Page 1 of 2

Success - K baffle 22 suppressor with photos

Posted: Fri Jun 03, 2011 8:57 pm

by Enfield577

Hi Guys

I just finished my first K baffle 22 suppressor and have to say the results are really good, you just hear a very subdued thud

I tried it on a test rig I made with a 6" barrel so I believe it would be a good test.

It is made from alloy tube with a bore of about 27/32" and an o/a length of about 7", I got 8 K baffles in there with a 3/4" spacer to form a blast chamber

Following previous advice I bored out the end cap and stacked the baffles with the 45 deg holes in line.

It threads onto the gun with the usual 1/2" thread

Now I may try some variations, maybe a monocore or some angled stainless washers Like I have seen.

I will try to post some photos later

Cheers

Re: Success - K baffle 22 suppressor

Posted: Fri Jun 03, 2011 11:16 pm

by delta9mda

dont bother with the mono-core or the slanted washers (no really).

the k is still being used for a reason and with out help you did good.

we want pics!!!

Re: Success - K baffle 22 suppressor - with photos

Posted: Sat Jun 04, 2011 2:28 pm

by Enfield577

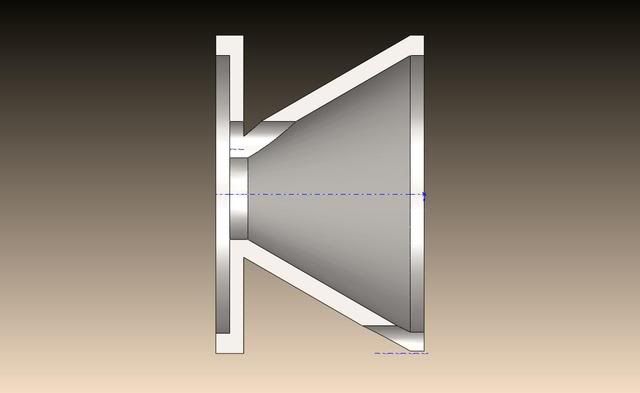

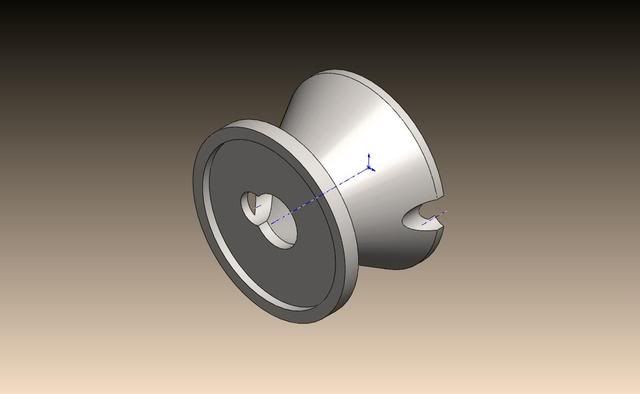

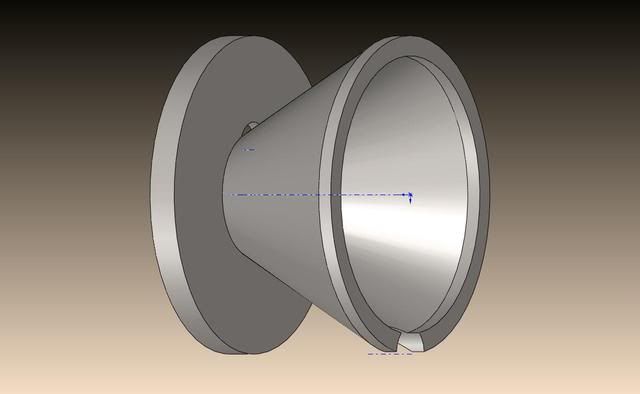

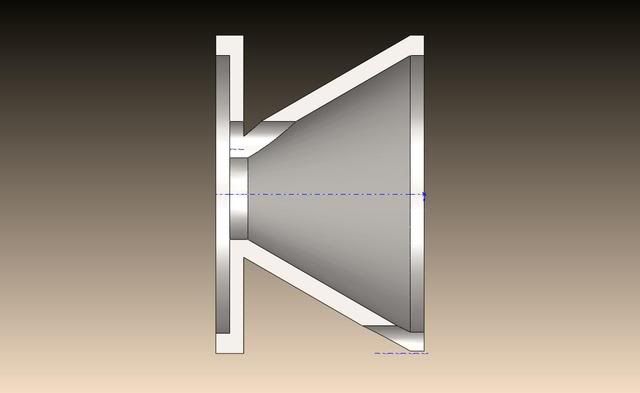

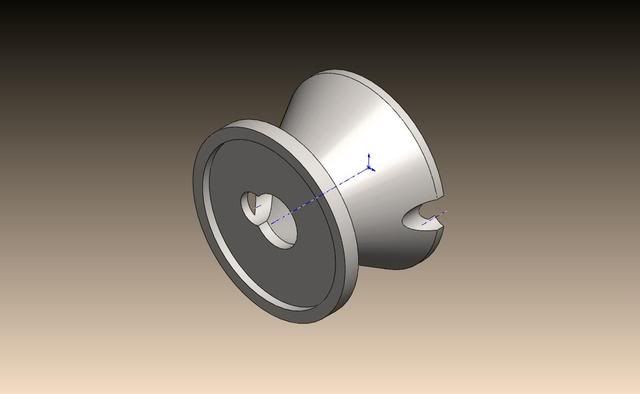

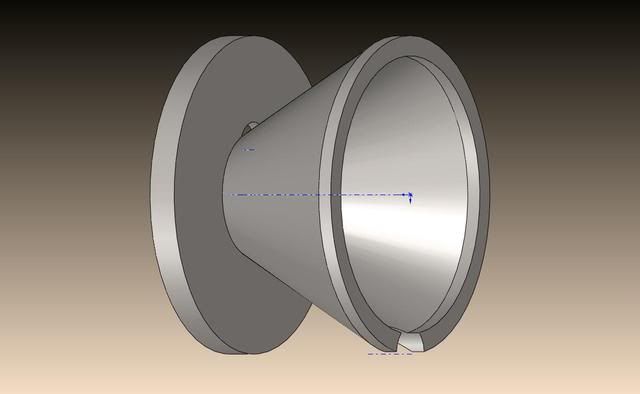

Photos as requested

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 05, 2011 10:45 pm

by zreed042

So why is there a second half hole (if it's called that) on some K baffles and not on others?

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 05, 2011 11:39 pm

by delta9mda

zreed042 wrote:So why is there a second half hole (if it's called that) on some K baffles and not on others?

ive have asked this of two manufacturers. one said he has not seen it used on any of the k baffles.

the other said that things that work are kept and things that dont are not. the second hole at the large end of the cone is what we are talking about.

in the Mick Finn patent he has a cone spacer with this feature.

im not sure how or why it does or does not work. producing mine, i will not have it there. none of the big boys are using it and we know what results they are getting.

enfield, next time do the angle of the cross bore at more like 60 degrees and not (what appears) 45. also use a slightly smaller drill. you did nothing wrong it can just be improved some, that is all.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 12:56 am

by Enfield

Got it

All the baffles that I made are the same, the cones are 60 deg and as you said the angled hole is at 45 deg, I set it up in the mill at 45 and dropped a 1/4" long series end mill down the side of the cone breaking through the centre hole and clipping a bit out of the back flat face of the baffle, so looking in the direction of the projectile you have a bore of 5/16" with a hole going off at 45deg.

So I should do this hole smaller (say 3/16") and at around 60 deg so that it does not cut into the side of the cone so much ???

You also mentioned a while ago about using a ball mill to produce this - how is it done ???

Any suggestions would be great as it is going well so far

Cheers

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 1:17 am

by Enfield577

Hey Delta

just a thought are you suggesting that I don't go right through with the cross bored hole, say just through from the outer cone shape to the projectile bore and not bother going through and forming the little cut-out in the flat back face ?

Cheers

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 7:15 am

by WhisperFan

Wow - I bet that's quiet! That is a lot of volume for a mere .22 LR suppressor!

My only suggestion is to add a shallow 'mouse-hole' opposite the side of 45 degree cone.

Like this:

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 11:18 am

by delta9mda

whisper, i disagree. that mouse hole is not used by any of the top manufacturers at all. none. not a one.

there is a reason for this. Doc Dater told me himself (they dont use the mouse hole on the tundra, MM or the outback).

aac does not use the feature either. not a one.

enfield, you want to cross all the way through but at a steeper angle so as to make the port at the cone smaller.

you want to catch the rear of the flat face too and cause a "scoop" that is correctly termed a slanted sidewall. it helps direct the gas thru the port in the cone.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 11:33 am

by CThomas

This

Not this

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 12:16 pm

by delta9mda

Ct, the reason his porting looks that way is because he drilled thru back to front or front to back.

modern aac, gem-tech etc are done in a 2 ball mill operation. one front and one back. that is why i also said he needs to do a steeper angle for the drill. take out less material from the cone.

the result is pretty much the same. Slanted Sidewall. learn it people.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 1:36 pm

by Golf_1911

delta9mda wrote:Ct, the reason his porting looks that way is because he drilled thru back to front or front to back.

modern aac, gem-tech etc are done in a 2 ball mill operation. one front and one back. that is why i also said he needs to do a steeper angle for the drill. take out less material from the cone.

the result is pretty much the same. Slanted Sidewall. learn it people.

Hi Delta,

My drawing K-Baffle will work or I have to change to drill a mouse hole at 45 degree as other?

I don't know how to draw it by solidwork.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 2:16 pm

by rcrdps

Using your first pic for orientation:

That hole ABOVE the bore should be milled from the right hand side, and should not pierce through to the left hand side. Use a ball mill to make it look like the others.

Coming from the left hand side of that pic, with a ball mill, do the same exact thing BELOW the bore.

On the left hand side, keep the area around the bore thick, so that you will have more room to do these operations and make them overlap.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 2:42 pm

by WhisperFan

delta9mda wrote:whisper, i disagree. that mouse hole is not used by any of the top manufacturers at all. none. not a one.

there is a reason for this. Doc Dater told me himself (they dont use the mouse hole on the tundra, MM or the outback).

aac does not use the feature either. not a one.

So what is the reason? I know that the Tactical Innovations isn't consdered to be a 'top maker' but they do sue it on the Tac65 (or at lease they did when I bought one.)

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 2:58 pm

by delta9mda

whisper, the actual reason (science of it) has not been explained to me but none of the big boys are doing it. take a look at the element, tirants, evo, eco, multi mounts, tundra, outbacks etc. they do not use it.

i think it has something to do with gas restriction and not trying to direct gas flow from one baffle to the next one. could be more complicated than that or simpler.

when i get the "real" answer i will let you know.

golf1911, pm me and i will send you drawings of what you need to do. basically what you have now is not correct.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 9:13 pm

by winsor

The little exit hole promotes more divert flow. I heard a better sound result with less baffle.

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 06, 2011 11:58 pm

by delta9mda

winsor wrote:

The exit hole promotes more divert flow. I heard a better sound result with less baffle.

this is good, remove the little hole in the cone. done.

Re: Success - K baffle 22 suppressor with photos

Posted: Tue Jun 07, 2011 1:37 am

by Enfield577

Excellent, thanks guys

I think I have it now so the additional ports should be cut in two operations

1, With baffle held vertical (back flat face up) sink a ball nose cutter down cutting about 1/2 the dia of the cutter, then drag to centre bore hole

2, With baffle held vertical large cone end up) sink ball nose cutter, say about the dia of the cutter, then drag to centre bore hole

It looks like the depth of cut must make the bottoms of the cuts overlap by say the radius of the cutter, in any case it looks like the gas is intended to hit the step then shoot across to the other cutout and some gas would disperse into the cavity on the outer face of the cone. I plan to use a1/4" dia ball nose cutter

Could you just confirm I have it right ?????

Cheers

Re: Success - K baffle 22 suppressor with photos

Posted: Tue Jun 07, 2011 1:45 am

by delta9mda

sounds like you understand now. good man.

when i draw it, the end of the mill is at the mid line of the thickness of the flat part (both directions).

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 12, 2011 12:59 am

by Enfield577

Well Guys intetersting results, I tried a new set of baffles as suggested, this time with the cut-outs from each end with a ball mill.

I have to say the older baffles with the hole at 45deg, cutting into the outside of the cone was about 10% quieter

So the experimentation will carry on, next time I may cut/drill the hole through at say 60 deg rather than 45 so that it does not cut into the outer face of the cone so much.

Cheers

Enfield

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 12, 2011 1:54 am

by saltydecimator

this is awesome! our little "free" friend in NZ can experiment at will un like us "free" americans!

looks a lot smoother in that second set of baffles btw. nice job!!!

what are the laws about machineguns in NZ?

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 12, 2011 3:31 am

by Enfield577

saltydecimator wrote:this is awesome! our little "free" friend in NZ can experiment at will un like us "free" americans!

looks a lot smoother in that second set of baffles btw. nice job!!!

what are the laws about machineguns in NZ?

Yes things are pretty good over here

Now the laws re machine guns etc, you have to get a collectors licence (quite easy to get if you have no bad history) then you can have just about whatever you want, however with a collectors firearm you can have the gun and it is allowed to be in working order and you have no restrictions on buying ammo but you are not allowed to fire anything that you have on a collectors licence

You must however keep it with vital part removed ie firing pin.

I have a Skorpion and understand that they go quite well, or so I am told anyway

Cheers

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 12, 2011 5:16 pm

by delta9mda

good job bro, that is what im talking about

Re: Success - K baffle 22 suppressor with photos

Posted: Sun Jun 12, 2011 7:07 pm

by Enfield577

delta9mda wrote:good job bro, that is what im talking about

That is thanks to your help of course

Re: Success - K baffle 22 suppressor with photos

Posted: Mon Jun 13, 2011 12:47 am

by delta9mda

im not going to pick at the baffles but the only thing i would change (and this is not a big deal) is use a smaller ball mill for the port at the flat/ cone junction (so as to have a smaller port and remove less material). this may (possibly) cause an increase in suppression as it will restrict the gas flow (in my opinion). other than that you are sooooo on the right track now. i like the work you have done.

this is good. yo este, what you gotta say about this? hahaha