If you do accidentally load a high velocity round that's almost double the pressure and more than 3x the powder to burn. Ti baffles would have a better chance of surviving at least.

5.

Not sure I understand this. Why not just buy .049" wall tube if that's what you want? I'm having a hard time backing into your dimensions trying to figure out how you're coming up with 1.360" OD & 1.270" ID from a standard size of tubing. All I can figure is you plan to start with a thicker walled 1.375" tube and then turn the outside and bore the inside. Maybe consider using 1.375" x .065" wall tubing. That would give you a [calculated] 1.245" ID and you can turn the OD down some if you want - or have a little more meat for coarser threads....titanium tube (0.045 wall after machining)...

6. Why the cone shaped endcap? You're moving internal volume external with that. Just a guess, but wouldn't that project sound like the bell on a trumpet? Consider using the entire length of the tube and getting another K in there.

7. It looks like you're trying to copy some parts of a Ti-Rant - dimensions, outside appearance, small cone on inside of endcap, etc, but you're missing the most important part. Those are probably the most efficient 9mm K baffles ever made and they shove what 7 or 8 in that same amount of space? Maybe their booster is shorter too but the baffles definitely are.

Not trying to be negative. I like your drawings & you're on the right path. I really don't think you'll be happy with it though. I don't know a whole lot about commercial cans & who makes what. Are there commercial cans with only 5-6 K baffles and how do those compare to others? If there is one out there that performs well, maybe that's a better starting point?

--------------------------------------

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

Re: Another Review/critique request. 9mm boosted can.

Thanks CMV, that's exactly the kind of feed back I was hoping for.

1-2: I modeled the K from pictures. I didn't understand the point of a taper on the base, but I do understand a radius. I will redraw based on your suggestions. Yes, it's .250, I can bump to .375.

3. I will single point bore it.

4. TI vs Aluminum. I've though about the one end cap after posting and decided to change that to TI. The reasons for Aluminum baffles would be mostly cost. Tube and short solid drops seem to be easy to find on Ebay for reasonable cost, but bar is a lot more iffy. AL is also lighter. The machining of the Ti is not a concern at all.

I can not mix up 300 subs and supers. I do not load supers. Period. No use for them. And, even if I did, my subs are all 245 grain coated lead flat nose bullets, easy to distinguish.

5. Yes, that's exactly it. Turned and bored .065" tubing. I learned from building my Ti .30 cal can that the tubing isn't anything close to straight. Yes I can single point bore a 7.5" long tube.

6. Are you referring to the external cone or the internal cone? Or both? The internal cone is simply to use the endcap as a cone baffle, the external is simply to reduce weight further.

7. Maybe? I've looked at a lot of pictures but nothing in particular, obviously I didn't count the number of baffles I will shorten the baffles with your suggestions as well as shorten the booster, since the suggestions above yours will allow me to take about .5" out of it.

I will shorten the baffles with your suggestions as well as shorten the booster, since the suggestions above yours will allow me to take about .5" out of it.

I took it as constructive, and it's exactly why I posted before making chips. I don't have any experience with any higher end commercial cans either. I'm basically going off of pictures and what I've gleaned from the forum.

Thanks.

1-2: I modeled the K from pictures. I didn't understand the point of a taper on the base, but I do understand a radius. I will redraw based on your suggestions. Yes, it's .250, I can bump to .375.

3. I will single point bore it.

4. TI vs Aluminum. I've though about the one end cap after posting and decided to change that to TI. The reasons for Aluminum baffles would be mostly cost. Tube and short solid drops seem to be easy to find on Ebay for reasonable cost, but bar is a lot more iffy. AL is also lighter. The machining of the Ti is not a concern at all.

I can not mix up 300 subs and supers. I do not load supers. Period. No use for them. And, even if I did, my subs are all 245 grain coated lead flat nose bullets, easy to distinguish.

5. Yes, that's exactly it. Turned and bored .065" tubing. I learned from building my Ti .30 cal can that the tubing isn't anything close to straight. Yes I can single point bore a 7.5" long tube.

6. Are you referring to the external cone or the internal cone? Or both? The internal cone is simply to use the endcap as a cone baffle, the external is simply to reduce weight further.

7. Maybe? I've looked at a lot of pictures but nothing in particular, obviously I didn't count the number of baffles

I took it as constructive, and it's exactly why I posted before making chips. I don't have any experience with any higher end commercial cans either. I'm basically going off of pictures and what I've gleaned from the forum.

Thanks.

- daviscustom

- Silent But Deadly

- Posts: 925

- Joined: Mon May 26, 2008 4:40 pm

- Location: Fly-over Country

Re: Another Review/critique request. 9mm boosted can.

Any reason why you couldn't use smaller diameter pins to make room for your spring? I kinda like the idea of hardened guide pins for the front of the piston to ride on if you can maintain concentricity to the bore.....may be a corrosion issue, I assume stainless dowel pins are available. Smaller diameter pins would also decrease weight slightly.

The myopic majority will be our republic's undoing.

Re: Another Review/critique request. 9mm boosted can.

Kuraki

Make the pins SHORT just a little shorter that the front-plate of the booster piston, you do not need 4 one would be enough.

That way you have room for your spring and the spring does not contact the pin when closed.

Setscrew to the side does the same as 1 pin in the bottom of your piston housing.

It will give you the adjustable option to adjust your POI in the direction of your POA.

Gunny

Make the pins SHORT just a little shorter that the front-plate of the booster piston, you do not need 4 one would be enough.

That way you have room for your spring and the spring does not contact the pin when closed.

Setscrew to the side does the same as 1 pin in the bottom of your piston housing.

It will give you the adjustable option to adjust your POI in the direction of your POA.

Gunny

Re: Another Review/critique request. 9mm boosted can.

Thanks gunny.

Here's the updated version. Trying to take all suggestions into account. All aluminum now (steel booster). Projected 11 oz weight. Baffles all have .060" walls. Added 5 degree taper to base wall. .030" radius to cone/base junction. Cone is 50 degrees. Stuffed 8 into 8.5" OAL.

Here's the updated version. Trying to take all suggestions into account. All aluminum now (steel booster). Projected 11 oz weight. Baffles all have .060" walls. Added 5 degree taper to base wall. .030" radius to cone/base junction. Cone is 50 degrees. Stuffed 8 into 8.5" OAL.

Last edited by Kuraki on Wed Dec 31, 2014 8:57 am, edited 1 time in total.

Re: Another Review/critique request. 9mm boosted can.

You went a little too far on the angle correction. That's what I'd call a 100° cone. The ° people use to describe a cone shape here is the overall angle of both planes, not one to bore line. Where you have 50° called out on the print, you want that 30°. Someone else will have to tell you if ± 5° or 10° matters, but I'll go out on a limb & say +20° probably does. You can make your rear endcap square & get rid of that funnel and make baffle #8 a hair shorter to fit inside the endcap. That will give you the extra length you need for a better angle on the baffles.

Cut your port & scoop in 2 operations. You can do it in one like you have drawn & what's in Whisperfan's tutorial, but you can see the interference you'll have. Even though it's 2 op's, there is 0 setup to changing from one to the other and the cuts are quick. I use my rotary table (about all it's good for since it's a POS) but you could also clamp your other chuck on the mill table to hold the baffles. Then you just pop them in & out & it goes quick. Do all the scoops, change to a square endmill & do all the ports.

Cut your port & scoop in 2 operations. You can do it in one like you have drawn & what's in Whisperfan's tutorial, but you can see the interference you'll have. Even though it's 2 op's, there is 0 setup to changing from one to the other and the cuts are quick. I use my rotary table (about all it's good for since it's a POS) but you could also clamp your other chuck on the mill table to hold the baffles. Then you just pop them in & out & it goes quick. Do all the scoops, change to a square endmill & do all the ports.

--------------------------------------

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

-

a_canadian

- Silent But Deadly

- Posts: 1204

- Joined: Fri Oct 11, 2013 3:09 pm

Re: Another Review/critique request. 9mm boosted can.

I'm not completely sure what CMV is saying about cutting the rear endcap square... but my comment on the end closer to the barrel would be that there is little to no gap between the initial chamber and the first K baffle face and that ought to be resolved somehow. You're not taking advantage of the face profile for gas redirection with the first baffle, so its face profile is useless or close to it. I'd suggest spacing the first baffle at least 0.30" forward from the displayed position so as to actually scoop pressure away from the bore line with that baffle face. Either that or make an initial blast baffle. Many here have suggested that the first, and perhaps last baffle as well ought to be symmetrical in the name of accuracy. Not sure if that's a factor, but maximizing efficiency means using every bit of geometry you can to get the most pressure away from the bore line. That first K isn't doing that.

And yeah, though a conical front cap may look cool from the outside, it's wasting volume. If you're not going to fit a smaller K cone into that space and have a flat front 'washer' baffle (the front cap machined flat) then at least put the front cap's lips closer to the end of the tube with a shallower cone or completely flat.

And yeah, though a conical front cap may look cool from the outside, it's wasting volume. If you're not going to fit a smaller K cone into that space and have a flat front 'washer' baffle (the front cap machined flat) then at least put the front cap's lips closer to the end of the tube with a shallower cone or completely flat.

Re: Another Review/critique request. 9mm boosted can.

Ok, changed the angle, which made them longer. Extended a sleeve from the barrel/mount end .500" to space the first baffle out, modified the muzzle end cap so it's flat, and if I modify 1 K baffle on the cone end it will insert inside that.

But then I'm down to 6 baffles at the same 8.5" OAL. I don't think I can squeeze any more room out of the booster, especially not enough to get another baffle inside.

Am I better off with 8 baffles (actually could probably get 9 with the muzzle end cap modification) of the 100 degree included angle, or 6 with the 60 degree included angle?

Imagine the last baffle nested inside the endcap instead of just piled up like it is. Here they are side by side.

But then I'm down to 6 baffles at the same 8.5" OAL. I don't think I can squeeze any more room out of the booster, especially not enough to get another baffle inside.

Am I better off with 8 baffles (actually could probably get 9 with the muzzle end cap modification) of the 100 degree included angle, or 6 with the 60 degree included angle?

Imagine the last baffle nested inside the endcap instead of just piled up like it is. Here they are side by side.

Last edited by Kuraki on Wed Dec 31, 2014 8:58 am, edited 1 time in total.

-

quietoldfart

- Senior Silent Operator

- Posts: 104

- Joined: Mon Jan 27, 2014 2:28 pm

- Location: France

Re: Another Review/critique request. 9mm boosted can.

There is a limit to the 'more is better' approach with K baffles. In my tinkering I found that long K baffles with sort-of-okay porting (I was learning, still am of course) in a very long can (about 11" OAL with 3.5" over-the-barrel, the barrel ported) made for adequate but not stellar noise reduction on my old long-barreled .22"LR pistol. I've settled on an 8" tube with 7 tiny K baffles, nested together in a 3.5" portion of the tube with only a tiny spacer tube between muzzle and first K. Performance with the 3" shorter tube, with vastly smaller baffles, is superior to a very considerable degree in terms of both noise suppression efficiency and in handling. Smaller is better in this case. Of course the K shaping and porting are superior, but not a world of difference there, just somewhat better. I wouldn't want less than the 3.5" of K volume, but more seems unnecessary.

I recently thought to follow a couple of industry experts' advice and milled off the faces of my rather sharply pointed cones on the K faces, offering a flatter profile on the faces. This was said to help in getting the gas stream off-bore more efficiently than a very thin edged funnel shape. Wrong. Volume went up to my ears, and measured about 3 to 4dB on my cheap sound meter. So I'll be making a new set of baffles with long funnels along the bore to get back to the very quiet suppression I was enjoying. It's still quiet, just not so quiet as it was. My answer to the experts in this regard is that such a recommendation may depend on calibre. Perhaps it works for more high-pressure ammunition than subsonic .22"LR? Or perhaps it works for this calibre but in a muzzle-mounted suppressor, not a hybrid integrated suppressor? Whatever the case, it doesn't work for my application.

Anyway, back to your case. I would suggest squinting a bit as you look at the two pictures. When I do that, blurring them out somewhat, I see what looks like a considerable air volume loss with the 8 K version. Losing that much more air is not desirable. Not sure how you'd calculate the actual remaining air volume in each to compare. Perhaps your CAD type program has that function? But you definitely do not want to lose too much air volume just to get more baffles in the tube. Because my K baffles are very tiny, the proportional strength of the 7075 aluminum to their size is quite high, meaning I was able to turn them down rather thin. If I were making them much larger I'd have to thicken the walls proportionately to prevent distortion I should think. Again, a loss of volume. So another option might be to thin the walls of your shorter K baffles, and perhaps sacrifice one, leaving 7 plus the increased blast volume you've shown in the 6 K version?

I recently thought to follow a couple of industry experts' advice and milled off the faces of my rather sharply pointed cones on the K faces, offering a flatter profile on the faces. This was said to help in getting the gas stream off-bore more efficiently than a very thin edged funnel shape. Wrong. Volume went up to my ears, and measured about 3 to 4dB on my cheap sound meter. So I'll be making a new set of baffles with long funnels along the bore to get back to the very quiet suppression I was enjoying. It's still quiet, just not so quiet as it was. My answer to the experts in this regard is that such a recommendation may depend on calibre. Perhaps it works for more high-pressure ammunition than subsonic .22"LR? Or perhaps it works for this calibre but in a muzzle-mounted suppressor, not a hybrid integrated suppressor? Whatever the case, it doesn't work for my application.

Anyway, back to your case. I would suggest squinting a bit as you look at the two pictures. When I do that, blurring them out somewhat, I see what looks like a considerable air volume loss with the 8 K version. Losing that much more air is not desirable. Not sure how you'd calculate the actual remaining air volume in each to compare. Perhaps your CAD type program has that function? But you definitely do not want to lose too much air volume just to get more baffles in the tube. Because my K baffles are very tiny, the proportional strength of the 7075 aluminum to their size is quite high, meaning I was able to turn them down rather thin. If I were making them much larger I'd have to thicken the walls proportionately to prevent distortion I should think. Again, a loss of volume. So another option might be to thin the walls of your shorter K baffles, and perhaps sacrifice one, leaving 7 plus the increased blast volume you've shown in the 6 K version?

Re: Another Review/critique request. 9mm boosted can.

I tied to calculate air volume with Inventor but if it's possible I can't figure out how. I think I can figure it out longhand however.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: Another Review/critique request. 9mm boosted can.

In regards to volume, in my first build (albeit a 22lr) I was disappointed with my initial results. I went back to the board. Shaved weight where I could. Nested tails into faces and snuck another baffle into the design. This, coupled with an endcap redesign, got me a total of 9 baffles in a 5.124" tube. The weights CAD gave me for the new design were less than the original. The less material equalled greater volume. I have yet to build this version so sound is theory, but if volume, cone porting and baffle faces to strip and move gases is whats needed, I think it could be worth it.quietoldfart wrote:There is a limit to the 'more is better' approach with K baffles.

Anyway, back to your case. I would suggest squinting a bit as you look at the two pictures. So another option might be to thin the walls of your shorter K baffles, and perhaps sacrifice one, leaving 7 plus the increased blast volume you've shown in the 6 K version?

I find it easier to subtract the actual baffle material volume from the cylinder it fits in.Kuraki wrote:I tied to calculate air volume with Inventor but if it's possible I can't figure out how. I think I can figure it out longhand however.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: Another Review/critique request. 9mm boosted can.

Thats exactly what I planned to do.

Re: Another Review/critique request. 9mm boosted can.

Screw it. People seem to like the Octane. I'll just do something similar. Less work than Ks anyway, no manual turning just CNC milling.

10 oz. 8.3" OAL. All aluminum.

10 oz. 8.3" OAL. All aluminum.

Last edited by Kuraki on Wed Dec 31, 2014 8:58 am, edited 1 time in total.

Re: Another Review/critique request. 9mm boosted can.

Ok. Last rev I think. Did some more looking at Omega baffles. This representation is 8.47" long, 12 oz, with 17-4 SST Omega baffles, SST piston, everything else 6061 or 7075 aluminum. Baffles are .040" thick except at the top hat, those are .062". I would cut the SST bar into 1.25x1.25 chunks, heat treat them, then 3D mill them into final form. Should be easy to clean then, just drop them in a tumbler. I like the idea of a lock ring so added that as well.

Last edited by Kuraki on Wed Dec 31, 2014 8:58 am, edited 1 time in total.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: Another Review/critique request. 9mm boosted can.

Nice artwork.

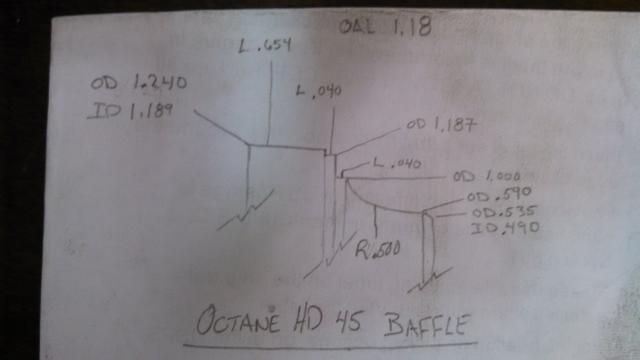

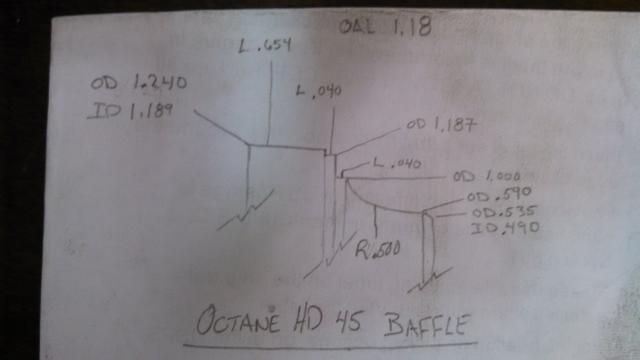

FWIW, this is a baffle from my Octane 45HD CTA stack.

I know its a larger caliber, but I thought you might like to have it.

FWIW, this is a baffle from my Octane 45HD CTA stack.

I know its a larger caliber, but I thought you might like to have it.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

- mpallett

- Elite Industry Professional

- Posts: 2876

- Joined: Mon Apr 25, 2005 9:28 am

- Location: MA

- Contact:

Re: Another Review/critique request. 9mm boosted can.

Or you could just buy a Trident and have someone jailbreak it for you.

Kuraki wrote:Ok. Last rev I think. Did some more looking at Omega baffles. This representation is 8.47" long, 12 oz, with 17-4 SST Omega baffles, SST piston, everything else 6061 or 7075 aluminum. Baffles are .040" thick except at the top hat, those are .062". I would cut the SST bar into 1.25x1.25 chunks, heat treat them, then 3D mill them into final form. Should be easy to clean then, just drop them in a tumbler. I like the idea of a lock ring so added that as well.

Over weight Telco guy with a FFL/07 for hire

Re: Another Review/critique request. 9mm boosted can.

Even if I did want to wait for a paper form and spend 5x as much, why wouldn't I crack it open myself? I have zero interest in purchasing cans, dealing with SOTs I don't know, or driving halfway across the state to deal with them.mpallett wrote:Or you could just buy a Trident and have someone jailbreak it for you.

Thanks!T-Rex wrote:Nice artwork.

FWIW, this is a baffle from my Octane 45HD CTA stack.

I know its a larger caliber, but I thought you might like to have it.

- Bendersquint

- Industry Professional

- Posts: 11357

- Joined: Sat Jan 07, 2006 7:19 pm

- Location: North Carolina

- Contact:

Re: Another Review/critique request. 9mm boosted can.

Nice drawings but don't forget the Omega baffle is still patented so you can't legally make it!Kuraki wrote:Ok. Last rev I think. Did some more looking at Omega baffles. This representation is 8.47" long, 12 oz, with 17-4 SST Omega baffles, SST piston, everything else 6061 or 7075 aluminum. Baffles are .040" thick except at the top hat, those are .062". I would cut the SST bar into 1.25x1.25 chunks, heat treat them, then 3D mill them into final form. Should be easy to clean then, just drop them in a tumbler. I like the idea of a lock ring so added that as well.

-

a_canadian

- Silent But Deadly

- Posts: 1204

- Joined: Fri Oct 11, 2013 3:09 pm

Re: Another Review/critique request. 9mm boosted can.

Isn't the situation with patents closer to 'can't legally make it... for sale'? I am not a lawyer, but from a lot of readings over the years that was my understanding of both the intent and practice of patent law, to protect the patent holder from commercial infringement. Not from hobbyist made one-offs.