Page 1 of 2

full titanium 30 cal build in progress.

Posted: Tue Nov 17, 2015 12:20 pm

by Samson104

my latest form 1 is a 30 cal can that will be running on my "work gun" 308 and probably by 308 deer rifle

outer tube specs are going to be 8.5" long , 1.550" ID , .052"wall. (made from grade 5 bar)

all end caps will be grade 5 , press fit then welded in place Rear cap/brake/spacer will be documented later.

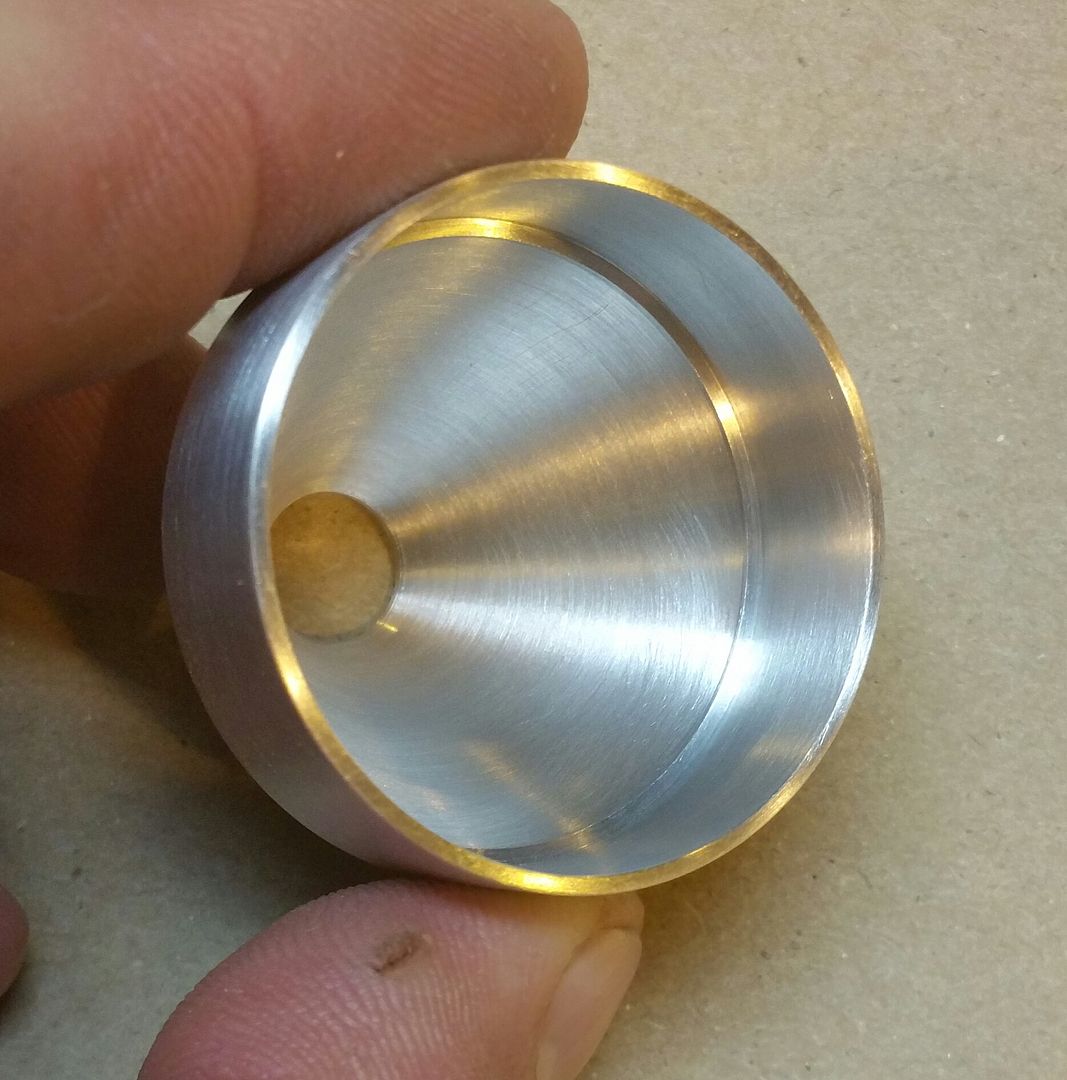

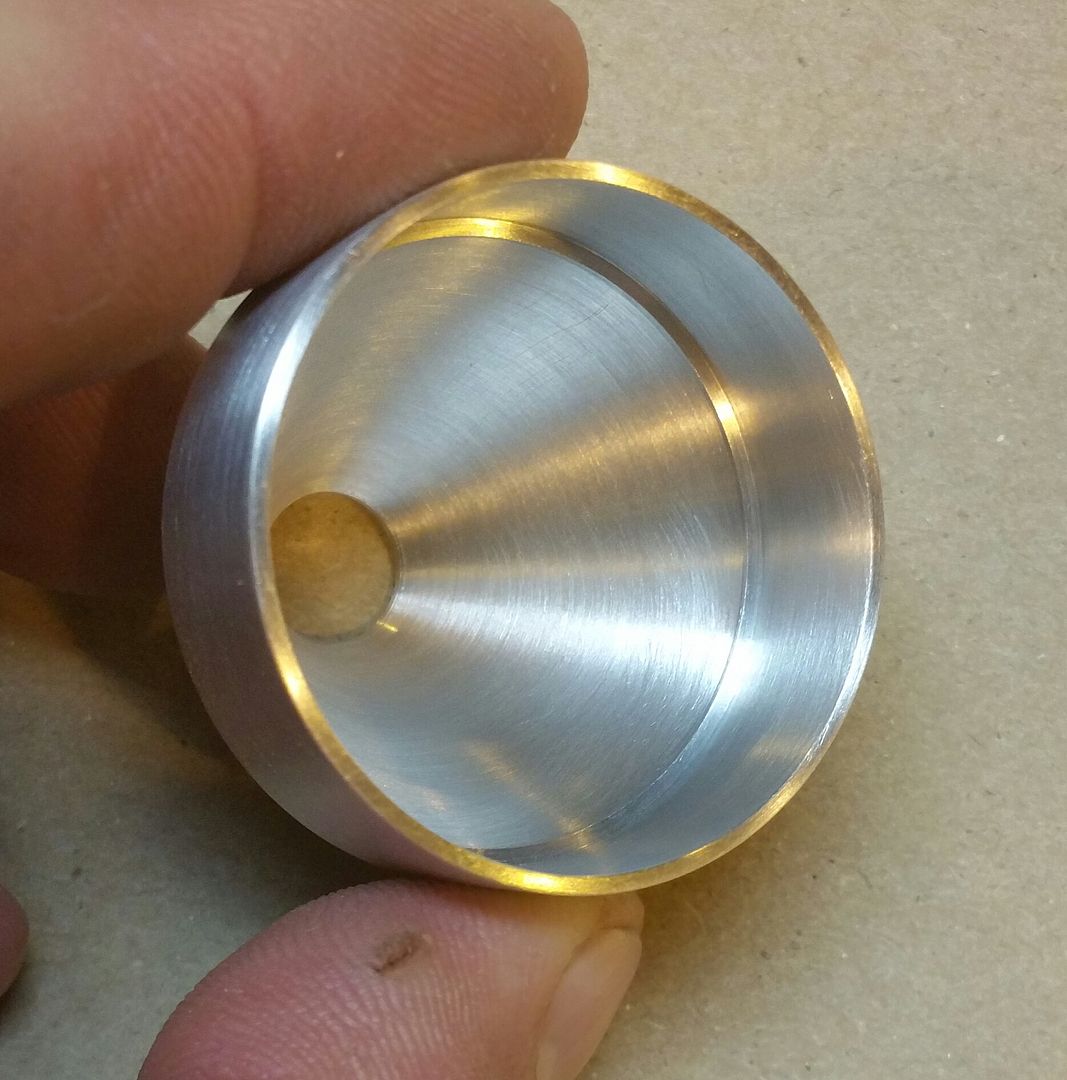

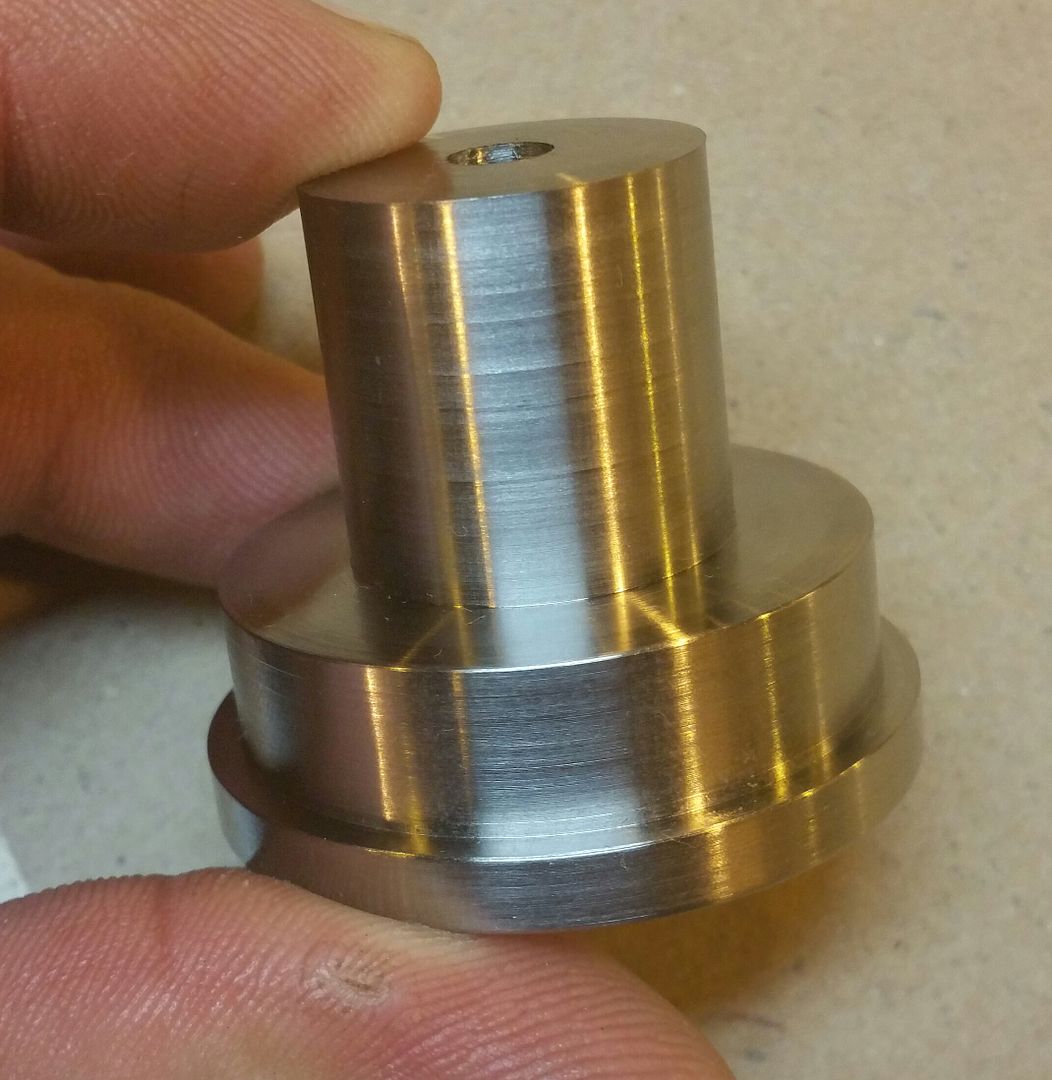

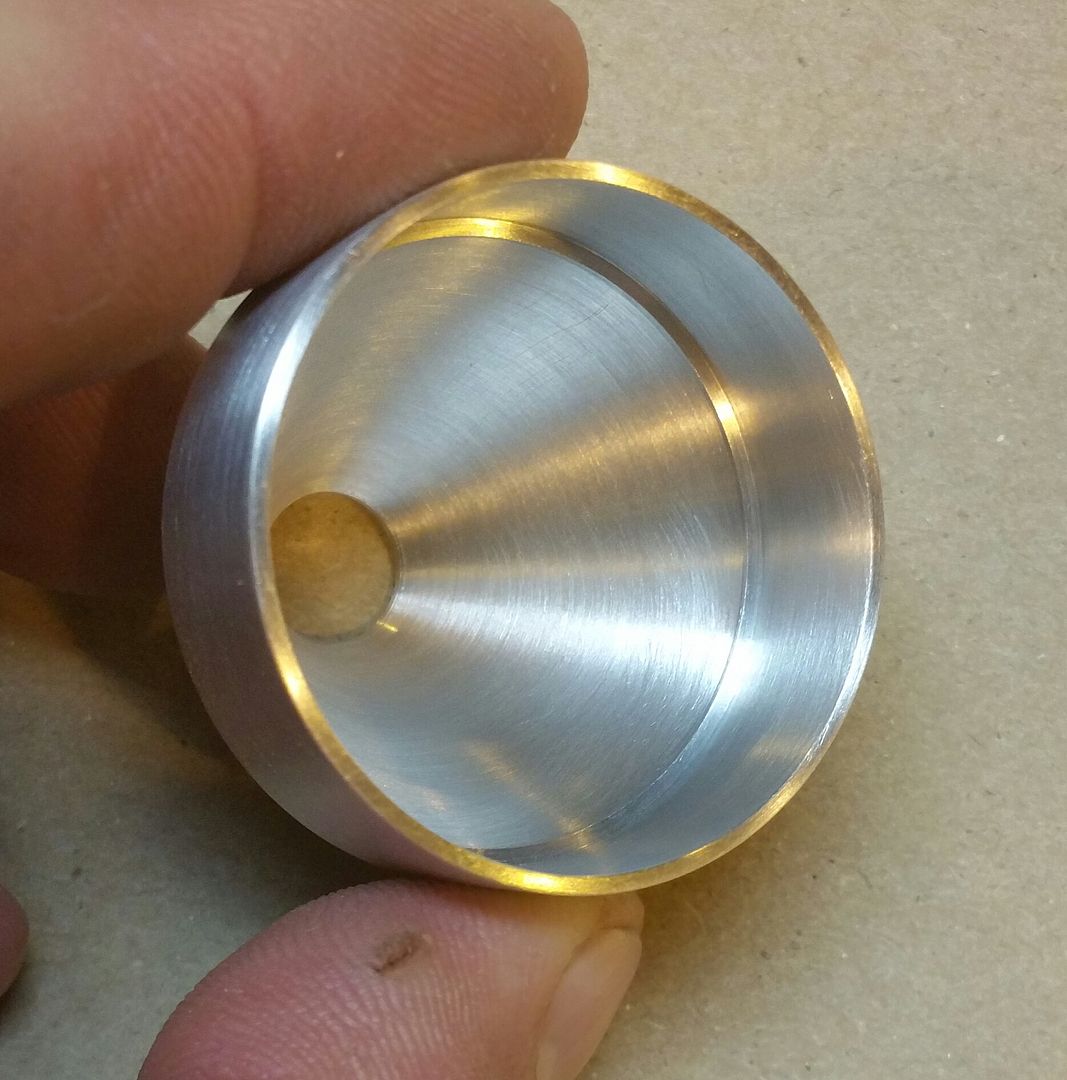

cones are grade 5 , .050" wall on the cone and .030" wall on the skirt the baffles will stack together like leggos and are spaced .500" and will have 11 cones total.

here is what the cones look like , I scuffed it come with scotch bright so it would show up better.

I'm hoping to come in lighter and function better than a buddies TBAC 30p-1

Re: full titanium 30 cal build in progress.

Posted: Tue Nov 17, 2015 7:06 pm

by delta9mda

look and learn people lol

Re: full titanium 30 cal build in progress.

Posted: Tue Nov 17, 2015 7:31 pm

by plodder

Samson104: I'd be interested to know your plans for a blast chamber, or are you just going from muzzle to Ti baffles?

Re: full titanium 30 cal build in progress.

Posted: Tue Nov 17, 2015 8:59 pm

by cal50

Clip it......

Re: full titanium 30 cal build in progress.

Posted: Tue Nov 17, 2015 11:55 pm

by L1A1Rocker

bookmarked

Re: full titanium 30 cal build in progress.

Posted: Wed Nov 18, 2015 7:44 am

by JohnnyO

Nice

Re: full titanium 30 cal build in progress.

Posted: Wed Nov 18, 2015 8:37 am

by Capt. Link.

You can always tell the machinist from the scars and wounds on his hands and body.No need for pictures or this thread may end up like a scene from the movie Jaw's comparing scars.

Nice clean work as normal from you sir!

-CL

Re: full titanium 30 cal build in progress.

Posted: Wed Nov 18, 2015 9:32 pm

by cal50

I detect some anodizing voltage variation..........

Re: full titanium 30 cal build in progress.

Posted: Thu Nov 19, 2015 12:09 am

by yondering

That's cool.

I like that endcap. Have you used that design before, and have any feedback? Mind if I copy it?

Re: full titanium 30 cal build in progress.

Posted: Thu Nov 19, 2015 6:15 pm

by delta9mda

I'm pretty sure samson is not asking for advice up in here

Re: full titanium 30 cal build in progress.

Posted: Sat Nov 28, 2015 10:12 am

by Samson104

Re: full titanium 30 cal build in progress.

Posted: Sat Nov 28, 2015 4:17 pm

by propeine

Slick integration as always samson. No 1 piece blast chamber this time?

Re: full titanium 30 cal build in progress.

Posted: Sat Nov 28, 2015 4:59 pm

by Samson104

no not this time , just going to run the tube thicker up to the first baffle.

Re: full titanium 30 cal build in progress.

Posted: Mon Nov 30, 2015 7:01 am

by Samson104

decided to clip the cones to help aid in performance , I've heard mixed reviews about hos this can or will have an impact on accuracy.

the outer tube is significantly thicker right now for the welding process , it will be turned down after both caps are fully welded out.

this is a fusion/root weld , no filler wire was used only the tube and cap material , the filler and cap passes will use 3/32 filler wire.

I ended up running this pass a bit hotter than the next two just to make sure I get good solid deep penetration and fusion , hence the dark color of the weld.

my welding cabinet is a small sand blasting cabinet that I have plumbed a good purge line and the tig torch into. after the cabinet has been purged for a while I stick the purge hose into the end of the tube to it helps with the cooling some.

Re: full titanium 30 cal build in progress.

Posted: Thu Dec 10, 2015 3:12 pm

by delta9mda

bump for ti goodness

Re: full titanium 30 cal build in progress.

Posted: Fri Dec 11, 2015 1:17 pm

by Nikwho

Thank you for posting your work, Samson! I am in the process of designing a .308 can and your build is a great reference for ideas and inspiration! I have been torn between using ti tubing w/ threaded end caps or SS tubing with a welded front end cap and threaded rear for disassembly. I may just need to stop being scared and use the sandblasting cabinet similar to how you are? May I ask what you are purging your cabinet with? Argon? (That may be a dumb question! I have not looked into welding ti). I would assume that if welding a single (or maybe two) form one can(s) is the only time I'd ever weld titanium, it is probably not worth while to get set up to weld it. Not to mention material used during the learning process of welding titanium. I am intrigued by the ti welding process. Does the inert gas that you are using have a specific gravity heavier or lighter than air, or, in other words; do you allow the air to escape the cabinet from the top or bottom? Or do you just keep it flowing during your welding and allow it to escape anywhere it chooses, with most blasting cabinets not being totally air tight? Sorry for all of the questions! Perhaps I should be posting this as a question in its own thread!

Anyhow, great looking work and thank you for sharing it!

Nik

Re: full titanium 30 cal build in progress.

Posted: Fri Dec 11, 2015 1:56 pm

by 1rosta

Does the type of clipping shape matter on the cone? Most I have seen are U shaped and the one above is more squared.

Re: full titanium 30 cal build in progress.

Posted: Fri Dec 11, 2015 6:34 pm

by cal50

A cabinet purged with argon would be a great thing to have but as long as you can shield the heated titanium until it cools below 700F you can run a large gas lens and back purdge. As long as oxygen / nitrogen is kept shielded away from the hot titanium your welds should be fine. Argon gas keeps these away from your weld.

I back purged my titanium tube by putting a hose flowing argon into the tube with a small opening on the other end so the argon can flow freely. Titanium welds up nicely.

Re: full titanium 30 cal build in progress.

Posted: Fri Dec 11, 2015 9:13 pm

by propeine

cal50 wrote:A cabinet purged with argon would be a great thing to have but as long as you can shield the heated titanium until it cools below 700F you can run a large gas lens and back purdge. As long as oxygen / nitrogen is kept shielded away from the hot titanium your welds should be fine. Argon gas keeps these away from your weld.

I back purged my titanium tube by putting a hose flowing argon into the tube with a small opening on the other end so the argon can flow freely. Titanium welds up nicely.

I'd like to give welding it a go but the damn tig rod is ridiculously expensive. I'm plenty sure of being capable just too cheap to buy filler metal. Nice looking work there!

Re: full titanium 30 cal build in progress.

Posted: Fri Dec 11, 2015 9:47 pm

by cal50

propeine wrote:cal50 wrote:

I'd like to give welding it a go but the damn tig rod is ridiculously expensive. I'm plenty sure of being capable just too cheap to buy filler metal. Nice looking work there!

You can find some cheap on fleabay or buy grade 5 filler rod by the piece around $3. To me titanium welds like other alloys but requires a good shield.

Re: full titanium 30 cal build in progress.

Posted: Fri Dec 11, 2015 11:29 pm

by yondering

cal50 wrote:

I back purged my titanium tube by putting a hose flowing argon into the tube with a small opening on the other end so the argon can flow freely. Titanium welds up nicely.

Cal, how did you set that up - did you tap in to the same line as the torch, or use a separate tank setup?

Re: full titanium 30 cal build in progress.

Posted: Sun Dec 13, 2015 4:05 am

by cal50

yondering wrote:cal50 wrote:

I back purged my titanium tube by putting a hose flowing argon into the tube with a small opening on the other end so the argon can flow freely. Titanium welds up nicely.

Cal, how did you set that up - did you tap in to the same line as the torch, or use a separate tank setup?

You can do it anyway you want as long as you have argon gas flow.

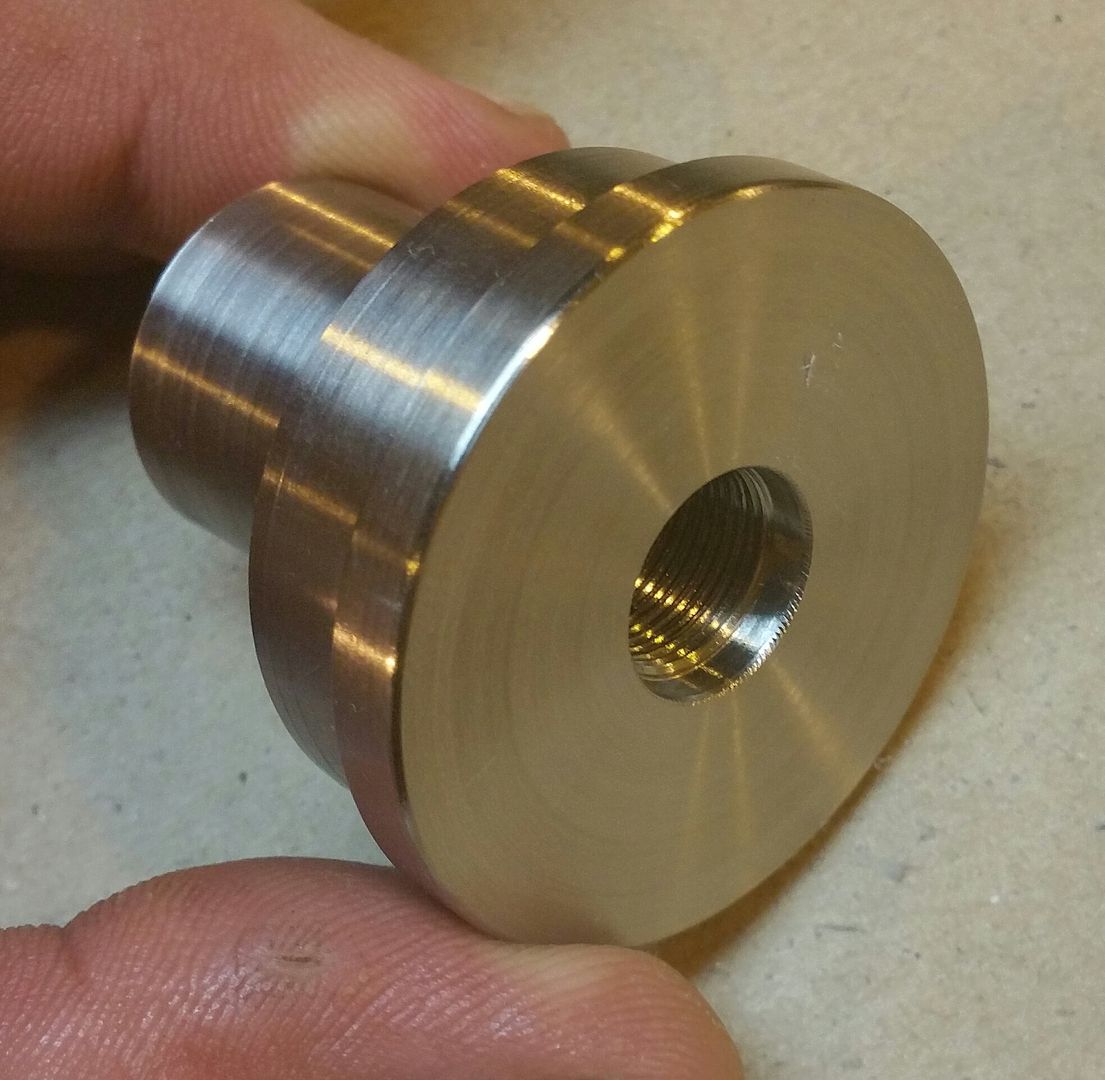

I made a brass manifold and added a separate regulator and flow valve.

Re: full titanium 30 cal build in progress.

Posted: Sun Dec 13, 2015 6:47 pm

by yondering

Thanks, the pic of that manifold helps. I'm not set up to back-purge yet, but that looks like a convenient way to do it.

Re: full titanium 30 cal build in progress.

Posted: Sun Dec 13, 2015 6:54 pm

by cal50

yondering wrote:Thanks, the pic of that manifold helps. I'm not set up to back-purge yet, but that looks like a convenient way to do it.

Its just a piece of brass with a drilled hole thru and some 1/4 NPT pipe threaded holed to fit the regulator to.

I made a barbed fitting for some hose I attached to it and adjusted the flow valve to have a small but steady flow of argon flowing thru the tube while welding.

I already had the regulator but you could do the same by putting a "Y" adapter in the argon gas line.

I did not want to take the chance of dropping the flow rate to my torch so I just plumbed in a separate regulator.

Re: full titanium 30 cal build in progress.

Posted: Wed Dec 16, 2015 5:53 am

by noisecatcher

Have you made it to the range yet?