Page 2 of 3

Re: 308 design critique

Posted: Thu Mar 24, 2016 2:26 pm

by silencer_kid

fishman wrote:why didnt you thread the rear cap all the way through with the threads that attach to the barrel? doing so would cut some weight.

i think for some symmetry its best to have a smooth bore transition (if the barrel threading is shorter than cap thickness). i do prefer to have end of muzzle faced flush with the cap screwed on, and then add a 45 or 60 degree crown applied from rifling edge all the way to almost the OD of the barrel. this allows the gas to escape with some symmetry into the blast chamber. now, an open end muzzle, if you study slow-mo of muzzle blasts, they still have symmetry, but adding a little "help" doesnt hurt to make it better. but hey, if the "pros" here say otherwise, you best be listening to them

Re: 308 design critique

Posted: Thu Mar 24, 2016 2:35 pm

by fishman

silencer_kid wrote:fishman wrote:why didnt you thread the rear cap all the way through with the threads that attach to the barrel? doing so would cut some weight.

i think for some symmetry its best to have a smooth bore transition (if the barrel threading is shorter than cap thickness). i do prefer to have end of muzzle faced flush with the cap screwed on, and then add a 45 or 60 degree crown applied from rifling edge all the way to almost the OD of the barrel. this allows the gas to escape with some symmetry into the blast chamber. now, an open end muzzle, if you study slow-mo of muzzle blasts, they still have symmetry, but adding a little "help" doesnt hurt to make it better. but hey, if the "pros" here say otherwise, you best be listening to them

why not just make the endcap slightly thinner than the barrel threads? then the cap will have no interference with the blast until the bullet is well out of the way.

Re: 308 design critique

Posted: Thu Mar 24, 2016 2:38 pm

by NChobbymachining

fishman wrote:why didnt you thread the rear cap all the way through with the threads that attach to the barrel? doing so would cut some weight.

That was just a modeling error, it will be bored and threaded all the way through and has been corrected on the updated model.

Re: 308 design critique

Posted: Thu Mar 24, 2016 2:50 pm

by silencer_kid

fishman wrote:

why not just make the endcap slightly thinner than the barrel threads? then the cap will have no interference with the blast until the bullet is well out of the way.

the expanding gas has lots of weird properties. its expanding (and in many cases still burning) while at the same time has vector inertia. some of it will reflect off of the cap face and cause disruption within the continuing expanding gas coming out of the muzzle. this as the bullet has already made it to baffle 1-2. you could also pocket the inside part of the cap between OD of barrel to almost the ID of the cap threading, this to remove some weight and add a little more volume to the blast chamber. nicely matched geometry to a standing wave could yield dramatic results, its just a tad tricky to do with an expanding gas (which varies) that has vector inertia.

Re: 308 design critique

Posted: Thu Mar 24, 2016 4:58 pm

by CMV

Its worth a shot. Ill coat the 7 baffles after the blast baffle and see how it holds up. Ill order some 17-4 and use that for the blast baffle.

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

Re: 308 design critique

Posted: Fri Mar 25, 2016 12:17 am

by silencer_kid

CMV wrote:

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

what about hard chrome?

Re: 308 design critique

Posted: Fri Mar 25, 2016 5:55 am

by Samson1044

using 316 SS (even 304) as your blast baffle material would work fine and I doubt that you would ever wear it out unless you spend as much shooting as you do on your house note or unless you are running it full auto all the time. 17-4 is surely stronger that 316 but unless you have it on hand I wouldn't bother.

By using Grade 9 titanium tube and grade 5 for your end caps you would drop a lot of weight , you could even use 7075 aluminum for you caps and save more weight , use a brake style adapter and that would save even more wear on the blast baffle.

Like this

http://www.griffinarmament.com/Griffin- ... -p/tmm.htm

if you made the first 3 baffles out of out of SS and the rest from 7075 you would still get thousands and thousands of rounds out of it before you started to even see any wear on the aluminum baffles and after a couple years and 4,000-5,000 rounds if they were worn you could just replace them (assuming you are not in the US because that would be against the law especially if you went around telling people about it

)

Fabricate your spacer as part of your cone , this will help with strength if you went with aluminum and help with tolerance stacking and any possible bore misalignment

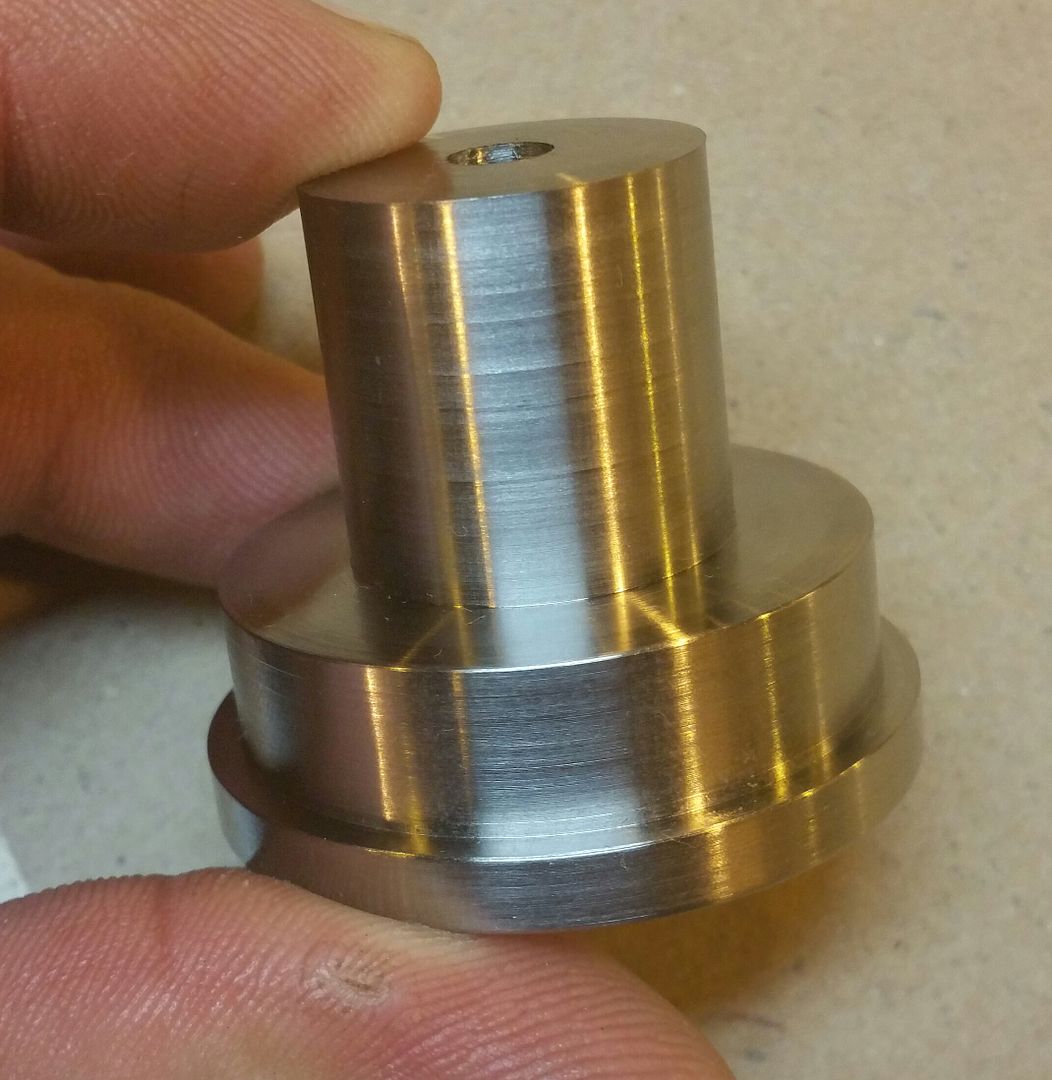

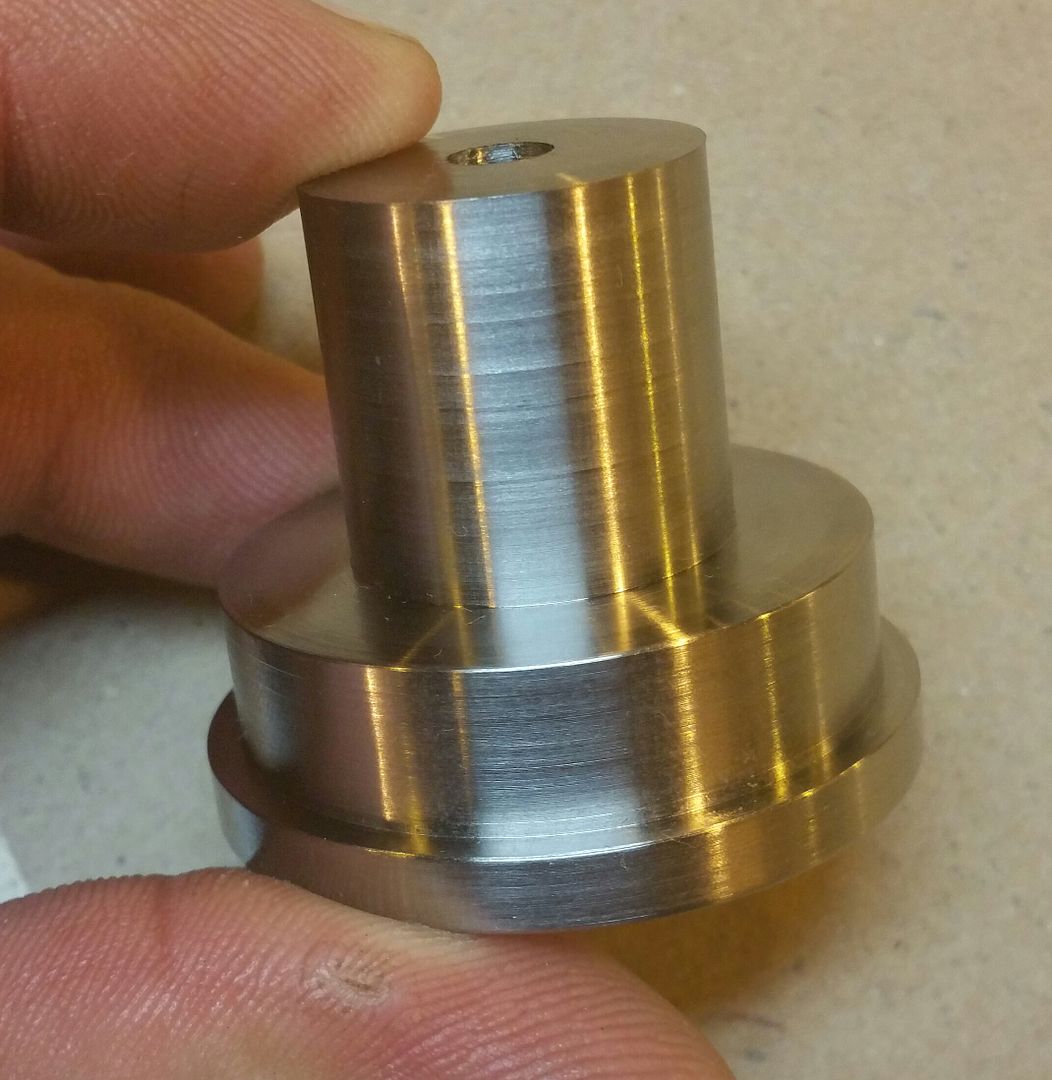

If you decide to make your rear cap from steel then you can mill or cut the meat from between the thread root of the threads to drop some weight , and even make a brake into it which is not that hard on a mill with an indexing head. for threaded caps I prefer to cut my female barrel threads first then make a male stub piece , thread it on in the chuck and then thread the male tube threads , this will ensure perfect alignment between the bore and tube threads. you can also final bore your brake exit in this setup and ensure perfect alignment and run a smaller exit bore.

on a bolt gun you will be hard pressed to get the temperature of a suppressor to 600-700 deg which will keep the aluminum in the threshold of its strength range.

My next form 1 will be made from all 7075 aluminum except for the first baffle , I plan to use a commercial threaded brake/mount from either TBAC or Griffin. I'm gonna run it on an 18" AR-10 and see how many rounds it take to get it to 700 deg and try to keep it at an elevated temperature each time I shoot so I can guage the strength and erosion of the aluminum.

That's just my 2 cents

Re: 308 design critique

Posted: Fri Mar 25, 2016 5:58 am

by Samson1044

silencer_kid wrote:CMV wrote:

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

what about hard chrome?

Hard chrome would be a great coating for baffles , it greatly increases the barrel life on the M249 SAW.

Its not cheap , Melonite treating is another option i've thought about for baffles as it greatly increases the surface hardness and doesn't add anything to the dimentions of the part.

Re: 308 design critique

Posted: Fri Mar 25, 2016 8:36 am

by propeine

Samson1044 wrote:silencer_kid wrote:CMV wrote:

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

what about hard chrome?

Hard chrome would be a great coating for baffles , it greatly increases the barrel life on the M249 SAW.

Its not cheap , Melonite treating is another option i've thought about for baffles as it greatly increases the surface hardness and doesn't add anything to the dimentions of the part.

Any idea if H&M Nitriding has paid their SOT? I like those guys but never thought to ask them that.

Re: 308 design critique

Posted: Fri Mar 25, 2016 10:15 am

by NChobbymachining

CMV wrote:

Its worth a shot. Ill coat the 7 baffles after the blast baffle and see how it holds up. Ill order some 17-4 and use that for the blast baffle.

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

I figured it would be but I didn't see any harm in giving it a try. If I have uncoated 303 for the baffles, how much trouble will I have keeping it from corroding?

Re: 308 design critique

Posted: Fri Mar 25, 2016 10:26 am

by NChobbymachining

Samson1044 wrote:using 316 SS (even 304) as your blast baffle material would work fine and I doubt that you would ever wear it out unless you spend as much shooting as you do on your house note or unless you are running it full auto all the time. 17-4 is surely stronger that 316 but unless you have it on hand I wouldn't bother.

By using Grade 9 titanium tube and grade 5 for your end caps you would drop a lot of weight , you could even use 7075 aluminum for you caps and save more weight , use a brake style adapter and that would save even more wear on the blast baffle.

Like this

http://www.griffinarmament.com/Griffin- ... -p/tmm.htm

if you made the first 3 baffles out of out of SS and the rest from 7075 you would still get thousands and thousands of rounds out of it before you started to even see any wear on the aluminum baffles and after a couple years and 4,000-5,000 rounds if they were worn you could just replace them (assuming you are not in the US because that would be against the law especially if you went around telling people about it

)

Fabricate your spacer as part of your cone , this will help with strength if you went with aluminum and help with tolerance stacking and any possible bore misalignment

If you decide to make your rear cap from steel then you can mill or cut the meat from between the thread root of the threads to drop some weight , and even make a brake into it which is not that hard on a mill with an indexing head. for threaded caps I prefer to cut my female barrel threads first then make a male stub piece , thread it on in the chuck and then thread the male tube threads , this will ensure perfect alignment between the bore and tube threads. you can also final bore your brake exit in this setup and ensure perfect alignment and run a smaller exit bore.

on a bolt gun you will be hard pressed to get the temperature of a suppressor to 600-700 deg which will keep the aluminum in the threshold of its strength range.

My next form 1 will be made from all 7075 aluminum except for the first baffle , I plan to use a commercial threaded brake/mount from either TBAC or Griffin. I'm gonna run it on an 18" AR-10 and see how many rounds it take to get it to 700 deg and try to keep it at an elevated temperature each time I shoot so I can guage the strength and erosion of the aluminum.

That's just my 2 cents

The can will probably see about 1000 rds of 308, 3000 rds of 300blk, some super some subs, and maybe several hundred to a few thousand 223 every year. I am in the US so I would like everything to last as long as possible. However, if everything gets worn out on the inside, I can send it to an 07/02 and have them destroy the baffles and make me some new ones.

I have modeled it up using Gr 9 ti for the tube and spacers and that dropped several oz, but I don't think Gr 9 will hold up to the supersonic 300 blk. The Gr 5 is more than I am able to spend at the moment.

Do you think 7075 will hold up well against the 300 blk supers? I estimate the can will see around 4500 rds/year so that 4000-5000 rd estimate won't work for me.

Using 2024 for spacers, switching to cones instead of stepped baffles, and lightening up end caps and mounts has gotten it down to 17oz. That design is basically identical to another I have seen on here, I think it was CMV who made that one. Ti got it down to 12.5 oz. Making the last 5 baffles 7075 would probably get it under 10 oz...

I have the ability to make a brake similar to the one you posted. I modeled one up based on the design by Practical Renessaince on YouTube and I was considering that. I just read that for precision work, the direct thread was better.

Re: 308 design critique

Posted: Fri Mar 25, 2016 10:32 am

by NChobbymachining

silencer_kid wrote:CMV wrote:

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

what about hard chrome?

I have no problem getting them hard chromed. What would be the logistics of that? Would I need to machine them undersized to account for the added thickness? Right now I plan to make the baffles .005 smaller in diameter than the tube for a slip fit.

Also, how would it work sending suppressor parts out for work? I assume it has to be to an 07/02. Does it have to be in person or can it be shipped? I wasn't planning on outsourcing any of the work so I haven't researched that part extensively.

Re: 308 design critique

Posted: Fri Mar 25, 2016 11:44 am

by Samson1044

the titanium will handle ALOT more than what the 300 Blackout can throw at it unless you are running full auto or a super short barrel.

The Griffen Sportsman is rated to 300 min mag and is made from all 7050.

http://www.griffinarmament.com/Sportsma ... astm30.htm

Re: 308 design critique

Posted: Fri Mar 25, 2016 11:57 am

by NChobbymachining

Samson1044 wrote:the titanium will handle ALOT more than what the 300 Blackout can throw at it unless you are running full auto or a super short barrel.

The Griffen Sportsman is rated to 300 min mag and is made from all 7050.

http://www.griffinarmament.com/Sportsma ... astm30.htm

It is a 10.5 inch barrel, and its not a full auto (I wish...) It will usually see 20-30 rounds in 10-15 seconds followed by a few minutes then repeat for 150-200 rounds in about 30 minutes. If it ends up being light enough, it will see the same use on a 16 inch .223.

I would love to go titanium, but I know the tube is the only part I can't get replaced if it fails, so I want to make sure I get that right.

Re: 308 design critique

Posted: Fri Mar 25, 2016 6:15 pm

by CMV

NChobbymachining wrote:CMV wrote:

Its worth a shot. Ill coat the 7 baffles after the blast baffle and see how it holds up. Ill order some 17-4 and use that for the blast baffle.

Cerakote on the internals is is pointless. It's a great finish for the outside, but will not survive on the internals. I did my 10/22 integral monocore in Cerakote and even just rimfire quickly stripped it inside the chambers.

I figured it would be but I didn't see any harm in giving it a try. If I have uncoated 303 for the baffles, how much trouble will I have keeping it from corroding?

Not much. Periodic cleaning, keep dry. Less than a typical firearm. I wasn't trying to scare you off 303, just pointing out that it does corrode faster/worse/more easily than many other common alloys of stainless. If you've already bought it, by all means use it. Just pointing it out really. I think a lot of hobbyists - esp ones who haven't worked in metal fab or machining - just assume stainless = 0 corrosion. You get condensation in your suppressor from the temp & environment changes they see in normal use. I have one that the bulk of the material is chromemoly, but with a little care & common sense is just fine.

Re: 308 design critique

Posted: Wed Mar 30, 2016 10:39 pm

by NChobbymachining

My Form 1 was approved today. Looks like I need to get back to work on this design. Unless cone baffles won't suppress a 308 well, I think I will use those.

For materials I have decided to go with 316 stainless for the tube as I have some now I can use and I don't want to worry about titanium failing if I run it too hard.

Blast baffle will be 17-4 and .080 thick.

Remaining baffles will be 303 stainless and .060 thick.

The tube will be threaded on both ends and 7.6" long.

I have not decided on brake mount vs direct thread. For simplicity I would think direct thread but for versatility I would think brake mount. Ill work the tube and baffles first so I have more time to decide. Also, any input on spacing would be much appreciated.

I mostly see pictures of completed builds here. If anyone is interested, I will take a bunch of pictures of the machining process and the set ups I use as well as the finished product. Not so much of a how to, more of a "How I did it".

Re: 308 design critique

Posted: Wed Mar 30, 2016 10:56 pm

by fishman

NChobbymachining wrote:If anyone is interested, I will take a bunch of pictures of the machining process and the set ups I use as well as the finished product

those are always appreciated

Re: 308 design critique

Posted: Tue Apr 05, 2016 12:32 pm

by NChobbymachining

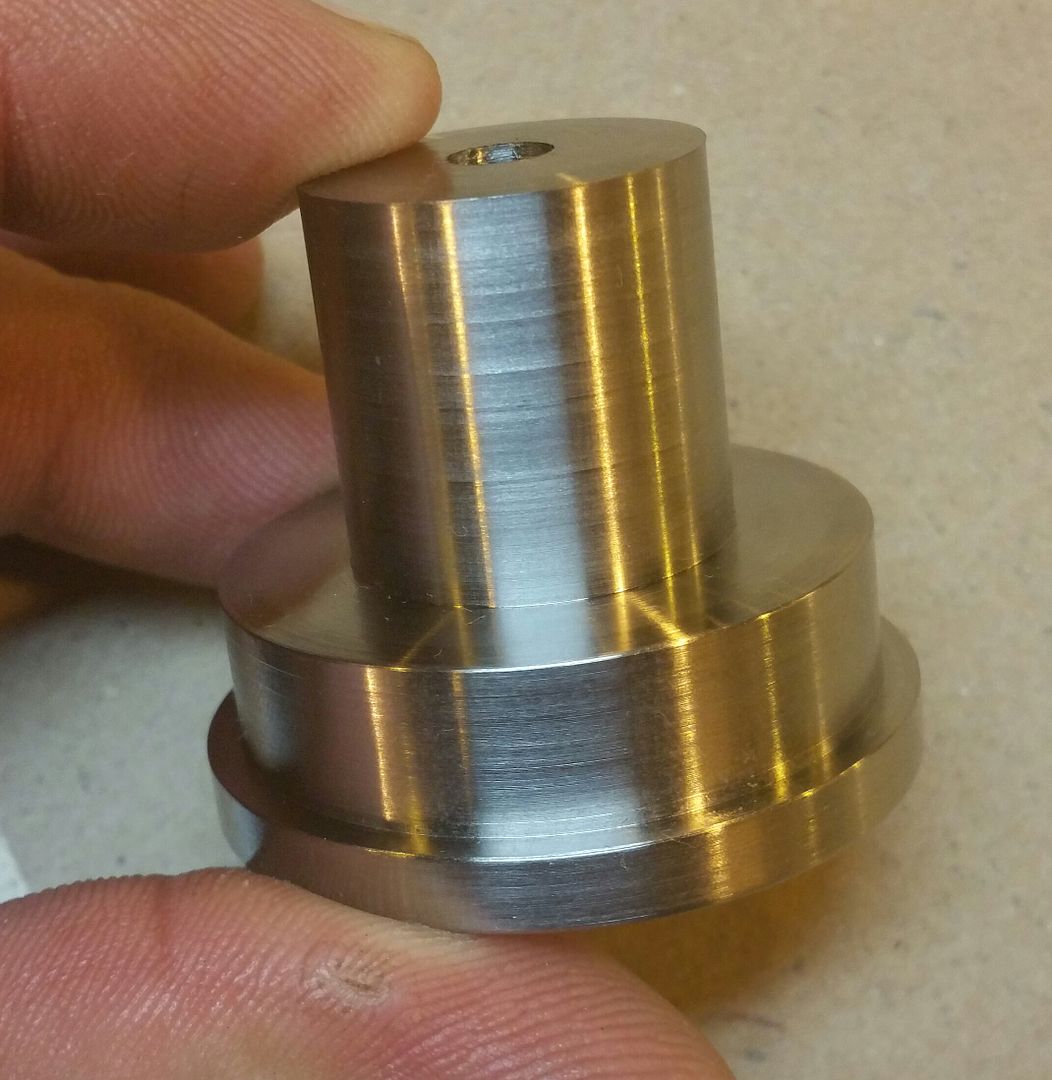

I am working on the design and getting ready to start initial machining.

If I have a mount for direct thread and one that mounts on the brake, would that be considered an adapter or extra parts in the eye of the law?

Re: 308 design critique

Posted: Wed Apr 06, 2016 12:24 pm

by NChobbymachining

I have come up with a new design and I am not entirely pleased with it. I do like the idea of a brake mount for the can, but that added 6 oz to the weight in just the cap and the brake. I also wasn't entirely sure how the brake should interact with the first baffles. The way I have it now, the first port vents into the blast chamber and the second port opens beyond the first chambers. Both the first and second cone had to be modified. The weight of this one with a direct thread mount was 17.5 oz. With the brake mount it is 23.5 oz.

Re: 308 design critique

Posted: Wed Apr 06, 2016 2:17 pm

by fishman

does the brake screw onto the barrel then the can onto the brake? or is the brake completely internal to the can? if the can screws onto the brake then the brake isn't considered a silencer part and can be modified and replaced whenever you want.

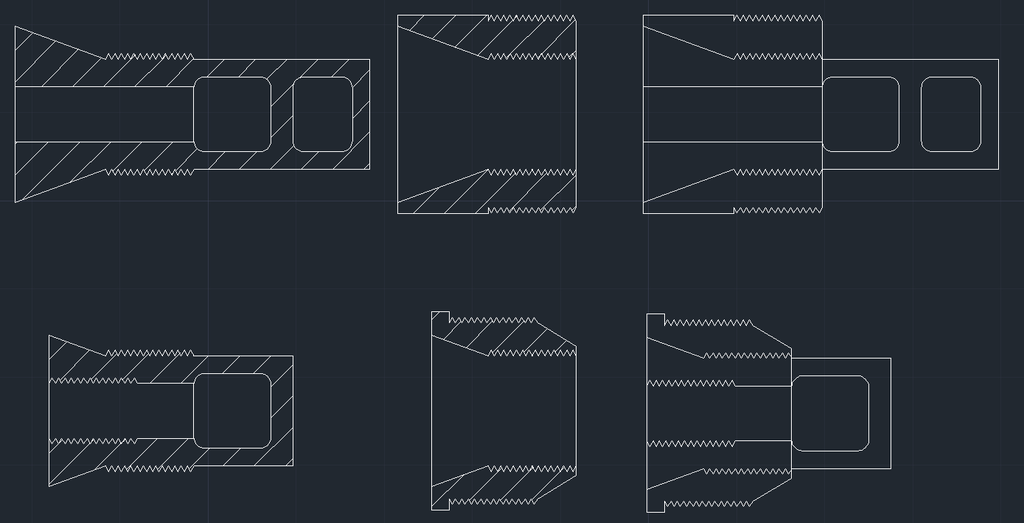

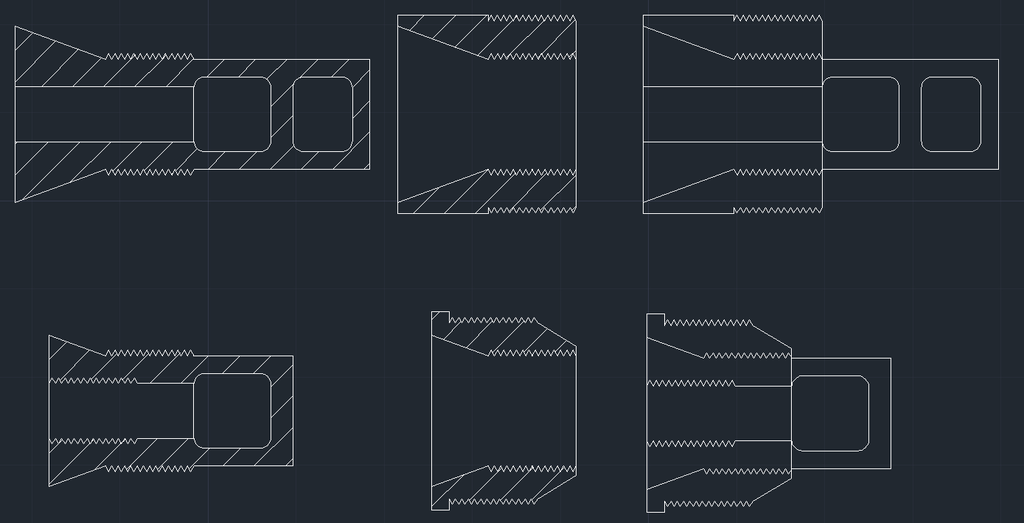

also, can you do a cross sectional view for us? it would be more helpful. what cad software are you using?

Re: 308 design critique

Posted: Wed Apr 06, 2016 3:34 pm

by NChobbymachining

fishman wrote:does the brake screw onto the barrel then the can onto the brake? or is the brake completely internal to the can? if the can screws onto the brake then the brake isn't considered a silencer part and can be modified and replaced whenever you want.

also, can you do a cross sectional view for us? it would be more helpful. what cad software are you using?

The brake threads onto the barrel and the can threads onto the brake. I was asking about having 2 end caps for the can but it looks like thats a no go.

I am using autocad. Ill cut it in half and post in about an hour when I get back to my computer.

Re: 308 design critique

Posted: Wed Apr 06, 2016 3:48 pm

by crazyelece

You can't have 2 endcaps (ie an extra as only 1 is used at a time) but you can have 1 endcap with 2 different adapters that thread into it.

Like a multimount. One adapter can be for direct thread, and one can be for threading onto a break.

Re: 308 design critique

Posted: Wed Apr 06, 2016 4:46 pm

by NChobbymachining

Here is a cross section. I changed colors because everything sort of blended together without the coloring.

Re: 308 design critique

Posted: Wed Apr 06, 2016 5:41 pm

by fishman

I use autocad every day at work yet ive never once used the 3d features. i didnt even recognize that was autocad.

regarding the brake, if it were me, i'd cut the brake down to only one chamber. that is, unless you want better performance out of the brake while the suppressor isnt mounted. it doesnt look like having the brake that long is going to help anything while the suppressor is mounted. shortening it would make it lighter. also if you make the round hole in the brake a rectangular or square hole, it will brake more effectively and cut weight.

to further cut weight, i would make the rear endcap much thinner, and therefore make the brake shorter

Re: 308 design critique

Posted: Wed Apr 06, 2016 6:07 pm

by fishman

a design more like the bottom one will cut weight, and give you a shorter overall length