Recommend some carbide tools

Recommend some carbide tools

Going to attempt some titanium hacking and it looks like my HSS might not do the trick. Anything worth recommending? I'll need to thread inner and outer dimensions.

I have found a few different sets on eBay and Amazon and while not cheap, just not sure what's good.

I have found a few different sets on eBay and Amazon and while not cheap, just not sure what's good.

Re: Recommend some carbide tools

Sharp HSS works fine. See links below.

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

Re: Recommend some carbide tools

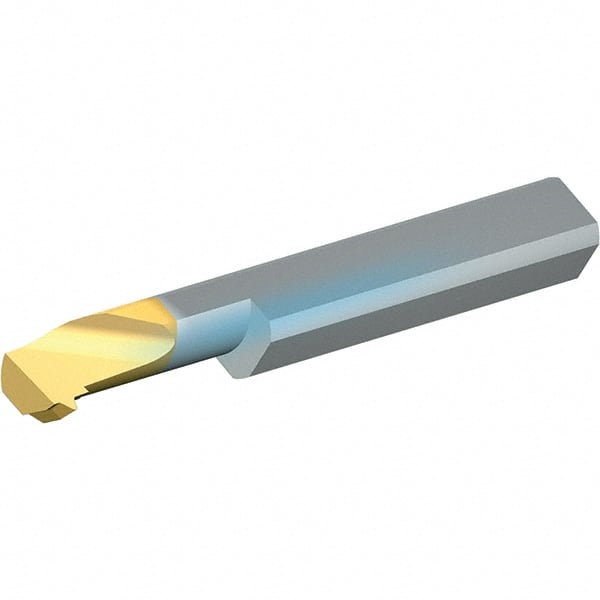

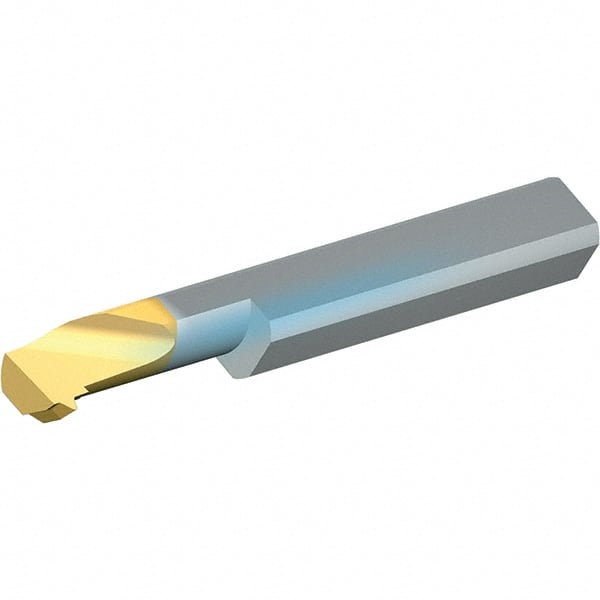

threads were cut with a solid carbide tool.

The threads are my biggest worry.

Re: Recommend some carbide tools

https://i.imgur.com/KW3kxQZ.jpg#40Fan wrote:threads were cut with a solid carbide tool.

The threads are my biggest worry.

https://i.imgur.com/4gnhgogh.jpg

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

Re: Recommend some carbide tools

An ordinary lay-down style carbide insert threading tool works fine for Ti, nothing to be concerned about there.#40Fan wrote:threads were cut with a solid carbide tool.

The threads are my biggest worry.

For the rest of the turning and boring, I really like the polished sharp carbide inserts intended for aluminum; these are razor sharp like a good HSS tool but don't loose their edge when they get hot, as Ti is prone to do when you have a lathe capable of taking deeper cuts at higher speeds. I've been getting inserts and holders from Banggood (look in their "Turning tool" section) but they are available on ebay too. IMO these are a big step forward from HSS or more traditional carbide insert geometry.

I'm not sure that little lathe Fishman uses is a good representation of tooling needs for those of us with bigger lathes, as feeds and speeds are necessarily a bit different.

-

ECCO Machine

- Silent But Deadly

- Posts: 633

- Joined: Tue Nov 28, 2017 5:34 pm

Re: Recommend some carbide tools

MMT laydown type for internal threads, NTC/NTF (Kennametal "top notch") for external.

Single point threading Ti is not particularly difficult, although you do need to be aware of deflection, especially running further into a bore with a thinner bar; you will sometimes need to feed the compound out slightly as you get deeper. This can happen with many materials, but Ti is worse for it.

Single point threading Ti is not particularly difficult, although you do need to be aware of deflection, especially running further into a bore with a thinner bar; you will sometimes need to feed the compound out slightly as you get deeper. This can happen with many materials, but Ti is worse for it.

FFL07/02SOT Gunsmith & Machinist

Re: Recommend some carbide tools

Thanks. I think I clicked on your 300 BLK thread and found the line I quoted. For some reason your links in your signature are not active now, so I can't confirm which one it was. Too lazy to copy and paste.fishman wrote:https://i.imgur.com/KW3kxQZ.jpg#40Fan wrote:threads were cut with a solid carbide tool.

The threads are my biggest worry.

https://i.imgur.com/4gnhgogh.jpg

Everyone else, thanks for the input. I'll do some more looking before making a decision. I'm not in a hurry so maybe I'll wait for the Ti to show up and give it a try with the HSS before spending any money.

Re: Recommend some carbide tools

Dont let your tool get too hot. Like yondering said, once a HSS tool gets too hot and loses its edge, forget it. If you cant touch the tools because they're too hot, either slow down or use coolant between passes. Carbide is more forgiving with heat. Ive never had a tool get too hot from threading.

Drilling Ti is a bitch. Get cobalt bits. Keep them sharp. Keep them cool.

Nothing wrong with carbide, its great for titanium, but the point I was making is that it ABSOLUTELY isnt necessary.

Drilling Ti is a bitch. Get cobalt bits. Keep them sharp. Keep them cool.

Nothing wrong with carbide, its great for titanium, but the point I was making is that it ABSOLUTELY isnt necessary.

I take lighter than usual cuts when threading and I've never had this problem.Single point threading Ti is not particularly difficult, although you do need to be aware of deflection, especially running further into a bore with a thinner bar; you will sometimes need to feed the compound out slightly as you get deeper. This can happen with many materials, but Ti is worse for it.

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Recommend some carbide tools

I agree w/ the fishman.fishman wrote:Dont let your tool get too hot. Like yondering said, once a HSS tool gets too hot and loses its edge, forget it. If you cant touch the tools because they're too hot, either slow down or use coolant between passes. Carbide is more forgiving with heat. Ive never had a tool get too hot from threading.

Drilling Ti is a bitch. Get cobalt bits. Keep them sharp. Keep them cool.

Nothing wrong with carbide, its great for titanium, but the point I was making is that it ABSOLUTELY isnt necessary.

If you can grind a toolbit why buy carbide. Use a high cobalt HSS like T-15.It will cut anything and is so inexpensive.

-CL

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

-

ECCO Machine

- Silent But Deadly

- Posts: 633

- Joined: Tue Nov 28, 2017 5:34 pm

Re: Recommend some carbide tools

What thread pitches, diameters, thread class and depths have you done? 20 or 24 pitch class 2B 1/2" long with a 3/4" bar is a whole different animal than threading an inch deep or more, 32, 36, 40 pitch 3B with a 3/8" bar.fishman wrote:I take lighter than usual cuts when threading and I've never had this problem.

Courser pitches and looser thread classes, you'd never notice it without a thread mic. Defelction is much more apparent when cutting fine pitches with tight thread class.

FFL07/02SOT Gunsmith & Machinist

Re: Recommend some carbide tools

20-28tpi and up to about 0.8" deep

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

Re: Recommend some carbide tools

Is this correct?fishman wrote:20-28tpi and up to about 0.8" deep

At 65% fit one adds to diameter: at 28TPI it should be around .0285".

20 TPI ... .0422"

Most likely I am reading the above incorrectly.

-

partsguy22

- Senior Silent Operator

- Posts: 144

- Joined: Thu Feb 12, 2015 2:24 pm

- Location: N. Texas

Re: Recommend some carbide tools

I'm sure he ment hole depth not thread depth

- Capt. Link.

- Silent But Deadly

- Posts: 2829

- Joined: Wed Oct 17, 2007 9:05 pm

- Location: USA.

Re: Recommend some carbide tools

These work well for internal threading on small machines. Works well in standard tool posts or QC type. HSS available.

https://www.mscdirect.com/browse/tn/Thr ... d=12105974

Accupro 1 Inch Cutting Depth, 14 to 40 ... ce $45.61

Vargus Specs Single Point Threading Tools; Th ... carrier.

-CL

https://www.mscdirect.com/browse/tn/Thr ... d=12105974

Accupro 1 Inch Cutting Depth, 14 to 40 ... ce $45.61

Vargus Specs Single Point Threading Tools; Th ... carrier.

-CL

The only reason after 243 years the government now wants to disarm you is they intend to do something you would shoot them for!

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=79895

Re: Recommend some carbide tools

I very strongly recommend against both of those for one simple reason. When doing internal threading, its way easier to use a left hand tool and thread in reverse. That way, you cant crash the machine, ruin your tool, or ruin your part if you overshoot.

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

-

ECCO Machine

- Silent But Deadly

- Posts: 633

- Joined: Tue Nov 28, 2017 5:34 pm

Re: Recommend some carbide tools

That's personal preference. I hate threading away, only do it to cut LH threads with RH tooling. I routinely thread into .050" undercuts, internal or external, @ 350 RPM doing 20-40 pitch on a 17" swing lathe with 3" of half nut lever throw no problem. I'll often slow it down to 160 for courser pitches.fishman wrote:I very strongly recommend against both of those for one simple reason. When doing internal threading, its way easier to use a left hand tool and thread in reverse. That way, you cant crash the machine, ruin your tool, or ruin your part if you overshoot.

That would also explain why you're not noticing cutter deflection, as your internal thread taper is smaller at the front of the bore.

FFL07/02SOT Gunsmith & Machinist

Re: Recommend some carbide tools

why?I hate threading away,

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

-

Lille.DeVrille

- New Member

- Posts: 4

- Joined: Fri Dec 21, 2018 12:46 pm

Re: Recommend some carbide tools

Not recommending tools and techniques that are standard world wide is rather strange. Are you being a individualist or encouraging poor form ?fishman wrote:I very strongly recommend against both of those for one simple reason. When doing internal threading, its way easier to use a left hand tool and thread in reverse. That way, you cant crash the machine, ruin your tool, or ruin your part if you overshoot.

Re: Recommend some carbide tools

Please enlighten us peons as to why threading in reverse is poor form. I'm certainly not being an individualist. I didn't invent the concept. https://www.practicalmachinist.com/vb/g ... se-212521/Lille.DeVrille wrote:Not recommending tools and techniques that are standard world wide is rather strange. Are you being a individualist or encouraging poor form ?fishman wrote:I very strongly recommend against both of those for one simple reason. When doing internal threading, its way easier to use a left hand tool and thread in reverse. That way, you cant crash the machine, ruin your tool, or ruin your part if you overshoot.

Its rather absurd to imply that the standard way of doing things is always the best way. If there's some fatal flaw with this practice, let us know so that I can stop sucessfully threading parts this way.

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

-

Lille.DeVrille

- New Member

- Posts: 4

- Joined: Fri Dec 21, 2018 12:46 pm

Re: Recommend some carbide tools

I never had any illusion you invented the practice as its much older than anyone alive. Threading towards the tailstock is putting a huge strain on it and the spindle but I'm positive you did not think of that either.

Please self identify what type of peon you are:

*peon (pēˈŏnˌ, pēˈən)

n.

An unskilled laborer or farm worker of Latin America or the southwest United States.

n.

Such a worker bound in servitude to a landlord creditor.

n.

A menial worker; a drudge.

Please self identify what type of peon you are:

*peon (pēˈŏnˌ, pēˈən)

n.

An unskilled laborer or farm worker of Latin America or the southwest United States.

n.

Such a worker bound in servitude to a landlord creditor.

n.

A menial worker; a drudge.

Re: Recommend some carbide tools

/thread

I got my answers and we can quit this stuff.

I got my answers and we can quit this stuff.

-

Lille.DeVrille

- New Member

- Posts: 4

- Joined: Fri Dec 21, 2018 12:46 pm

Re: Recommend some carbide tools

Are you fishmans keeper ?#40Fan wrote:/thread

I got my answers and we can quit this stuff.

Re: Recommend some carbide tools

care to elaborate, or provide a source of this information? I would genuinely enjoy a technical discussion on the topic.Threading towards the tailstock is putting a huge strain on it and the spindle

If its just going to be slinging insults at me and #40fan then you're going to be ignored.

300 blackout form 1: http://www.silencertalk.com/forum/viewtopic.php?f=10&t=137293

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647

5.56 form 1:

http://www.silencertalk.com/forum/viewtopic.php?f=10&t=141800&p=955647#p955647