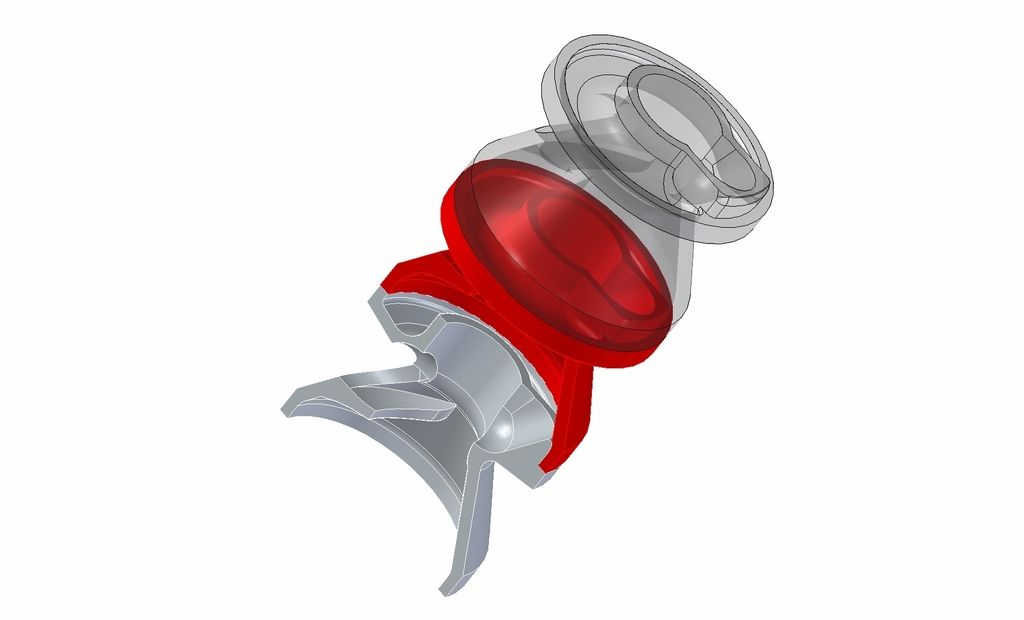

I'd use 4 or 5 baffles with vanes printed inside the grey tube with 80mm in front of the muzzle in place of the red part (view3).

Would this likely make any improvement over simple baffles without the vanes?

View 1:

View 2:

View 3:

Thanks for your encouragementT-Rex wrote:If I had your ability, in regard to multiple rev changes, I would try them all.

Record data

Determine which features held weight and revise.

You can become our own expert.

Make it modular and you can print various models for each section.

Real possibilities

The K12 has such a nice trigger! I have a MatchGuns MGH1 Hybrid for 10m match shooting. My Steyr is the LP50 5 shot for shooting silhouette. Want to keep the pop down in my backyard. I don't use the open sights for silhouette, instead a red-dot and the reason for the picatinny mount on the shroud mount.quietoldfart wrote:Per your questions on baffle design, my take on the problem is that you may be over-thinking it. My other experimentation with baffles for various airguns has shown that even simple washers and spacers are rather effective, that a well fashioned delrin monocore is better still, cones are even better, and well made K baffles best of all. I've not tried K baffles on the Pardini as it's more a problem of air volume for the barrel ports and a short baffle set in front of the muzzle, not very difficult to suppress. For anything with muzzle-and-beyond suppressor tubes I've settled on K baffles as being the clear winner for quiet shooting, particularly made rather short, about 0.55" total length so as to get more of them into the tubes with well shaped cross-bore jetting hollows carved into the faces and waists. Longer K baffles (between 0.8" and 1.125" were tried) were less efficient, the longest being the loudest.

Those look more like notchs than scoops. You've drawn notched cones. Ks direct the gas using a flat surface to gather the gas by stopping the forward flow.wasatch wrote:How do these scoops look? I drew three but could easily make it one and could alter the angle of the scoop.

He could even build a slight "ramp" to direct the gas, and leave a 270* collar around the mouth to block any counter-flow.quietoldfart wrote:...and make your scoop more prominent using that material. You don't have a lot of pressure to work with at such low FPE, so grabbing as much of that flowing air as you can from near the bore and directing it across the stream is better.

Russian; transplanted British actually, retired. Something I must have mentioned early on in my participation in these forums. Got myself a shabby little place in a slightly less damp climate.

wasatch wrote:Gunny,

The blast baffle has a stripper cone, it is the first red baffle in the pic of the assembly above.