New Baffle Design

New Baffle Design

Noob here, but long time lurker.

Have shop with mill, lathe, shaper, universal tool grinder, and whatnots.

Two previous Form 1 .22 rimfire builds, waiting on 3rd for Blackout build on 10.5" AR SBR.

Thinking outside the box of all the hundreds of pages of comments and designs on this thread, so I thought I might throw my ring into the hat on a baffle design not yet seen here (to my knowledge).

Don't worry, I can take a beating.

So far I've not yet been able to create a drawing which makes this easier to understand, but from a machining center point of view it's quite simple, sort of.

Start with a 60 degree cone baffle of whatever skirt or spacer length TBD, then instead of conventionally clipping or half clipping the cone, center an endmill over the bore hole wall. Power the quill down while holding the baffle in a standard or powered rotary table, rotating about 340 degrees depending on diameter of the tooling. Total quill down travel would be somewhere between 0.100 and 0.200 inches.

That ought to play havoc with transitional gasses. Would like to hear from the Pro's if this is a dead end.

Sort of like starting on top of a volcano crater and bulldozing a road downward around the rim. Edit: Not a spiral stepped cone.

Have shop with mill, lathe, shaper, universal tool grinder, and whatnots.

Two previous Form 1 .22 rimfire builds, waiting on 3rd for Blackout build on 10.5" AR SBR.

Thinking outside the box of all the hundreds of pages of comments and designs on this thread, so I thought I might throw my ring into the hat on a baffle design not yet seen here (to my knowledge).

Don't worry, I can take a beating.

So far I've not yet been able to create a drawing which makes this easier to understand, but from a machining center point of view it's quite simple, sort of.

Start with a 60 degree cone baffle of whatever skirt or spacer length TBD, then instead of conventionally clipping or half clipping the cone, center an endmill over the bore hole wall. Power the quill down while holding the baffle in a standard or powered rotary table, rotating about 340 degrees depending on diameter of the tooling. Total quill down travel would be somewhere between 0.100 and 0.200 inches.

That ought to play havoc with transitional gasses. Would like to hear from the Pro's if this is a dead end.

Sort of like starting on top of a volcano crater and bulldozing a road downward around the rim. Edit: Not a spiral stepped cone.

-

Hatchetjoe

- Silent But Deadly

- Posts: 185

- Joined: Mon Jul 07, 2008 6:12 pm

Re: New Baffle Design

I can't wait to see this drawn up.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: New Baffle Design

Would itbe easier to just make one? Sans interior cone profile and bore drill, of course.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

-

a_canadian

- Silent But Deadly

- Posts: 1204

- Joined: Fri Oct 11, 2013 3:09 pm

Re: New Baffle Design

If I'm understanding your description correctly it seems the cone wall would have to be rather a lot thicker than normally to allow for such a spiralling cut. Sounds like you'd lose as much in air volume as you might gain in flow disruption.

Re: New Baffle Design

Do you mean a shallow groove to shape the rear surface of the cone, or one deep enough to cut through to the front face and serve as a vent?

-

BinaryAndy

- Silent Operator

- Posts: 99

- Joined: Tue May 06, 2014 4:05 pm

- Location: Lancaster County, PA

Re: New Baffle Design

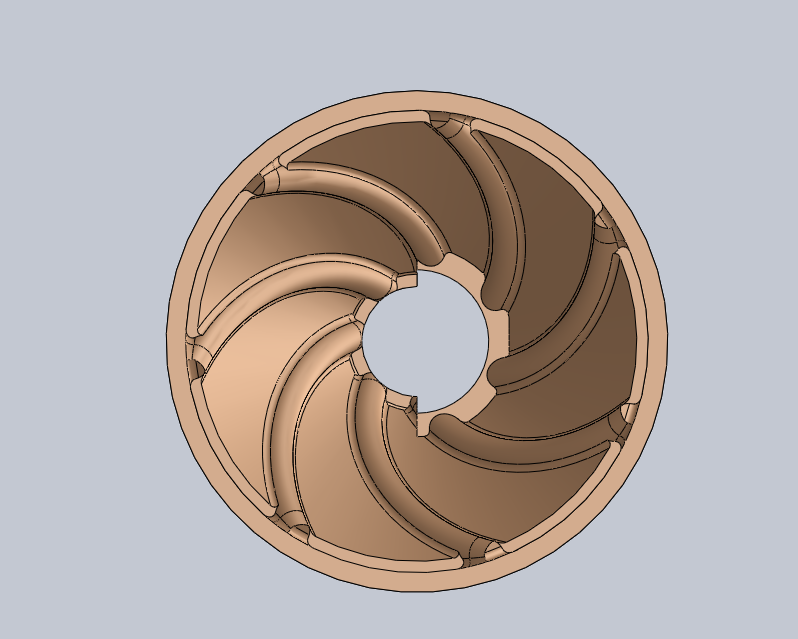

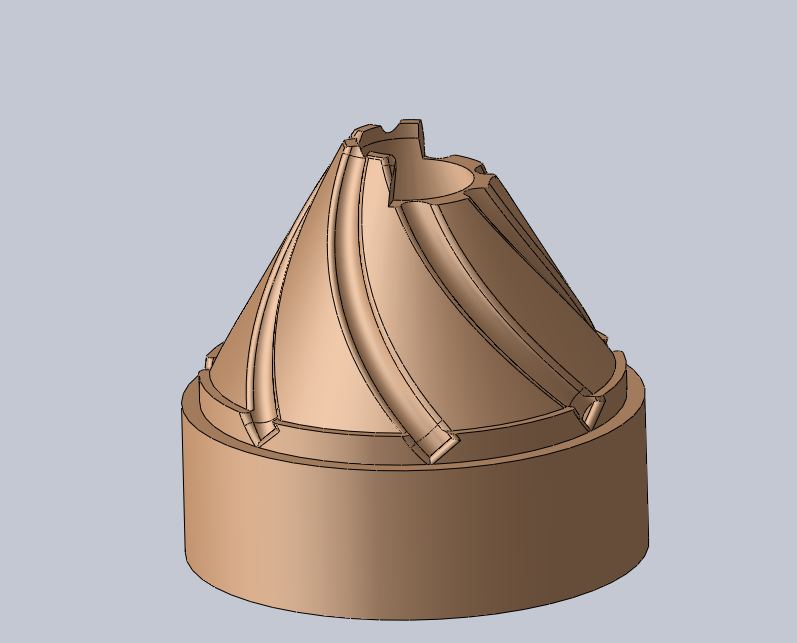

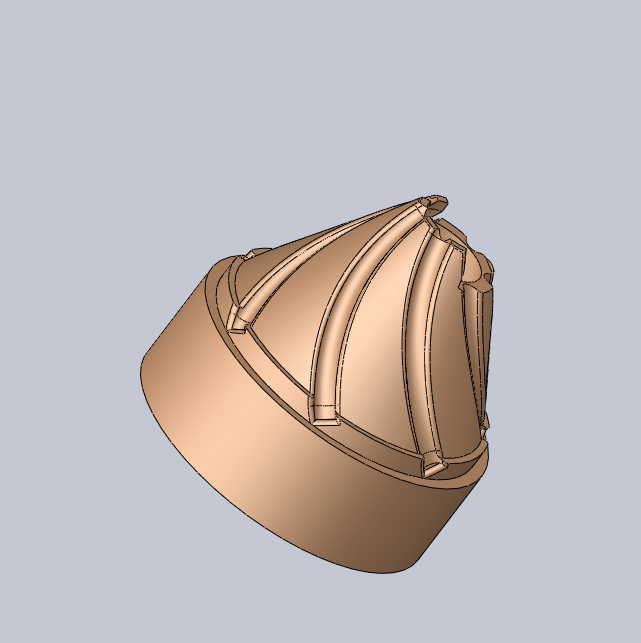

I think I get it. Take a normal cone, held pointy end up in a mill. Use a small end mill to cut a partial helix, by moving the center of the end mill in a partial circle around the perimeter of the baffle's bore in the XY plane, while simultaneously moving down in the Z axis. The result would be a normal cone baffle, with the front edge cut to a shape kind of like one coil of a spring.

Do I have that right?

Do I have that right?

Andy Gamble

Binary Arms

07/02

Binary Arms

07/02

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: New Baffle Design

This is what I had envisioned.BinaryAndy wrote:I think I get it. Take a normal cone, held pointy end up in a mill. Use a small end mill to cut a partial helix, by moving the center of the end mill in a partial circle around the perimeter of the baffle's bore in the XY plane, while simultaneously moving down in the Z axis. The result would be a normal cone baffle, with the front edge cut to a shape kind of like one coil of a spring.

Do I have that right?

I'm sure someone has tried it. Doesn't mean it won't work. Just maybe the effect wasn't great enough to quantify a new process. The M42K baffles are probably the most produced cone with a distinctive feature. (Just a guess)

From doing projects requiring gas nozzles, air/Chem mixing, etc, I'd venture to say that an impulse flow will not have the time or force required to hold a destabilizing event, especially not the feature described.

Look at the OSS design. The amount of time and effort it took to separate, channel and disperse the flow, an R&D nightmare.

However, ideas like yours shouldn't be dispensed due solely to simplicity.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: New Baffle Design

I'm sure I've seen this feature on a commercial can as well as a form 1 in this very forum. Thunderbeast maybe? Where is the baffle pics thread?!T-Rex wrote:This is what I had envisioned.BinaryAndy wrote:I think I get it. Take a normal cone, held pointy end up in a mill. Use a small end mill to cut a partial helix, by moving the center of the end mill in a partial circle around the perimeter of the baffle's bore in the XY plane, while simultaneously moving down in the Z axis. The result would be a normal cone baffle, with the front edge cut to a shape kind of like one coil of a spring.

Do I have that right?

I'm sure someone has tried it. Doesn't mean it won't work. Just maybe the effect wasn't great enough to quantify a new process. The M42K baffles are probably the most produced cone with a distinctive feature. (Just a guess)

From doing projects requiring gas nozzles, air/Chem mixing, etc, I'd venture to say that an impulse flow will not have the time or force required to hold a destabilizing event, especially not the feature described.

Look at the OSS design. The amount of time and effort it took to separate, channel and disperse the flow, an R&D nightmare.

However, ideas like yours shouldn't be dispensed due solely to simplicity.

Its all diminishing returns seems to be the problem. 70% more effort for 3% more gains.

-

BinaryAndy

- Silent Operator

- Posts: 99

- Joined: Tue May 06, 2014 4:05 pm

- Location: Lancaster County, PA

Re: New Baffle Design

It's an easy enough cut to make. I don't see any reason it should work any better or worse than any other asymmetrical clipping geometry, although some clipping geometries do in fact work better than others and in most cases I have no idea why and could not have predicted the results. So I'm sure it will work, but in my opinion the current level of understanding of the physics of cone baffles is insufficient to predict whether it will work better or worse than many other things that work.

Andy Gamble

Binary Arms

07/02

Binary Arms

07/02

Re: New Baffle Design

Only 1 way to know for sure is to try it. Personally, I would like to see how it does.

I even thought about doing a monocore, with baffles shaped kind of like this that were ported from the expansion chamber to direct as much gas away from the bore as possible. Would be pretty simple with a lathe and mill:

I even thought about doing a monocore, with baffles shaped kind of like this that were ported from the expansion chamber to direct as much gas away from the bore as possible. Would be pretty simple with a lathe and mill:

I don't care what your chart says

Re: New Baffle Design

Is that one of the 3D printed ones from New Zealand?John A. wrote:Only 1 way to know for sure is to try it. Personally, I would like to see how it does.

I even thought about doing a monocore, with baffles shaped kind of like this that were ported from the expansion chamber to direct as much gas away from the bore as possible. Would be pretty simple with a lathe and mill:

Also I found the TBAC baffles

viewtopic.php?f=10&t=116272&hilit=spiral

Spiral Form 1 Baffles

viewtopic.php?f=10&t=109557&hilit=spiral

Re: New Baffle Design

BinaryAndy wrote:

I think I get it. Take a normal cone, held pointy end up in a mill. Use a small end mill to cut a partial helix, by moving the center of the end mill in a partial circle around the perimeter of the baffle's bore in the XY plane, while simultaneously moving down in the Z axis. The result would be a normal cone baffle, with the front edge cut to a shape kind of like one coil of a spring.

Do I have that right?

@BinaryAndy...

Well described.

Sorry for late reply but gone for week. I may do a test piece with a partial bore hole and post pic for review, which will keep me off felons list until stamp arrives.

I think I get it. Take a normal cone, held pointy end up in a mill. Use a small end mill to cut a partial helix, by moving the center of the end mill in a partial circle around the perimeter of the baffle's bore in the XY plane, while simultaneously moving down in the Z axis. The result would be a normal cone baffle, with the front edge cut to a shape kind of like one coil of a spring.

Do I have that right?

@BinaryAndy...

Well described.

Sorry for late reply but gone for week. I may do a test piece with a partial bore hole and post pic for review, which will keep me off felons list until stamp arrives.

Re: New Baffle Design

When I first read your post I imagined you just did not want to bother with designing your suppressor on paper. The second time I read it along with other replies I now understand how your idea may be difficult to model with lower end 3D design software such as SoldWorks.

I've been using Unigraphics/NX for 30 plus years and recent was forced to use SolidWorks 2017. Though many may think it's great software it really is limiting as to how you can design parts. It software for someone designing prismatic parts. Not for doing advance surface modeling. To do what you describe could probably be done in SolidWorks, but it would not be easy.

NX started out being developed by the aerospace industry way back in the 70's. Advanced modeling techniques have always been what the software is all about. Along with machine programming modules to do just about any kind of metal removal.

I would like to see your design soon.

I've been using Unigraphics/NX for 30 plus years and recent was forced to use SolidWorks 2017. Though many may think it's great software it really is limiting as to how you can design parts. It software for someone designing prismatic parts. Not for doing advance surface modeling. To do what you describe could probably be done in SolidWorks, but it would not be easy.

NX started out being developed by the aerospace industry way back in the 70's. Advanced modeling techniques have always been what the software is all about. Along with machine programming modules to do just about any kind of metal removal.

I would like to see your design soon.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: New Baffle Design

Took about 6 minutes. That included: opening the program, starting a new project, and uploading it to the web. I did 3 cuts, because I had extra timeDogstar wrote: To do what you describe could probably be done in SolidWorks, but it would not be easy.

I know NX is steps above SW, but come-on it's 2017, you really thought a conical helix would be difficult?

espirit wrote:BinaryAndy wrote:

Take a normal cone, held pointy end up in a mill. Use a small end mill to cut a partial helix, by moving the center of the end mill in a partial circle around the perimeter of the baffle's bore in the XY plane, while simultaneously moving down in the Z axis. The result would be a normal cone baffle, with the front edge cut to a shape kind of like one coil of a spring.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: New Baffle Design

With 5-axis, might as well make it a radial cone. Post above shows it's already been done.

BTW - SolidWorks bites.

BTW - SolidWorks bites.

Last edited by espirit on Thu Jun 29, 2017 9:24 pm, edited 1 time in total.

Re: New Baffle Design

Ok, I'm baffled out and inspired by the OSS design.

For the tech gurus - How about moveable turbine(s) within the can to absorb energy and heat?

I can dream next-gen technology, can't I?

For the tech gurus - How about moveable turbine(s) within the can to absorb energy and heat?

I can dream next-gen technology, can't I?

-

Hannibalbarca

- Silent But Deadly

- Posts: 239

- Joined: Sat Dec 31, 2016 5:38 pm

Re: New Baffle Design

This isnt new. i saw this on grab cad a while back.

there really isnt anything new to be done for baffle designs only the materials used or perhaps some sort of exotic solution thats basically a turbine. not a turbine shape but a spinning turbine or perhaps some sort of super material that is able to absorb the gasses and has a high heat tolerance - a spongy material with very small particles and holes.

Re: New Baffle Design

Thinking static absorption of thermal and dynamic forces just won't do it.

Something about opposite reaction plays a key here.

Perhaps more consideration should be given to suppressed-only weapons design, tho' it seems we're headed that way.

Something about opposite reaction plays a key here.

Perhaps more consideration should be given to suppressed-only weapons design, tho' it seems we're headed that way.

Re: New Baffle Design

Ok, how do you counter the expanding gasses leaving the bore to make an opposite reaction?espirit wrote:Thinking static absorption of thermal and dynamic forces just won't do it.

Something about opposite reaction plays a key here.

Perhaps more consideration should be given to suppressed-only weapons design, tho' it seems we're headed that way.

I don't know the answer to that. But is a million dollar question.

I think at best, you would be served by harnessing the power and redirecting it to cause a different reaction (like water mills and hydro power plants), rather than an opposite one.

But again, that's way above my pay grade. Energy is supposedly infinite. But you can change it from one form of energy to another a lot easier than you can make it do the opposite of what it is already doing.

I don't care what your chart says

-

a_canadian

- Silent But Deadly

- Posts: 1204

- Joined: Fri Oct 11, 2013 3:09 pm

Re: New Baffle Design

A suppressor with attached bottle of liquid nitrogen, feeding into the whole body a second before the shot, might be able to sufficiently cool the expanding gases that a positive suppression efficiency was realised. Essentially an equal and opposite reaction in the form of cooling the heated gases. Of course this would also embrittle most baffle and tube materials, resulting in shattering of the device due to pressure. But with the right materials it could work. Can't say I'd want such a gizmo myself... sounds cumbersome.

Re: New Baffle Design

If HPA passes, I'm thinking of threading and putting tubing into each chamber so some of the gas will port outside of the silencer (away from the bore). The tubing will wrap around the external surface of the can to keep the surface footprint as small as possible, and the tubing will be shaped much like those pigtail gas tubes for AR's.

This will give more suppression more akin to how an integral acts, only a little different method achieving it.

Each tube will be reintroduced back into the expansion chamber at the rear endcap, which will add a lot of area of suppression over typical silencer length.

While in the tubing, could also theoretically run it through an external water cooling chamber, kind of like a bong. (Or so I have heard.)

But I would worry a little about steam explosions during full auto dumps if not specifically using antifreeze. Even without the water cooling chamber, would still increase the surface area of the expanding gas away from the bore and delayed release into the atmosphere.

And realistically, if you used the water cooled idea, could run through a picatinny rail mounted radiator via a hose and connector like how transmission coolers attach.

Yes, that idea is really far out there over conventional suppressors, but thinking outside of the box has always been one of my strong suits.

I am confident that my idea has never been publically shown before.

I call it, the John Can number 1.

And for an even shittier design, stay tuned for the John Can number 2.

This will give more suppression more akin to how an integral acts, only a little different method achieving it.

Each tube will be reintroduced back into the expansion chamber at the rear endcap, which will add a lot of area of suppression over typical silencer length.

While in the tubing, could also theoretically run it through an external water cooling chamber, kind of like a bong. (Or so I have heard.)

But I would worry a little about steam explosions during full auto dumps if not specifically using antifreeze. Even without the water cooling chamber, would still increase the surface area of the expanding gas away from the bore and delayed release into the atmosphere.

And realistically, if you used the water cooled idea, could run through a picatinny rail mounted radiator via a hose and connector like how transmission coolers attach.

Yes, that idea is really far out there over conventional suppressors, but thinking outside of the box has always been one of my strong suits.

I am confident that my idea has never been publically shown before.

I call it, the John Can number 1.

And for an even shittier design, stay tuned for the John Can number 2.

I don't care what your chart says

Re: New Baffle Design

Incorporating a couple of industrial strength camera like diaphragms could be revolutionary.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: New Baffle Design

not sure where you're going, but a silencer already does the opposite by containing the gases getting released from the bore. They're allowed to expand and cool in a controlling environment. Are you saying we should try to keep them pressurized or let them expand faster?espirit wrote: Something about opposite reaction

I see what you did thereJohn A. wrote:And for an even shittier design, stay tuned for the John Can number 2.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/