Has anyone tried a cone and flat baffle?

Has anyone tried a cone and flat baffle?

I was thinking about a design with a cone then a flat baffle and then a spacer. The flat baffle could be profiled similar to the face of a k baffle with a scoop and the cone could be clipped or not. Seems like with the cone it may work ok with higher velocity rounds.

AAC 7.62SD

SWR Warlock

SWR Warlock

Re: Has anyone tried a cone and flat baffle?

If the apex of the cone in protruding into the center/bull's eye of the washer for stability thenmdfoster wrote:I was thinking about a design with a cone then a flat baffle and then a spacer. The flat baffle could be profiled similar to the face of a k baffle with a scoop and the cone could be clipped or not. Seems like with the cone it may work ok with higher velocity rounds.

you have a profile of a K. The only added feature would be to make a hole in the washer

to act as sort of K-mouse_hole.

For possible variations on the theme here are interesting 'truncated olive like cones'.

<< http://www.alibaba.com/product-gs/32741 ... bases.html >>

- twodollarbill

- Silent But Deadly

- Posts: 420

- Joined: Wed May 30, 2007 5:25 pm

- Location: wisconsin

Re: Has anyone tried a cone and flat baffle?

What caliber?

If it's for a pistol caliber or rimfire, you'd be better off with K's.

I'd go with cones (clipped or not) for rifle calibers.

You could post a drawing of your complete stack.

You will get recommendations on where to tweak it.

If it's for a pistol caliber or rimfire, you'd be better off with K's.

I'd go with cones (clipped or not) for rifle calibers.

You could post a drawing of your complete stack.

You will get recommendations on where to tweak it.

Re: Has anyone tried a cone and flat baffle?

Picturing it like you described, the flat baffle would in effect 'close' the end of the cone?

What part of NC?

What part of NC?

--------------------------------------

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

Re: Has anyone tried a cone and flat baffle?

I was thinking a 0.5-0.75" gap between the flat washer and the next cone.CMV wrote:Picturing it like you described, the flat baffle would in effect 'close' the end of the cone?

What part of NC?

Raleigh

Seems like it may work better than a k-baffle for higher velocity rounds. Might be intetesting to try on a 17 hmr.

AAC 7.62SD

SWR Warlock

SWR Warlock

- Bendersquint

- Industry Professional

- Posts: 11357

- Joined: Sat Jan 07, 2006 7:19 pm

- Location: North Carolina

- Contact:

Re: Has anyone tried a cone and flat baffle?

You are pretty close to us.mdfoster wrote:I was thinking a 0.5-0.75" gap between the flat washer and the next cone.CMV wrote:Picturing it like you described, the flat baffle would in effect 'close' the end of the cone?

What part of NC?

Raleigh

Seems like it may work better than a k-baffle for higher velocity rounds. Might be intetesting to try on a 17 hmr.

Why not go with a proven design?

What caliber is the Form1 for?

Re: Has anyone tried a cone and flat baffle?

.22 and .30Bendersquint wrote:You are pretty close to us.mdfoster wrote:I was thinking a 0.5-0.75" gap between the flat washer and the next cone.CMV wrote:Picturing it like you described, the flat baffle would in effect 'close' the end of the cone?

What part of NC?

Raleigh

Seems like it may work better than a k-baffle for higher velocity rounds. Might be intetesting to try on a 17 hmr.

Why not go with a proven design?

Probably will. The idea came to me and havent seen it done before.

What caliber is the Form1 for?

AAC 7.62SD

SWR Warlock

SWR Warlock

Re: Has anyone tried a cone and flat baffle?

Posting for OP

--------------------------------------

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

"Sorry but you cannot use search at this time. Please try again in a few minutes"

"This board is currently disabled"

These things make me

-

Wildcatter

- Member

- Posts: 31

- Joined: Sat Nov 03, 2012 11:29 pm

Re: Has anyone tried a cone and flat baffle?

Have any of the 07 folks on this forum tried this?

A bunch of us have built cans with cones and spacers for high powered rifles on form 1s because it's easy and it works. The reason multiple cones work so well is because you have so many opportunities for high velocity, high pressure gases to be peeled off of the bore centerline before the projectile uncorks. In low pressure, large bore applications(458 socom subs or pistol rounds) you typically need more surface area, like with K baffles, to cool the gasses before uncorking. This design looks likes it gives both within a finite space. An added feature is the rigidity that spacers provide between the cones. I have heard stories about K baffles collapsing in higher pressure applications if they are not reinforced with thicker sidewalls. This design looks like it gives the baffle surface area of the K with some of the off-axis space of a stacked cone structure and opportunities for dater holes, mouse holes and cone structures to be added to redirect gases above and beyond Ks or cones. Anyway, I'm not saying this is the end all, be all in baffle design. I think I will try it on my pending form1 build and report results. My stamp should be here next week.

---Catter

A bunch of us have built cans with cones and spacers for high powered rifles on form 1s because it's easy and it works. The reason multiple cones work so well is because you have so many opportunities for high velocity, high pressure gases to be peeled off of the bore centerline before the projectile uncorks. In low pressure, large bore applications(458 socom subs or pistol rounds) you typically need more surface area, like with K baffles, to cool the gasses before uncorking. This design looks likes it gives both within a finite space. An added feature is the rigidity that spacers provide between the cones. I have heard stories about K baffles collapsing in higher pressure applications if they are not reinforced with thicker sidewalls. This design looks like it gives the baffle surface area of the K with some of the off-axis space of a stacked cone structure and opportunities for dater holes, mouse holes and cone structures to be added to redirect gases above and beyond Ks or cones. Anyway, I'm not saying this is the end all, be all in baffle design. I think I will try it on my pending form1 build and report results. My stamp should be here next week.

---Catter

- Bendersquint

- Industry Professional

- Posts: 11357

- Joined: Sat Jan 07, 2006 7:19 pm

- Location: North Carolina

- Contact:

Re: Has anyone tried a cone and flat baffle?

We tried something pretty close to this design and for big bore applications it was not as effective as using either K's or cones. Not to mention it was alot heavier than when using just K's or cones.Wildcatter wrote:Have any of the 07 folks on this forum tried this?

A bunch of us have built cans with cones and spacers for high powered rifles on form 1s because it's easy and it works. The reason multiple cones work so well is because you have so many opportunities for high velocity, high pressure gases to be peeled off of the bore centerline before the projectile uncorks. In low pressure, large bore applications(458 socom subs or pistol rounds) you typically need more surface area, like with K baffles, to cool the gasses before uncorking. This design looks likes it gives both within a finite space. An added feature is the rigidity that spacers provide between the cones. I have heard stories about K baffles collapsing in higher pressure applications if they are not reinforced with thicker sidewalls. This design looks like it gives the baffle surface area of the K with some of the off-axis space of a stacked cone structure and opportunities for dater holes, mouse holes and cone structures to be added to redirect gases above and beyond Ks or cones. Anyway, I'm not saying this is the end all, be all in baffle design. I think I will try it on my pending form1 build and report results. My stamp should be here next week.

---Catter

Back to the drawing board, won't be revisiting that design anytime soon.

- whiterussian1974

- Silent But Deadly

- Posts: 2857

- Joined: Sat Sep 28, 2013 11:37 pm

- Location: On 8th line of eye chart.

Re: Has anyone tried a cone and flat baffle?

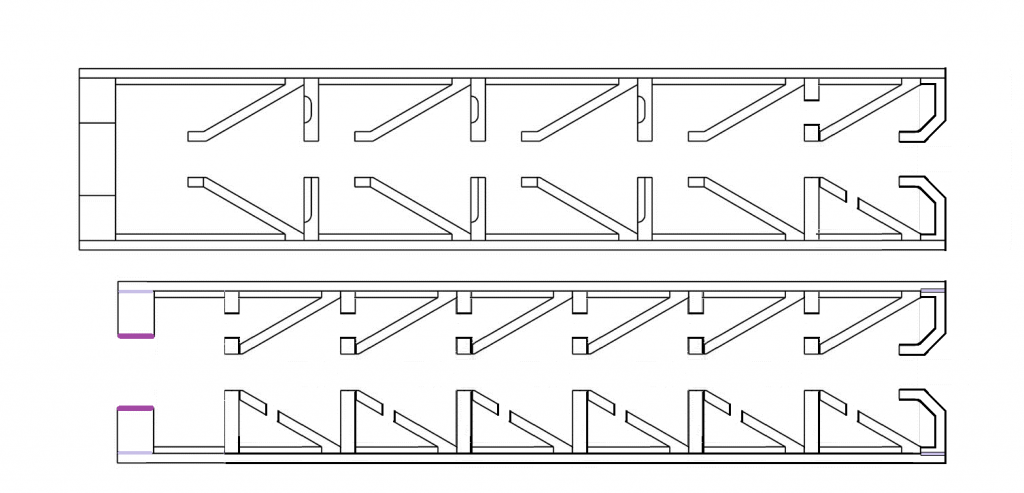

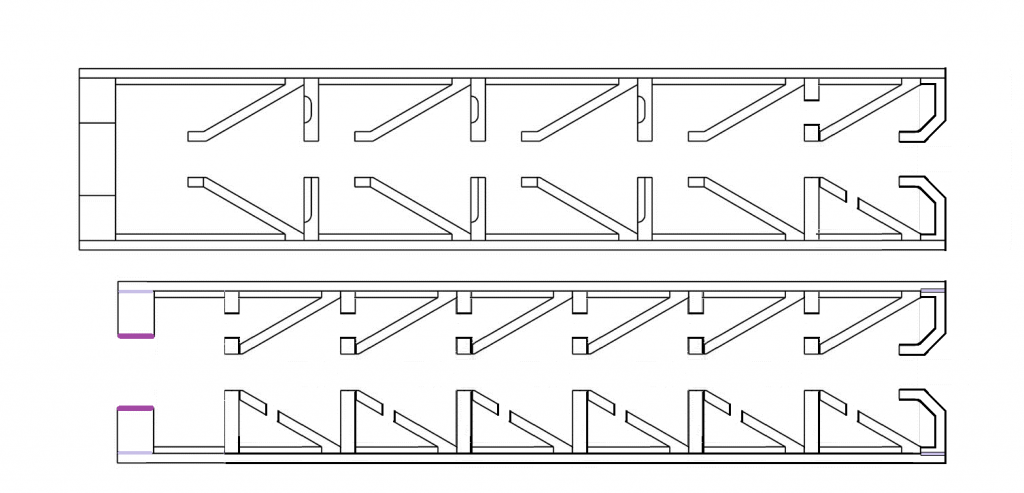

I fooled around w your idea in MS Paint for a while.

In the end I came up with a simplified version the design you described, and another member was kind enough to draw. I removed any machining from the flats, added a nozzle to your endcap to retain a gas pocket, and added Purple Lines to signify threaded areas.

It shortened the can and added an extra set of flat and cone washers. Only the endcaps need to be lathed. The rest can be sourced to fit and then drilled for porting.

Just another opinion to help visualize the project and simplify work.

The Top pic is my playing around w CMV's design. You get an idea what was rolling around in my head. The 2nd pic is what I finally arrived at.

The Top pic is my playing around w CMV's design. You get an idea what was rolling around in my head. The 2nd pic is what I finally arrived at.

Hope it stimulates some more thought.

In the end I came up with a simplified version the design you described, and another member was kind enough to draw. I removed any machining from the flats, added a nozzle to your endcap to retain a gas pocket, and added Purple Lines to signify threaded areas.

It shortened the can and added an extra set of flat and cone washers. Only the endcaps need to be lathed. The rest can be sourced to fit and then drilled for porting.

Just another opinion to help visualize the project and simplify work.

The Top pic is my playing around w CMV's design. You get an idea what was rolling around in my head. The 2nd pic is what I finally arrived at.

The Top pic is my playing around w CMV's design. You get an idea what was rolling around in my head. The 2nd pic is what I finally arrived at.Hope it stimulates some more thought.

The Darkest Corners of Hell are reserved for those who remain Neutral!-Dante

The Death of One is a Tragedy, a million only a statistic.-Stalin

silencertalk.com/forum/viewtopic.php?f=10&t=135314

The Death of One is a Tragedy, a million only a statistic.-Stalin

silencertalk.com/forum/viewtopic.php?f=10&t=135314