The smallest stock I can feed through my spindle is 3/4". Is that too small for a aluminum monocore? Any larger and I'd have to set up a steady rest. I'm particularly thinking about the center drilling. I can get about 2" of 1" stock behind my chuck before the MT3 taper in the spindle catches it... I don't trust my steady rest. It is an Atlas original part. I would like to work between centers as much as possible. My plan was to center drill the core, turn the exterior to the tube final ID, and ream the shell with a boring bar between centers and the tube mounted to my toolpost or compound. Once the tube was reamed I could dial in the core OD to match between centers.

Nothing there requires the steady rest except maybe threading the tube interior...and center drilling the core.

The center drill operation is scaring me. Luckily it's first...

Do I need to change my thinking?

Min diameter for 22lr monocore?

Min diameter for 22lr monocore?

YHM Phantom 30 cal, 22lr form 1 build, 45 cal form 1 in progress

Atlas 10x36

Atlas 10x36

Re: Min diameter for 22lr monocore?

Historically the 1930's .22 Parker Hale U.K. MM1 had an innercdhknives wrote:The smallest stock I can feed through my spindle is 3/4". Is that too small for a aluminum monocore? Any larger and I'd have to set up a steady rest. I'm particularly thinking about the center drilling. I can get about 2" of 1" stock behind my chuck before the MT3 taper in the spindle catches it... I don't trust my steady rest. It is an Atlas original part. I would like to work between centers as much as possible. My plan was to center drill the core, turn the exterior to the tube final ID, and ream the shell with a boring bar between centers and the tube mounted to my toolpost or compound. Once the tube was reamed I could dial in the core OD to match between centers.

Nothing there requires the steady rest except maybe threading the tube interior...and center drilling the core.

The center drill operation is scaring me. Luckily it's first...

Do I need to change my thinking?

tube diameter of .75" ( could fill it with US pennies for fun

Look at Youtube for info on "Pah.Kar 'Ale". Purportedly MM1 used

by British SOE on some of their War time devices.

Amazing what 80+ years advancement has brought.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: Min diameter for 22lr monocore?

I understand you dont want to use the rest, they're not hard to use and setup once you've done it.

If you use 1" bar stock, size for reference, you can turn the od between centers and design it so the tube doesnt need to be threaded. You should be able to use a thinner wall, too.

This way, you only have to use the steady rest for the boring and not again.

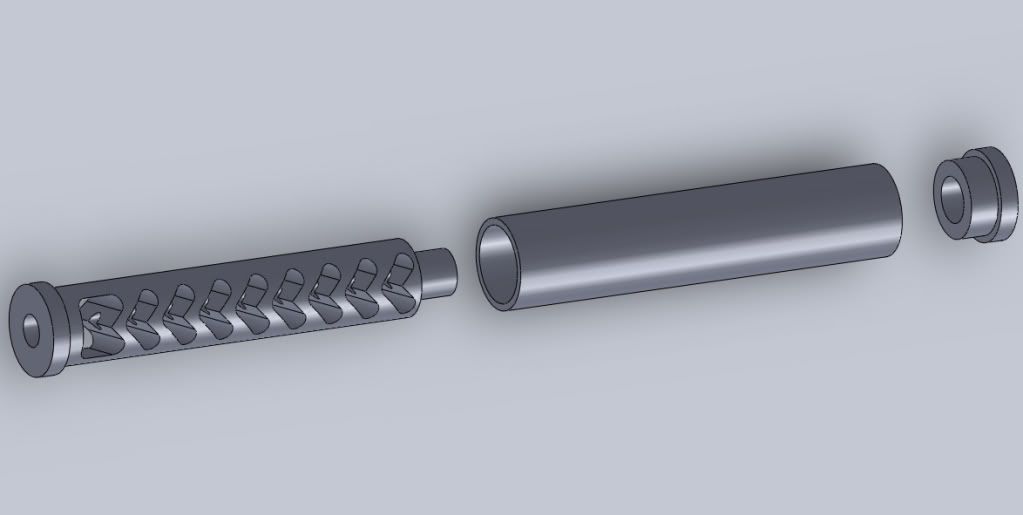

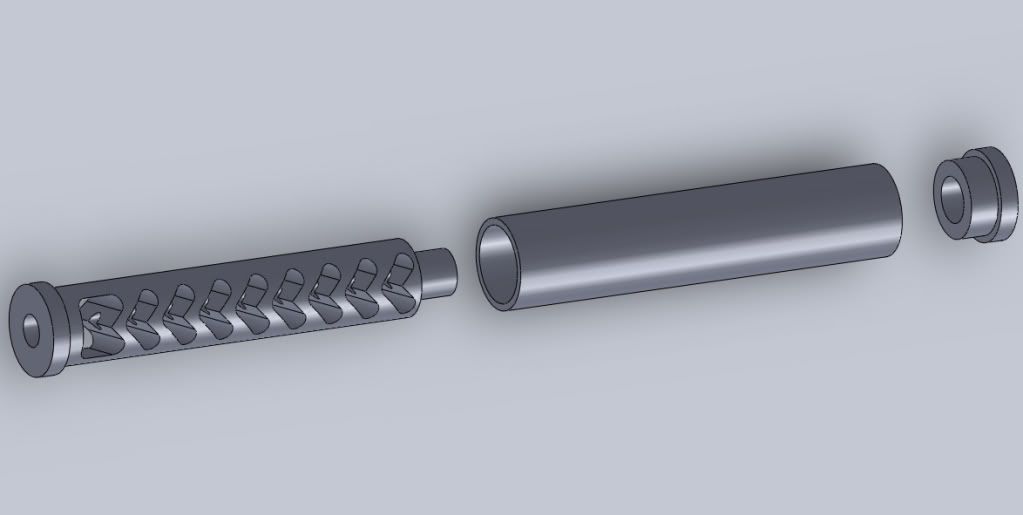

like this

If you use 1" bar stock, size for reference, you can turn the od between centers and design it so the tube doesnt need to be threaded. You should be able to use a thinner wall, too.

This way, you only have to use the steady rest for the boring and not again.

like this

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

-

a_canadian

- Silent But Deadly

- Posts: 1204

- Joined: Fri Oct 11, 2013 3:09 pm

Re: Min diameter for 22lr monocore?

Not sure I'm reading that drawing correctly, but... isn't that monocore backwards? The baffle cuts I mean. Shouldn't the V points be facing the muzzle, as in the larger hole on the right side of the drawing? As shown it looks like it may strip away some pressure, but not very well.

Re: Min diameter for 22lr monocore?

I think what you are seeing as the larger 'muzzle' bore would be threaded to attach to the stub of the monocore. The smaller bore showing on the left would be threaded for the muzzle...if I am reading it correctly.a_canadian wrote:Not sure I'm reading that drawing correctly, but... isn't that monocore backwards? The baffle cuts I mean. Shouldn't the V points be facing the muzzle, as in the larger hole on the right side of the drawing? As shown it looks like it may strip away some pressure, but not very well.

Interesting thought. I would prefer to not have aluminum threads to my muzzle, but other than that it looks like a workable design. I might also turn it around and use the endcap as the muzzle mount and reverse the baffle boring. That would be fun threading. I'm just trying to see if O could work up a proper blast baffle, even a simple coned washer, in that design...as is the first baffle is Al.

YHM Phantom 30 cal, 22lr form 1 build, 45 cal form 1 in progress

Atlas 10x36

Atlas 10x36

Re: Min diameter for 22lr monocore?

My biggest hesitation in using my steady rest is the fact that it is a 65+ year old Atlas part with a LOT of miles on it. I guess all I lost is a $6 aluminum tube if a screw it up. I assume a form 1 allows you to make mistakes in manufacturing and throw away the useless parts...surely it isn't a suppressor part if it is ruined in machining!

YHM Phantom 30 cal, 22lr form 1 build, 45 cal form 1 in progress

Atlas 10x36

Atlas 10x36

-

a_canadian

- Silent But Deadly

- Posts: 1204

- Joined: Fri Oct 11, 2013 3:09 pm

Re: Min diameter for 22lr monocore?

Ah yes, I see it now. That bigger volume at the left hand side should have tipped me off as it's plainly the blast volume. Hm, good thought on adding something more durable to it. And I'd prefer it the other way around, with the short end cap being the threaded part. Then it'd be relatively easier to thread, at least with a tap (yeah, I know, tap is a bad word around here... but some of us don't have lathes capable of threading in any way besides use of a jig each for tap and die), and could even be made of steel. Through-cut the threads using the same size thread as the barrel is threaded, probably using a slightly longer cap than shown, and it's so much simpler yet. Just a matter of trimming until the two threaded parts meet in the middle or even slip an O-ring in there to prevent back-flow from polluting the threads between muzzle and monocore. A bit less aluminum, a bit more complexity in the cut-outs, and a press-fit stainless washer bent into a V for the initial baffle. Yeah, neat idea to get around not being able to cut big threads.cdhknives wrote:I think what you are seeing as the larger 'muzzle' bore would be threaded to attach to the stub of the monocore. The smaller bore showing on the left would be threaded for the muzzle...if I am reading it correctly.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: Min diameter for 22lr monocore?

The pic I posted was to explain my idea better than with just words.

I wasn't promoting any singular aspect of the design.

I don't think you put enough faith in you steady rest. Sure it's 65+ yrs old, but it's American made iron.

The rest, having 3 fingers, is completely adjustable, that's the beauty. Just give it some practice.

Personally, I wouldn't have an issue with threading Carbon or Stainless into Aluminum. Use anti-seize, that's what it's made for. Also, I've never been pressed for time to attach or unscrew my suppressor from the host. I have plenty of time to get the threads straight.

If you're that worried, you could always press in a bushing/insert.

Yes, o-rings would be preferred in the design shown.

The bent washer is a neat idea, too.

I wasn't promoting any singular aspect of the design.

I don't think you put enough faith in you steady rest. Sure it's 65+ yrs old, but it's American made iron.

The rest, having 3 fingers, is completely adjustable, that's the beauty. Just give it some practice.

Personally, I wouldn't have an issue with threading Carbon or Stainless into Aluminum. Use anti-seize, that's what it's made for. Also, I've never been pressed for time to attach or unscrew my suppressor from the host. I have plenty of time to get the threads straight.

If you're that worried, you could always press in a bushing/insert.

Yes, o-rings would be preferred in the design shown.

The bent washer is a neat idea, too.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: Min diameter for 22lr monocore?

Old Atlas's are more rugged than many of the Chi-Coms imported today.cdhknives wrote:My biggest hesitation in using my steady rest is the fact that it is a 65+ year old Atlas part with a LOT of miles on it. I guess all I lost is a $6 aluminum tube if a screw it up. I assume a form 1 allows you to make mistakes in manufacturing and throw away the useless parts...surely it isn't a suppressor part if it is ruined in machining!

Many YouTubes on restoring them.

E.g., << https://www.youtube.com/watch?v=obvA83_EFPk >> as a starter.

I restored an Atlas 618 'door stop' and learned so much in the process.

Then I built from NOS parts found on eBay another one for fun and back up.

As for steady rests again you can find videos on their use, and in fact

modifying the 'fingers' with bearings.

One key start with steady rests is to turn a small section where the

rest will be set and lube with grease. Amazing how long a piece

you can hold and play with.

Tube can be held without a steady by using in the tail stock a free turning tapered

bull nose cone live center.

<< http://www.woodturningvideosplus.com/live-centres.html >>

<< https://www.youtube.com/watch?v=2w-l1-ZQCck >>

Plus it is a tool junkies joy to buy, spin, and if so inclined to actually use.

Best.

Re: Min diameter for 22lr monocore?

I made a 1.5" monocore for my 77/44 on a east german hobbymat lathe with 0,5" spindle bore. No worries at all. No need to thread the tube.. My suppressor was only 3parts.. a stainless monocore with just one chamber that threads into a 7075 monocore and a 316 stainless pipe as tube.. My lathe has no steadyrest and only 12" between centers so drilling the core was kind of problematic..

viewtopic.php?f=10&t=90236

viewtopic.php?f=10&t=90236

-

armalite_ar50

- Silent Operator

- Posts: 56

- Joined: Mon Oct 04, 2010 3:06 pm

Re: Min diameter for 22lr monocore?

I'll second the durability of the Atlas I have had one for over 5 years. your steady rest will be fine. worse thing that it could need would be new brass rests for centering. I have two steady rests for mine it came that way when I bought it.

One thing I figured out real fast with my old atlas is if it will fit in the lathe and you have patience you can tun it out.

Rich

One thing I figured out real fast with my old atlas is if it will fit in the lathe and you have patience you can tun it out.

Rich