daviscustom wrote:Cool! Is that a collet on both ends?.....is this a motor you modified the shaft on, or is it made that way? What is it's original application?

Have you been using it for long?...I worry how the bearings are going to hold up in my router.

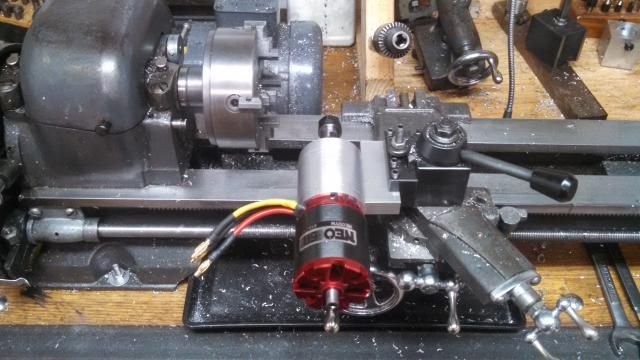

The "Collet" you see on the rear end is actually the knob on my carriage wheel.

The motor is for electric RC airplanes. I bought an ER16 collet extension, 150mm I think, and replaced the motors shaft. Obviously, the motor came with the same size, not length, shaft.

I had to build a power supply and speed control for it. Maybe, I'll try to remember and post a pic of it tonight.

The Aluminum part, attached to the QCTP, is what I fabbed. Its 4pcs, total. The rear piece mounts to the motor's faceplate, accepts the (6) body screws and covers the rear bearing. The center portion holds both bearings and accepts the mount piece for the QCTP. The front cap holds the front bearing in and the (6) screws pull the assembly together.

I used Angular Contact Bearings, to help with any side-loading. I built this with the intention of plunging, but minimal millwork is acceptable. It makes trepanning a breeze as well as any K-Baffle scoops or vent holes.

I, probably, have 50hrs of "in-use" on this lil guy. Add a couple hours of motor break-in, in which no loading occurred.

I started, like you, with my flex shaft in the QCTP boring bar holder. This was OK as long as you can understand and accept its limitations.

I have a couple 1/4" trim routers, as you used, but my centerline clearance, over the cross-slide, didn't allow for the meat the mount was going to need. I'm looking into a 9" or 10" SB so I'll make a new one for the router, at that time.

When I was making the bearing housing and caps, I off-centered the material and used the tail-stock to drill the longitudinal screw holes.

My Craftsman has the same indexing holes, as your lathe, mine being 6* apart.