Tube thickness

Tube thickness

Will .065 316 SS tube be thick enough for 24 tpi threaded endcaps? This will be 1.5 tubing for a 7.62 build.

- Bendersquint

- Industry Professional

- Posts: 11357

- Joined: Sat Jan 07, 2006 7:19 pm

- Location: North Carolina

- Contact:

Re: Tube thickness

You cold go to 20tpi if you wanted as well.

Re: Tube thickness

Which would be better? I believe 20 TPI is what they are using on the Maglite conversions but the tube thickness is listed as .100 on the ones sold online. This is why I was concerned if there was going to be enough thickness on the .065 tubes since it seemed that most of the builds that use .065 are welding their end caps.

- Bendersquint

- Industry Professional

- Posts: 11357

- Joined: Sat Jan 07, 2006 7:19 pm

- Location: North Carolina

- Contact:

Re: Tube thickness

What does the Machinery handbook say the depth of the threads on a 24 and 20 tpi thread? That will tell you if there is enough to thread those tpi's.Pdave wrote:Which would be better? I believe 20 TPI is what they are using on the Maglite conversions but the tube thickness is listed as .100 on the ones sold online. This is why I was concerned if there was going to be enough thickness on the .065 tubes since it seemed that most of the builds that use .065 are welding their end caps.

If you don't have a copy.....you should.

Re: Tube thickness

+1Bendersquint wrote:What does the Machinery handbook say the depth of the threads on a 24 and 20 tpi thread? That will tell you if there is enough to thread those tpi's.Pdave wrote:Which would be better? I believe 20 TPI is what they are using on the Maglite conversions but the tube thickness is listed as .100 on the ones sold online. This is why I was concerned if there was going to be enough thickness on the .065 tubes since it seemed that most of the builds that use .065 are welding their end caps.

If you don't have a copy.....you should.

There are many old copies in used book stores for a pittance compared to

the latest version ... the compiled tables have not changed over the years.

- T-Rex

- Silent But Deadly

- Posts: 1865

- Joined: Wed Oct 29, 2014 3:38 pm

- Location: CT - The AntiConstitution State

Re: Tube thickness

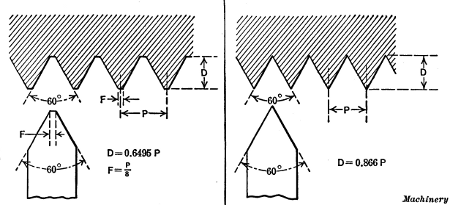

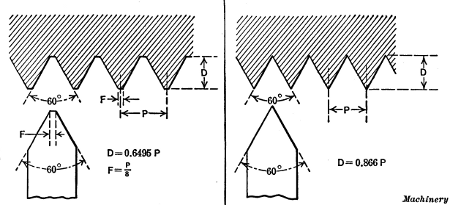

For the threads reference.

Subtract your depth of cut from the wall thickness and use your result to calculate wall strength.

Subtract your depth of cut from the wall thickness and use your result to calculate wall strength.

Completed Builds www.silencertalk.com/forum/viewtopic.php?t=79895

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Burst Calculator www.engineersedge.com/calculators/pipe_bust_calc.htm

Silencer Porn www.instagram.com/explore/tags/silencerporn/

Re: Tube thickness

Those tubes are using 1-7/16-20tpi threads, another's is using 1-7/16-24tpi threads. When it was discussed here before everyone seemed to indicate that 24 or 28tpi was the way to go, and 20tpi left it a bit thin. The 20tpi was projected to leave .027-.028" of metal at the base of the threads and 24tpi was to result in .035-036". Here is my 1.5" Tube threaded 24tpi, the calculations seemed to be accurate:Pdave wrote:Which would be better? I believe 20 TPI is what they are using on the Maglite conversions but the tube thickness is listed as .100 on the ones sold online. This is why I was concerned if there was going to be enough thickness on the .065 tubes since it seemed that most of the builds that use .065 are welding their end caps.