monocore machining?

- mattman0o0o

- Member

- Posts: 41

- Joined: Mon Dec 06, 2010 5:50 pm

- Location: Kansas

monocore machining?

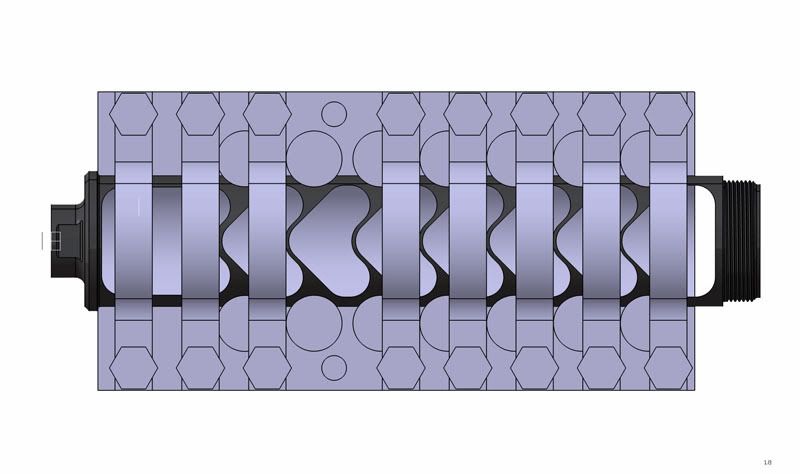

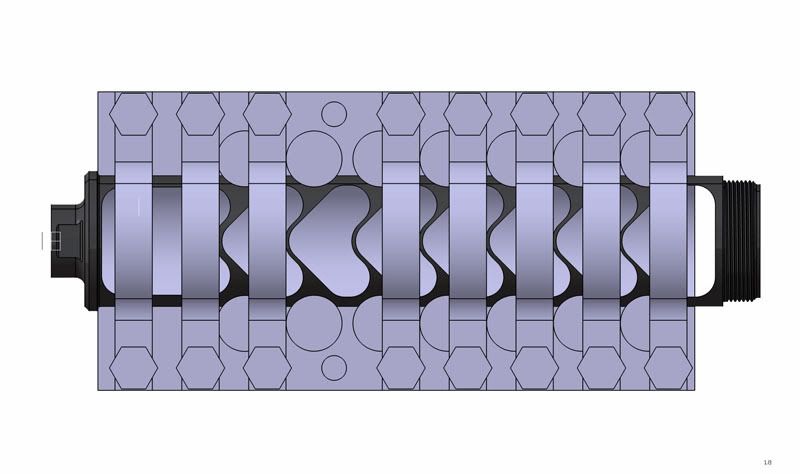

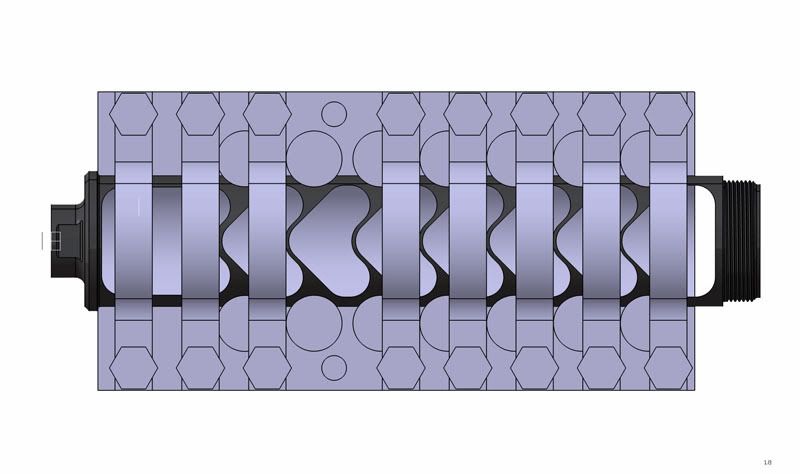

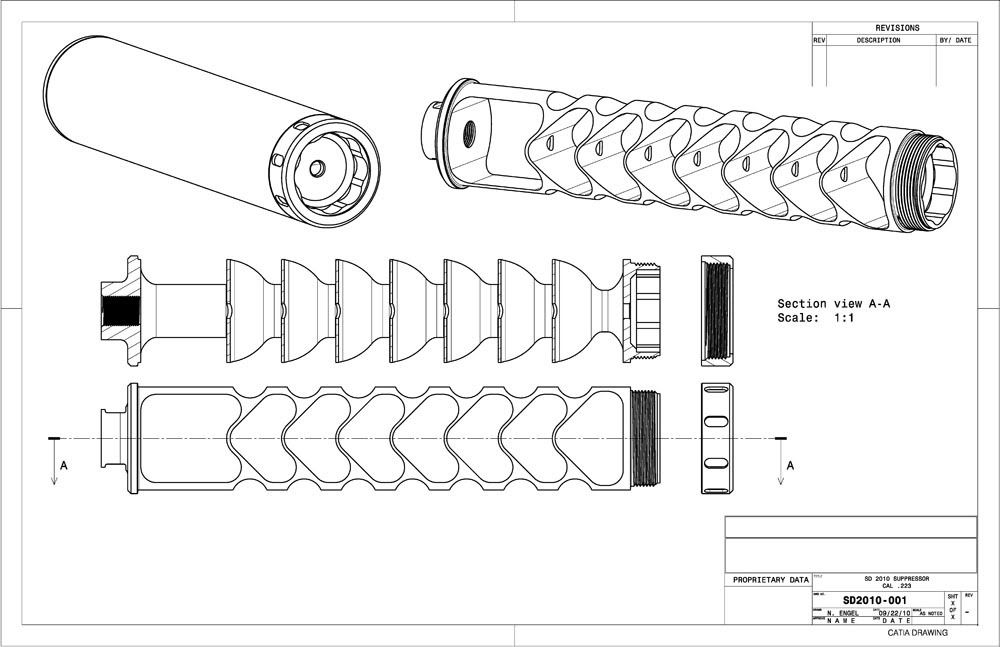

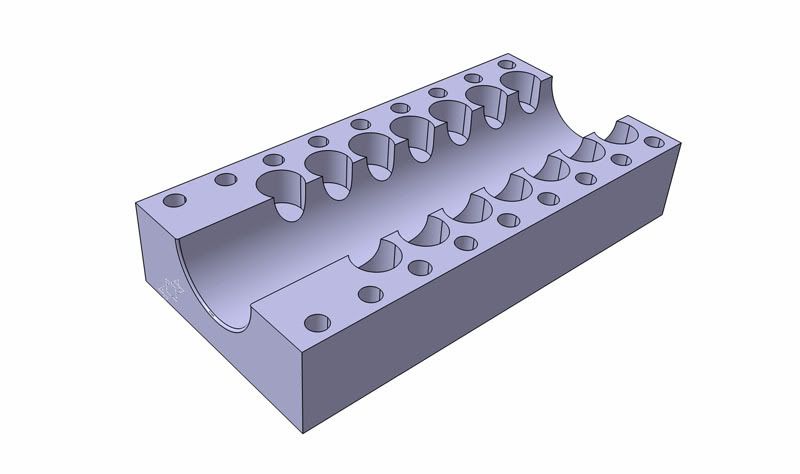

When machining a monocore is something as robust as this needed? Or would simply clamping the bar stock between some V blocks suffice?

.22 form 1 - http://youtu.be/grDBBcMjacI

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

Re: monocore machining?

Depends on a lot of factors. Aluminum? Titanium? Is the bar round or square during this stage? How heavy of a cut are you making?

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

- mattman0o0o

- Member

- Posts: 41

- Joined: Mon Dec 06, 2010 5:50 pm

- Location: Kansas

Re: monocore machining?

Call it turned to diameter already and SS.

.22 form 1 - http://youtu.be/grDBBcMjacI

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

Re: monocore machining?

The best way to know would be to try it, but I'd imagine you wouldn't need a fancy figure if you kept your cuts light.mattman0o0o wrote:Call it turned to diameter already and SS.

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

Re: monocore machining?

What flavor of stainless steel?mattman0o0o wrote:Call it turned to diameter already and SS.

Re: monocore machining?

The legion of possible designs have their own

set ups. Googling 'monocore silencer' you get

an overview of various topologies.

The most basic of course in the primitively efficient

Stechkin silencer with its few tilted disks.

Instructive video:

<< https://www.youtube.com/watch?v=rDHkTvv4RAE >>

Third Video shows milling holes:

<< https://www.youtube.com/watch?v=Hyc37aHNZ7k >>

Look forward to your presentation when done.

Best.

set ups. Googling 'monocore silencer' you get

an overview of various topologies.

The most basic of course in the primitively efficient

Stechkin silencer with its few tilted disks.

Instructive video:

<< https://www.youtube.com/watch?v=rDHkTvv4RAE >>

Third Video shows milling holes:

<< https://www.youtube.com/watch?v=Hyc37aHNZ7k >>

Look forward to your presentation when done.

Best.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: monocore machining?

Why not mill from square bar and turn between centers?

Just use the mill vise and forgo the jig.

What are the circles, just inside the row of bolts?

Just use the mill vise and forgo the jig.

What are the circles, just inside the row of bolts?

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: monocore machining?

So darn clever!T-Rex wrote:Why not mill from square bar and turn between centers?

Just use the mill vise and forgo the jig.

What are the circles, just inside the row of bolts?

Best

- mattman0o0o

- Member

- Posts: 41

- Joined: Mon Dec 06, 2010 5:50 pm

- Location: Kansas

Re: monocore machining?

would turning the square to a round with all those pockets work? Never tried that before.

.22 form 1 - http://youtu.be/grDBBcMjacI

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: monocore machining?

You're right to be concerned as you will have an interrupted for the majority of turning.

Before you remove it from the vise, use a round-over bit (in the mill) to remove the corners. You don't have to be perfect, just remove material.

Use a hefty, square negative, basic shaped insert.

Slow turning and feed rates.

What extra time the slow turning would require will be gained w/ not having to make a jig.

You could, also, use a 12" piece of square and turn the center portion (between centers) down to finished OD. Use the square ends to fix in vise.

What are the circles, just inside the row of bolts?

Before you remove it from the vise, use a round-over bit (in the mill) to remove the corners. You don't have to be perfect, just remove material.

Use a hefty, square negative, basic shaped insert.

Slow turning and feed rates.

What extra time the slow turning would require will be gained w/ not having to make a jig.

You could, also, use a 12" piece of square and turn the center portion (between centers) down to finished OD. Use the square ends to fix in vise.

What are the circles, just inside the row of bolts?

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

- mattman0o0o

- Member

- Posts: 41

- Joined: Mon Dec 06, 2010 5:50 pm

- Location: Kansas

Re: monocore machining?

Here's the page I found that jig on, not sure which circles you're asking about, this page explains the guys whole set up.

http://www.ar15.com/forums/t_6_20/35267 ... tml&page=1

http://www.ar15.com/forums/t_6_20/35267 ... tml&page=1

.22 form 1 - http://youtu.be/grDBBcMjacI

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

.22 form 1 build thread - http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79544

- Fulliautomatix

- Silent But Deadly

- Posts: 253

- Joined: Sun Sep 18, 2011 7:46 pm

Re: monocore machining?

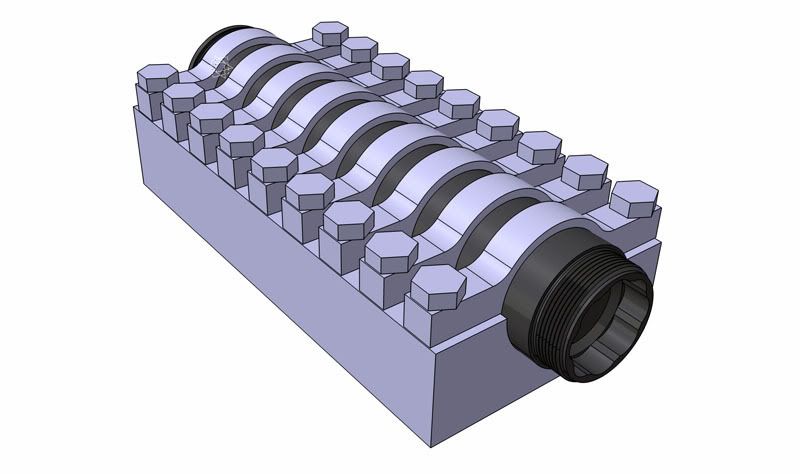

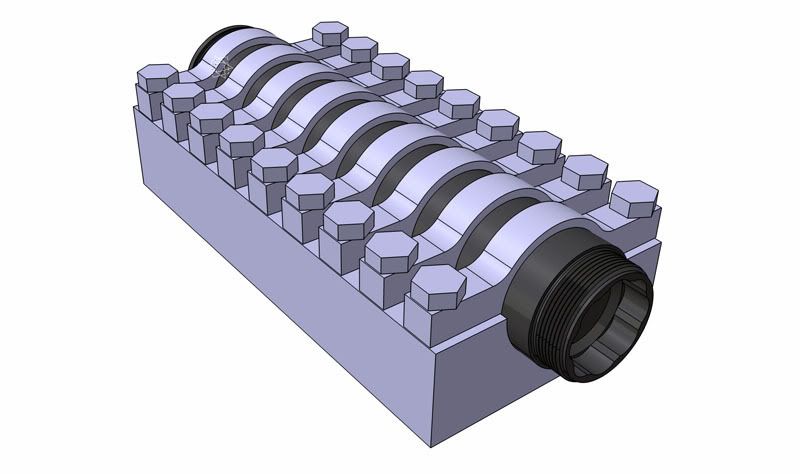

Those holes are in the jig to allow machining of the scallops tangential to the OD of the monocore. See the isometric view of the monocore, and of the jig below.T-Rex wrote: What are the circles, just inside the row of bolts?

Speak softly, and carry a big stick.

- Fulliautomatix

- Silent But Deadly

- Posts: 253

- Joined: Sun Sep 18, 2011 7:46 pm

Re: monocore machining?

Seems like it is overly complicated and will add significantly to the time to manufacture each monocore. Very labor intensive to access that jig and unbolt/rebolt each one of those caps as you machine each cavity.

Last edited by Fulliautomatix on Tue Dec 06, 2016 7:37 am, edited 1 time in total.

Speak softly, and carry a big stick.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: monocore machining?

I thought as such. I just don't like to assume.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: monocore machining?

You guys are over thinking this whole thing, just mill some soft jaws with your cores outside diameter and clamp it with about 10ft-lbs of torque.