Page 1 of 1

45 k baffle critique

Posted: Fri Jan 06, 2017 7:36 am

by jarrodl

Re: 45 k baffle critique

Posted: Fri Jan 06, 2017 8:37 am

by vaeevictiss

i cant help you much as im just learning (and failing lol) on making k's myself but im slowly getting it. Luckily i have a buddy that owns a gun shop w/ a shooting booth and hes an 07/02 so i can do a lot of trial and error there.

What i was told by a member here thats been helping me, and what im guessing you will be told as well, is that the port on the cone into the coaxial space is too large. Cutting the holes tho im not quite sure how to avoid it. I use a mill of the same diameter of the bore for the face cut, then use a smaller diameter mill to make the cut into the cone from the backside. I line the center of the mill with the edge of the bore as i have seen on several diagrams. Somehow, im still taking too much off and making my hole on the cone too large.

If you dont know an 07/02 you are kinda screwed because at this point you are only allowed to remove metal and not add it. Also, removing the spacer to make a bigger blast chamber will only give you more FRP. you want to get that first baffle about 1/2" from the muzzle.

I suppose i could move the center of the mill closer to the center of the bore, but Ive not seen a single diagram that shows to do it that way. Im almost ready to just give up on it and buy some premade "radial" baffles from Stacks Unlimited...

http://i.imgur.com/h7O6GQX.jpg

they also make k baffles (and 60 degree cones)

http://i.imgur.com/5t1lPF9.jpg

Im just really hesitant to do so. One, because it comes out to a lot of money at $20 apiece and two, because i do like the feeling of making a can from scratch by myself. I have made two 60 degree cone cans myself for my rifles that outperform my friends mfg. cans...albeit mine are a little heavier...pros and cons lol.

Re: 45 k baffle critique

Posted: Fri Jan 06, 2017 8:59 am

by T-Rex

Here's a link to my 45cal build using K-baffles.

I agree w/ VV that your vent hole may be too large. You want to get the gas into the coaxial space, but you also want it to dwell there.

Also, it's not just about the size of your scoop and/or vent, but how they align to one another. The purpose of the scoop is to cross-jet the gas, causing it to enter the vented space, and cause an asymmetrical flow in the boreline. The path created by the bit, used to make the vent hole, may be allowing a portion of the gas to simply slip by.

Do you have a drawing you went by?

With a section down the axis?

Re: 45 k baffle critique

Posted: Fri Jan 06, 2017 9:42 am

by vaeevictiss

i also just noticed it looked like the center of your end mill was out past the edge of the bore by a little bit.

Re: 45 k baffle critique

Posted: Fri Jan 06, 2017 9:46 am

by jarrodl

T-Rex wrote:

Do you have a drawing you went by?

With a section down the axis?

Somewhere. Ill try to find it. I drew it a long time ago and just go around to machining the baffles lately.

Re: 45 k baffle critique

Posted: Fri Jan 06, 2017 11:18 am

by a_canadian

Replacing the middle baffle with a spacer slightly shorter than a K and adding another shorter spacer to create a slightly larger blast chamber might help. Other than that I'll jump on the bandwagon and agree that the waist port seems excessively large. Milling from the front, inside the cone, and starting in toward the bore center a bit more then nibbling a bit outward at a time will get you whatever size you stop at. Somewhere around 3/5ths of that size exit hole might be preferable.

Re: 45 k baffle critique

Posted: Fri Jan 06, 2017 12:54 pm

by jarrodl

I made these ports with a .5 ball mill. Half the bit in the bore, the other half cutting metal. I did it the same way on the backside. I though I read somewhere that half way was what it should be. I guess that wasn't right. It does make a large hole on the backside. Maybe a 3/8" bit would have been better.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 7:28 am

by jarrodl

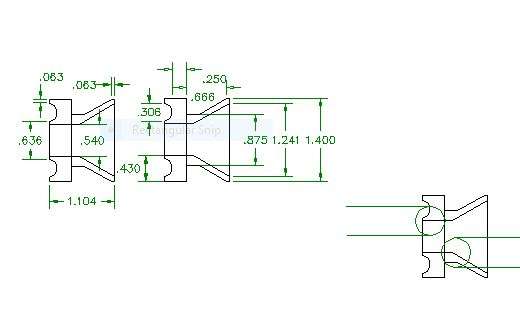

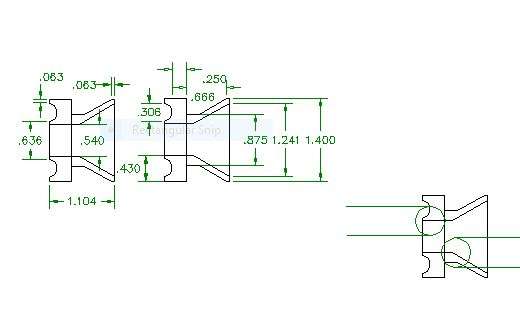

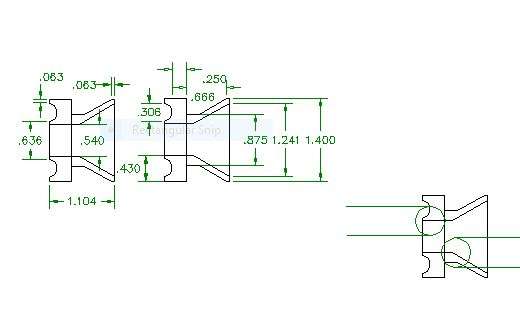

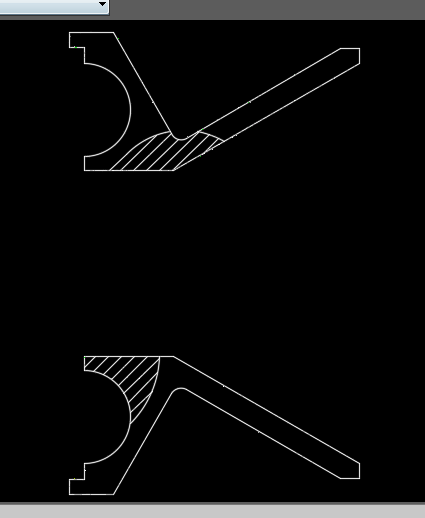

Here is the drawing I made it off of.

The green lines and circles on the bottom right

image represent where the ports were cut with a 1/2" ball mill.

It seems to me they should be lined up close enough for the cross jetting

to take place. I dont know.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 10:44 am

by fishman

jarrodl wrote:

Here is the drawing I made it off of.

The green lines and circles on the bottom right

image represent where the ports were cut with a 1/2" ball mill.

It seems to me they should be lined up close enough for the cross jetting

to take place. I dont know.

The endmill cut from the front should be deeper. There's very little overlap of the two endmill cuts. I think crossbore jetting is stunted with this design. Also, why Is the waist of the baffle so long?

Also, you should remove material from the front side of the rear face, increasing the volume of the space outside the baffle, while lightening that baffle.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 11:10 am

by mcrump

viewtopic.php?f=10&t=136572

The skirt to back of the face angle should be 90 degrees.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 11:25 am

by fishman

That's debatable, I can think of several effective k baffles that don't meet that criteria

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 11:44 am

by T-Rex

Here is a picture from AACs baffle patent. (pic is too large to embed)

The angle, from the skirt back to the face, is well passed 90*

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 12:47 pm

by jarrodl

fishman: The skirt ended up long like that because the drawing started out for 9mm. I had to get the skirt diameter larger to be able to bore a hole big enough for the 45. When I machined the actual baffle, it didnt turn our hardly as long.

Rekon moving the bit a little closer to the bore centerline and going a little deeper would help?

Does anyone have a drawing that shows where and what size scoops are good for 45 k's? I have another stamp and may just try to make some better. Only thing is, I dont want to ruin another set of k's.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 2:27 pm

by fishman

jarrodl wrote:fishman: The skirt ended up long like that because the drawing started out for 9mm. I had to get the skirt diameter larger to be able to bore a hole big enough for the 45. When I machined the actual baffle, it didnt turn our hardly as long.

Rekon moving the bit a little closer to the bore centerline and going a little deeper would help?

Does anyone have a drawing that shows where and what size scoops are good for 45 k's? I have another stamp and may just try to make some better. Only thing is, I dont want to ruin another set of k's.

Do you have a drawing of what you actually built? that'd be far more helpful

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 6:15 pm

by T-Rex

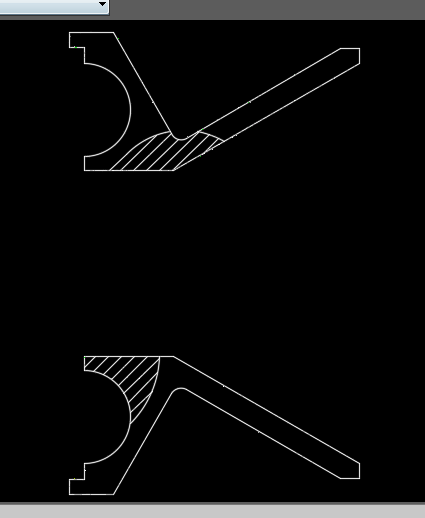

This is the design I used for my 45cal rifle, linked in the post above.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 6:26 pm

by a_canadian

T-Rex wrote:This is the design I used for my 45cal rifle, linked in the post above.

Now that waist vent is looking a bit small. Could you share a picture of a completed K showing that hole? Probably just the side section of the drawing, where in the flesh it's an adequate vent... but it has me curious about what sort of pattern of filth you're seeing outside the cones, if in fact it is on the smaller side.

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 11:17 pm

by gunny50

T-Rex wrote:Here is a picture from AACs baffle patent. (pic is too large to embed)

The angle, from the skirt back to the face, is well passed 90*

This is THE X Baffle. Have not steen Amy pictures of it

Re: 45 k baffle critique

Posted: Thu Jan 12, 2017 11:33 pm

by quietoldfart

Re: 45 k baffle critique

Posted: Fri Jan 13, 2017 7:03 am

by jarrodl

T-Rex. What is the diameter of that K? What size bore did you use?

Re: 45 k baffle critique

Posted: Fri Jan 13, 2017 7:43 am

by T-Rex

gunny50 wrote:

This is THE X Baffle. Have not steen Amy pictures of it

I could be wrong, but I believe the Ti-Rant design is based off this patent.

jarrodl wrote:T-Rex. What is the diameter of that K? What size bore did you use?

The diameter should be about 1.240. I used a 1-3/8"x.065 tube, and anodized the baffles, so the clearance should be about .003+/-.

I'm not 100% on the bore size, but I would guess a 1/2" or 13mm reamer.