Page 1 of 1

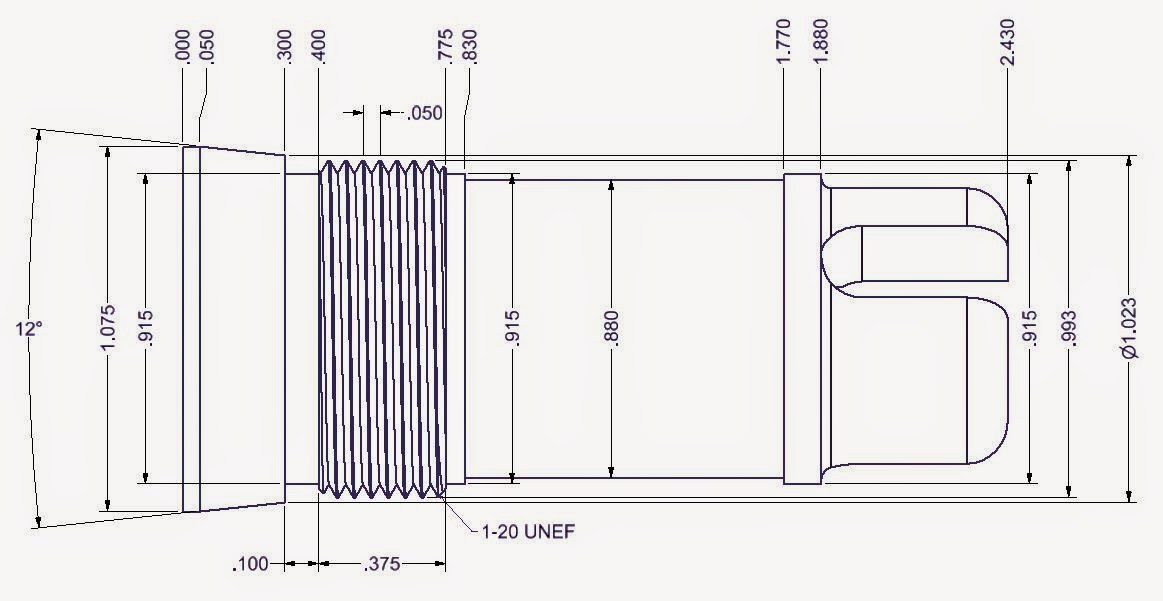

Griffin Taper Mount Comp Specs Inside

Posted: Mon Jan 05, 2015 1:11 pm

by propeine

This is as measured and modeled by me. Worth precisely what you paid for it. I had emailed Griffin asking for at least the taper and the threading and didn't get a reply. Intentionally not enough info here to build one. Don't want to step on toes just wanted to know how to interface it.

Looks like 3/8" worth of 1x20 threads with a 12 degree included angle. 6 per side. I don't have a protractor handy (can't find it) and used trig to get to this point so the 6 degrees may not be exact.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Mon Jan 05, 2015 7:14 pm

by airsix

Thanks for sharing this.

Just this weekend I was fiddling with one trying to sort it out. I'm guessing you're right on the taper being 6 degrees. I used a crappy plastic gauge and got 7 degrees as my best guess. I trust your math more than my measurement (I'll turn a test piece and check it with hi-spot dye just to confirm).

PS - I made a Griffin end-cap this weekend. Sort of. I turned the 20tpi inside threads as the final step and totally botched an otherwise perfect piece with all other operations completed. So I get to make a new one next weekend. On the bright-side now I have your measurements to use. Thanks.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Mon Jan 05, 2015 7:37 pm

by propeine

Could come up 6.5 too haha. The math is so small that a missed thousandth changes the degrees my a few tenths and measuring on the taper is hard. My plan is to chuck up the mount itself and indicate it in on the round then use a dial indicator again to match the taper with the compound. Then I'll be 100% sure it's right to my mount at least with my compound.

I'll update my drawing if the calculations come out different but I'm pretty confident.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Tue Jan 06, 2015 12:38 am

by airsix

That sounds like a brilliant way to verify the taper. I never would have thought of that!

(I have no formal machinist training)

Re: Griffin Taper Mount Comp Specs Inside

Posted: Tue Jan 06, 2015 7:58 am

by propeine

airsix wrote:That sounds like a brilliant way to verify the taper. I never would have thought of that!

(I have no formal machinist training)

I had about 6 weeks of training 14 years ago alongside 6 weeks of mill and 6 weeks of surface grinding. I'm no "machinist" but I can spin the handles. I struggle with setups and orders of operation but that's something I think you only get with experience and 40-60 hours a week I'm making drawings not reading them.

What went wrong with your threading btw?

Re: Griffin Taper Mount Comp Specs Inside

Posted: Mon Jan 12, 2015 8:52 am

by airsix

propeine wrote:airsix wrote:

What went wrong with your threading btw?

When I bored the ID of the end-cap where it was to be threaded for the Griffin I used a cheap brazed import boring bar it flexed terribly and I ended up with a severely tapered hole.

I spent a bit of money on propper boring and inside thread tooling and turned an end-cap this time I'm very pleased with. I'm doing my work on a 7x14 mini-lathe.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Thu Dec 01, 2016 7:41 pm

by yondering

airsix wrote:

When I bored the ID of the end-cap where it was to be threaded for the Griffin I used a cheap brazed import boring bar it flexed terribly and I ended up with a severely tapered hole.

I spent a bit of money on propper boring and inside thread tooling and turned an end-cap this time I'm very pleased with. I'm doing my work on a 7x14 mini-lathe.

Two words to help with that - spring passes.

Good tooling is always better, but you still need to know how to handle tool/work deflection, especially when threading. Spring passes (taking more passes without more infeed) are generally a good idea in threading, even with a fairly rigid setup. If your cut left a taper on the part, make a spring pass or two to clear it up. Make sure the tool is sharp as well, brazed carbide is terrible for that.

Hope that helps.

And, if you didn't already remove too much material from that botched part - now is a good time to learn how to pick up an existing thread to re-cut it, you may be able to salvage the part. Shout out if you need help figuring that out.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Thu Dec 01, 2016 11:14 pm

by Bah21963

I have had this same drawing for at least a full year. I do not know where you are measuring 6 degees. When I made a thread adapter I made the taper at 12 degrees and checked it with dykem it mated up perfectly to the ga minimalist brake.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Fri Dec 02, 2016 6:38 am

by Historian

propeine wrote:Could come up 6.5 too haha. The math is so small that a missed thousandth changes the degrees my a few tenths and measuring on the taper is hard. My plan is to chuck up the mount itself and indicate it in on the round then use a dial indicator again to match the taper with the compound. Then I'll be 100% sure it's right to my mount at least with my compound.

I'll update my drawing if the calculations come out different but I'm pretty confident.

Excellent!

Remembered YouTube showing similar technique.

<<

https://www.youtube.com/watch?v=Gor1weVbtJc >>

Best.

Re: Griffin Taper Mount Comp Specs Inside

Posted: Fri Dec 02, 2016 8:23 am

by propeine

Bah21963 wrote:I have had this same drawing for at least a full year. I do not know where you are measuring 6 degees. When I made a thread adapter I made the taper at 12 degrees and checked it with dykem it mated up perfectly to the ga minimalist brake.

12 degrees on the compound? Because I have 12 included which would be 6 on the compound.