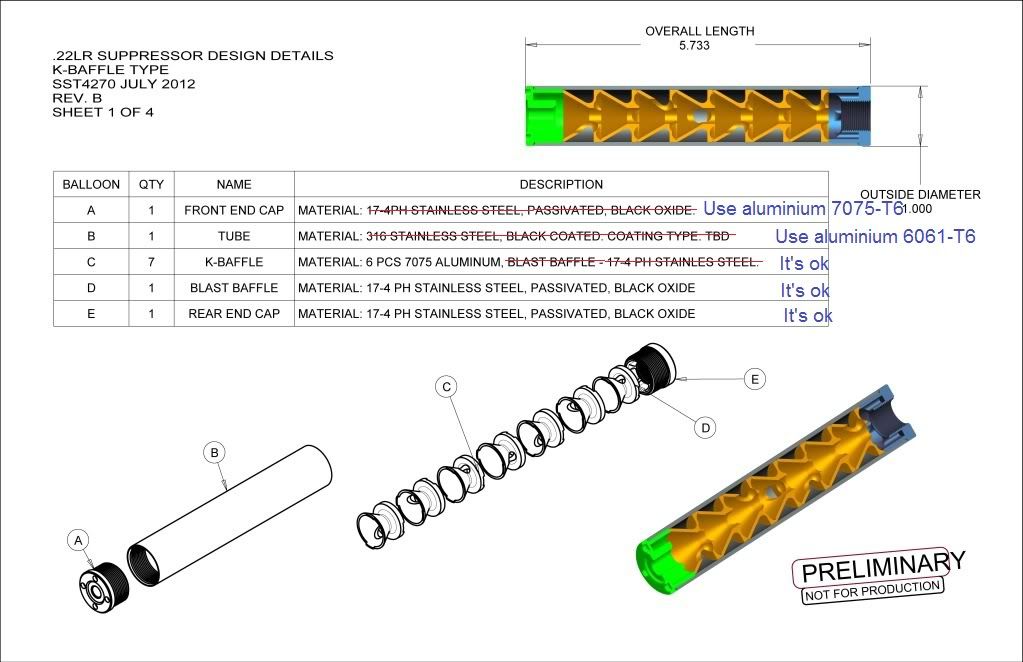

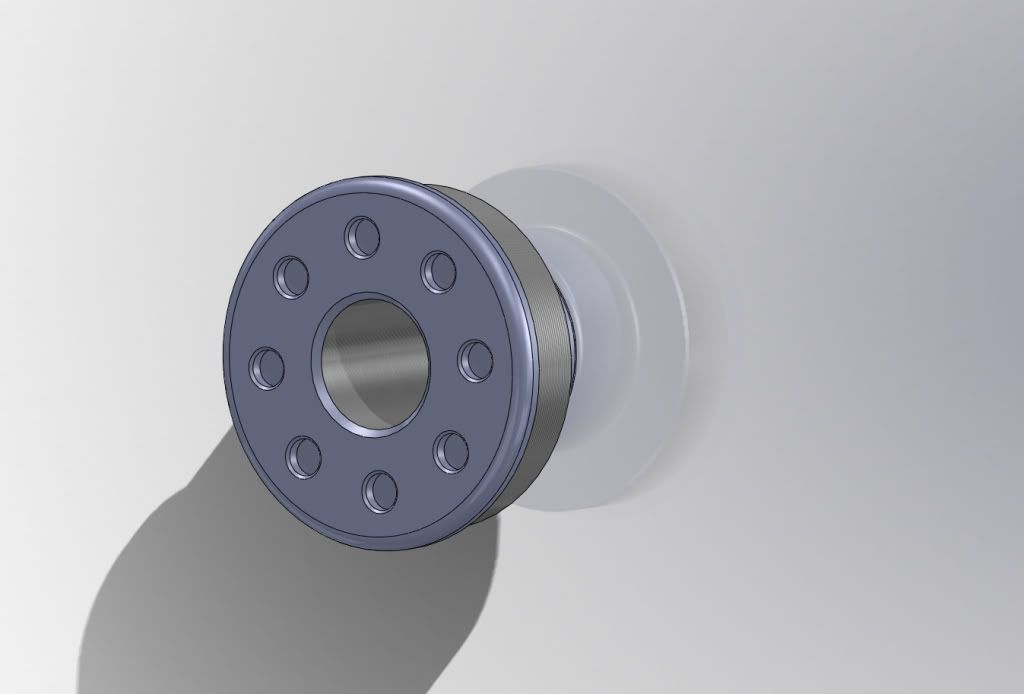

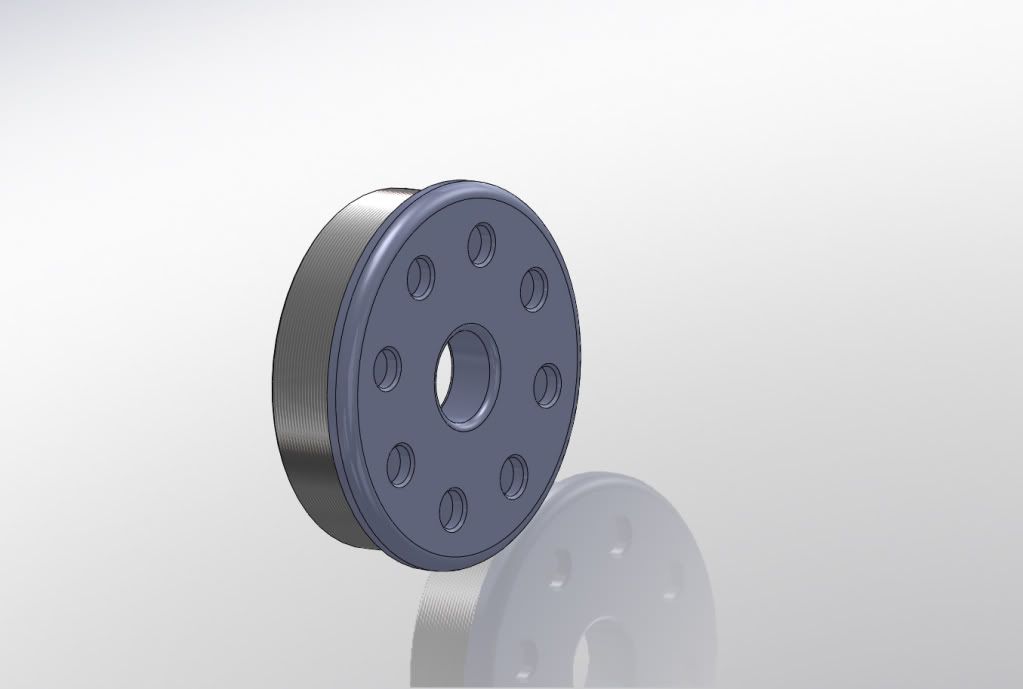

Please critique my design. It was inspired by SBR's post. Since I'm an mech engineer by profession I couldn't help but do a full 3D work up.

Awaiting Form 1 so I wanted to get as much feedback as possible prior.

Some questions I have in particular:

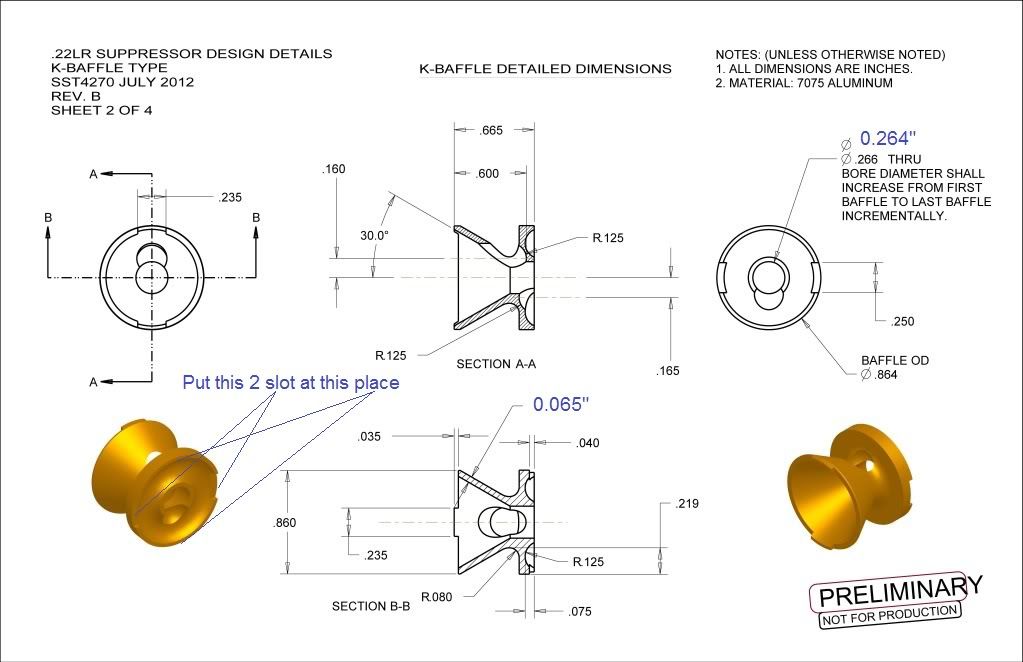

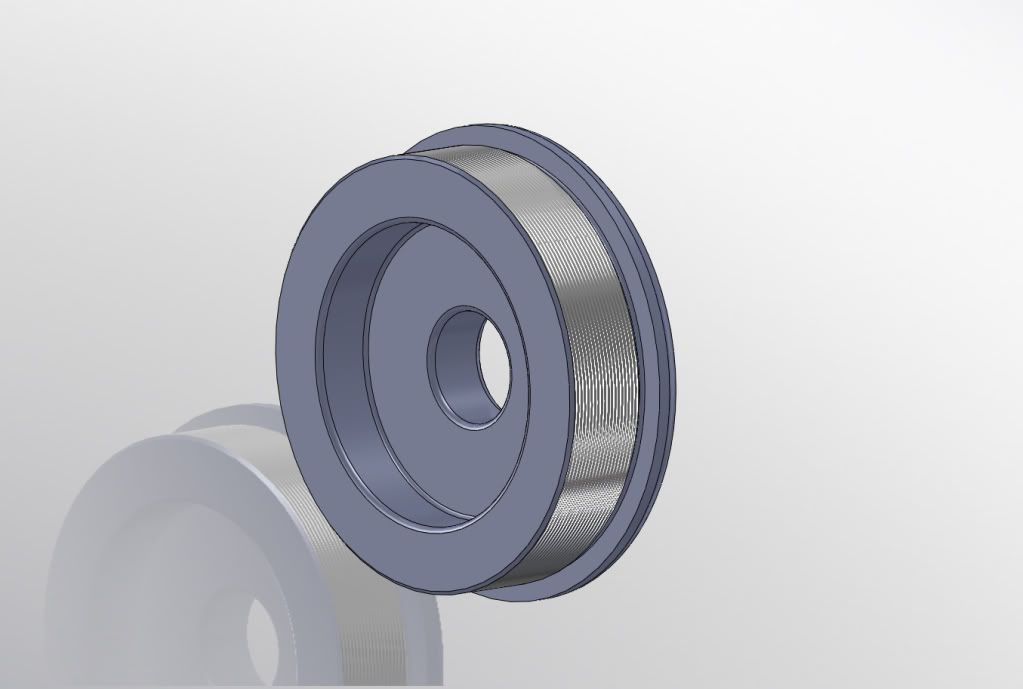

Bore size is currently @ 0.240". I think that will be too small. SEE UPDATE

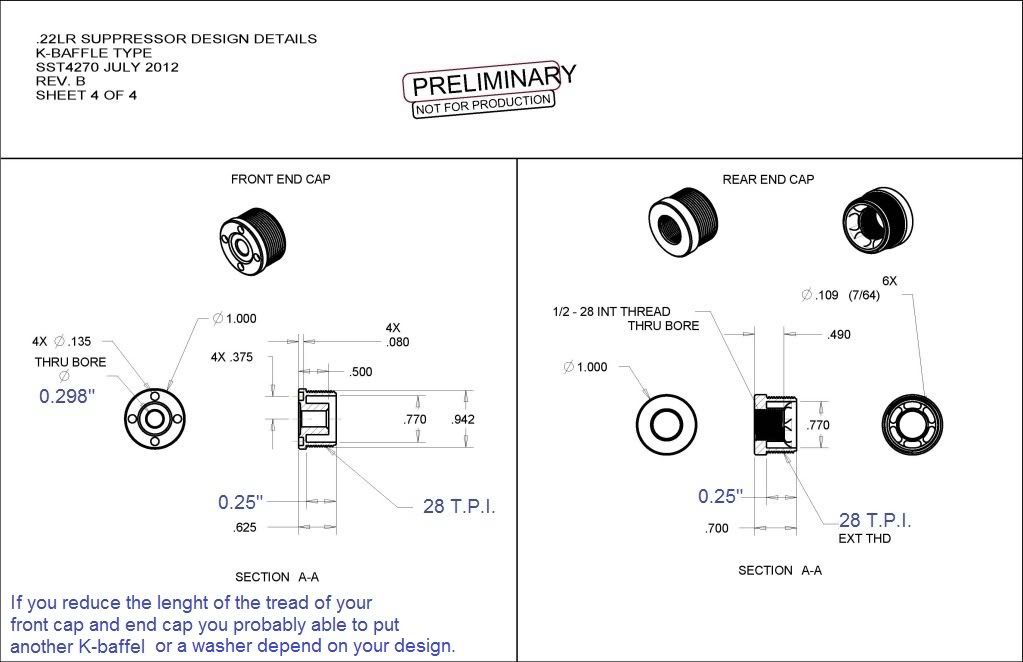

1/2" - 28 barrel thread is only 0.375" engagement. I think that is also too short. I should probably lengthen that to at least 1/2". SEE UPDATE

A couple of other things:

I noticed a couple of typos. Please don't be too harsh on those.

The K-baffles will be hard coat anodized

Calculated weight is coming in just under 8 oz.

Thanks in advance for your feedback.

Regards,

SST

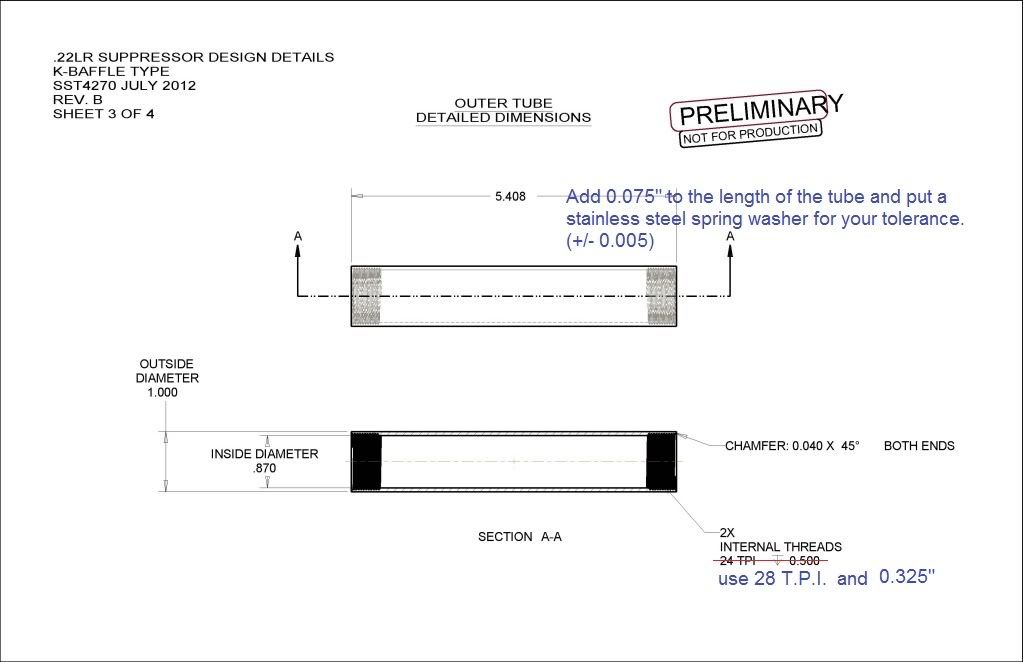

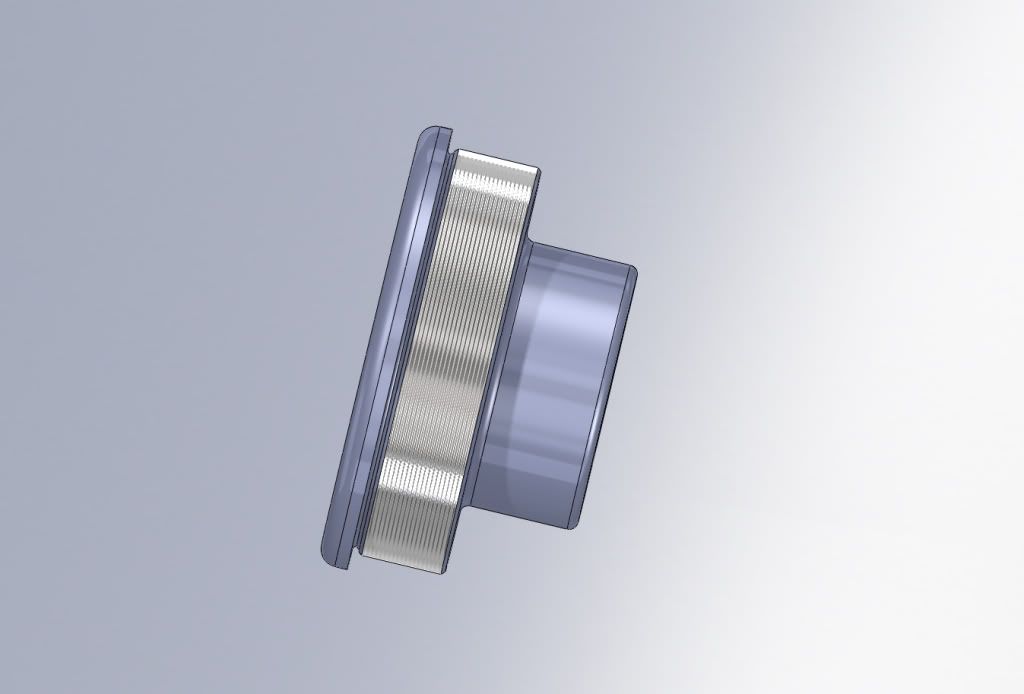

REV. B: Updated the drawings based on your feedback.

Removed spacer, added "snout" to inside of outer endcap, increased bore to 17/64 (optional: increase bore in stepped increments from baffle 1 to baffle 7)

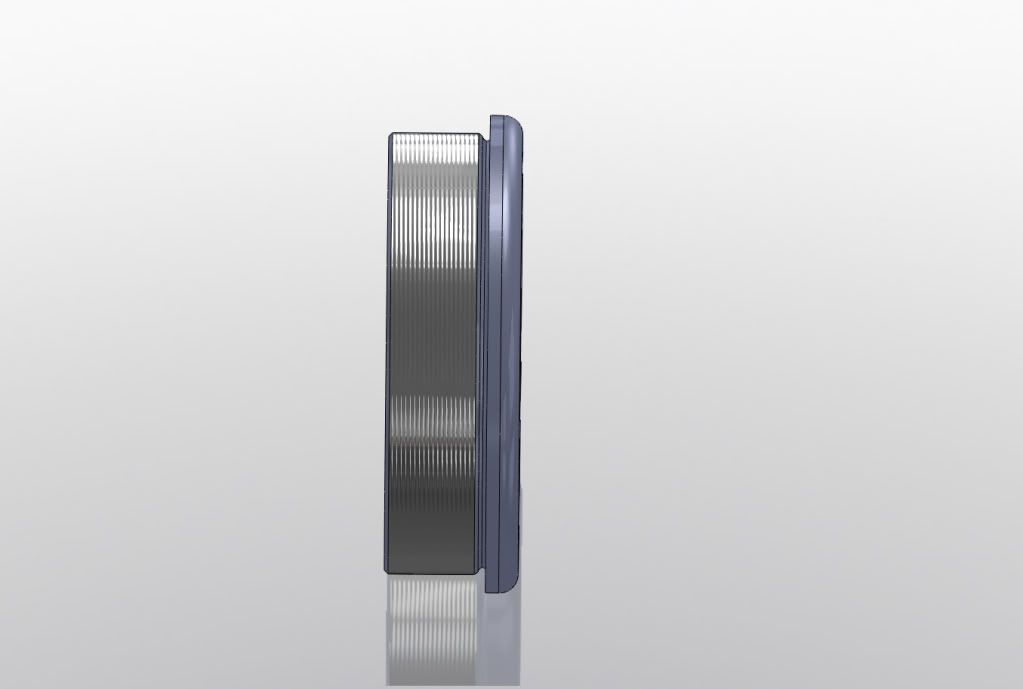

Overall length has shortened by approx. 3/8", increased length of 1/2-28 threads for more engagement onto barrel.

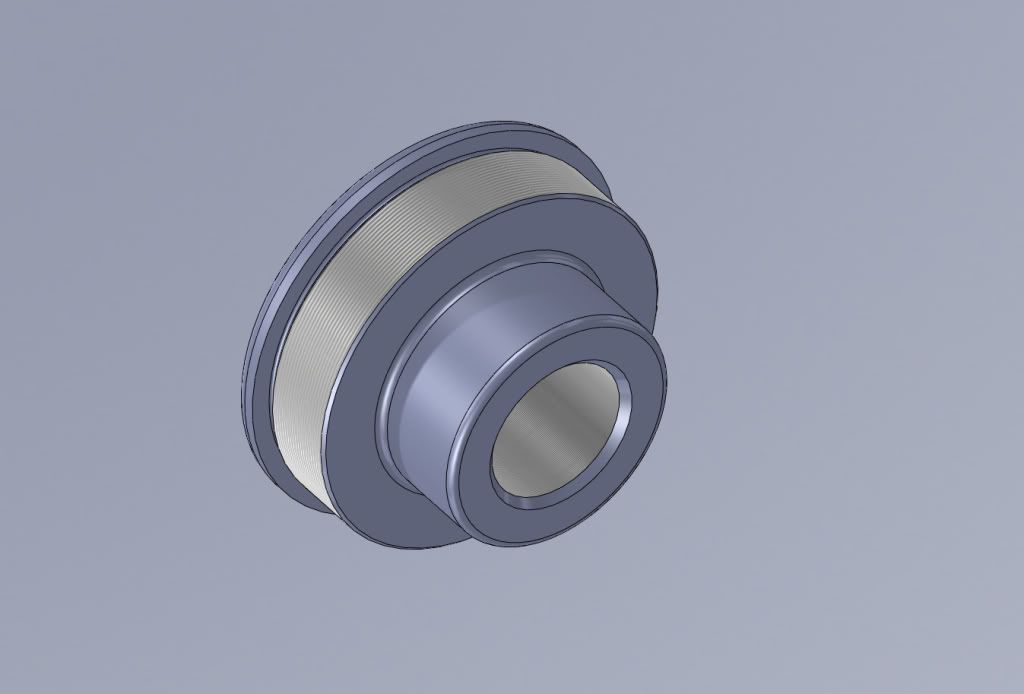

REV. C: Updated the drawings based on your feedback.

Added chamfer to snout on outer endcap directing gasses internally

Shortened last k-baffle to fit inside outer endcap - This shortened the OAL again. (This is about as short as I can go because this is being built to go onto a Tacsol SB-X barrel. If I shorten the suppressor much more I won't be able to install/remove it by hand easily.)

Added a little meat to the 'waist'.

Changed material of outer endcap to aluminum.

On another note: I notice there doesn't seem to be a common set of terms when describing the features of a K-baffle. I see various terms used for the same features causing a lot of back and forth chatter. There should be a sticky on this forum that calls out a standard set of terms for the various parts of a K-baffle. Such as: skirt, waist, rim, this hole, that hole, etc... or whatever.

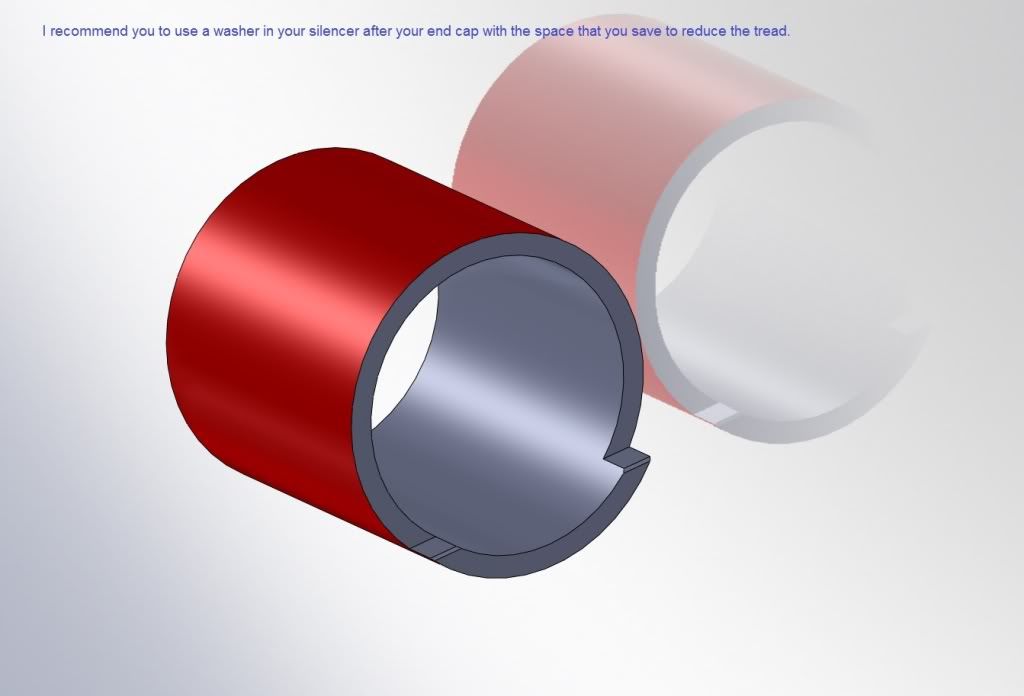

Anyways here are the latest drawings: