Page 1 of 1

Design change to Form 1 end cap, thoughts?

Posted: Tue Dec 01, 2015 11:23 pm

by L1A1Rocker

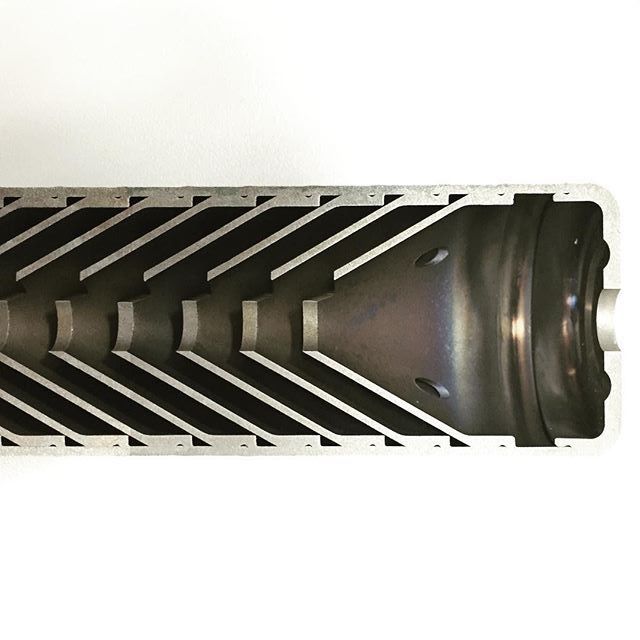

I'm looking at reducing weight on my Form 1 30 caliber can (mostly 300blk sub sonic). The tube is Gr 9 Titanium and the endcaps are Grade 5. This is the current design on the end caps - really just looking at the rear design.

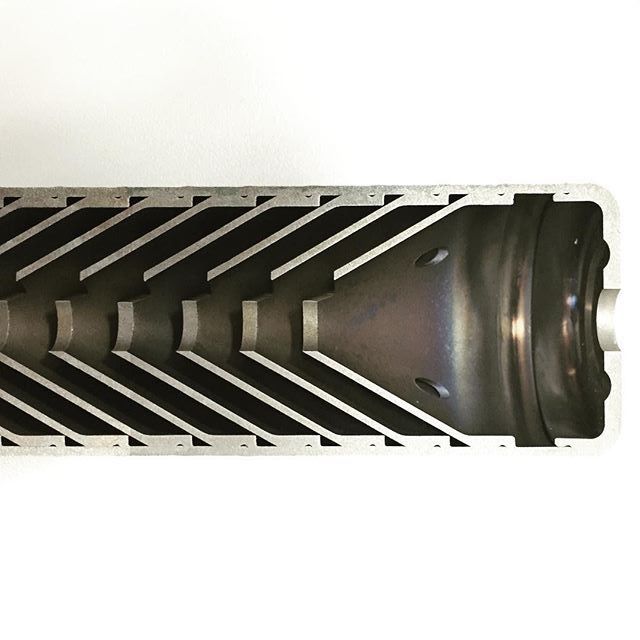

Now that rear end cap has a lot of extra metal in it that I think I can get rid of. After doing some thinking this is what I changed it to.

I moved where the tube screws on and slimmed it down a lot. The part highlighted in blue is .100" thick. I've got two questions. First, is that a sufficient thickness? And two, I'm thinking it could save me between 1 to 2 ounces. What do ya'll think I can expect to drop by going with that change?

Thanks folks.

Re: Design change to Form 1 end cap, thoughts?

Posted: Wed Dec 02, 2015 4:39 am

by gunny50

"L1A1Rocker"

The lower solution is how I did my Minimi silencers. it is also the solution that SIG is using in their cans.

Your top solution might be more stable to manufacture, all depending machines you have.

In the top model you could drill holes from the front into the thick part in the rear and make it lighter, would not be as light as the bottom one but there is room for improvement.

With a good mill and deviding head you could mill 4 banana shape slots in there.

Check my links below for the right post with sectioned silencers.

Gunny

Re: Design change to Form 1 end cap, thoughts?

Posted: Thu Dec 03, 2015 8:32 am

by L1A1Rocker

gunny50 wrote:"L1A1Rocker"

The lower solution is how I did my Minimi silencers. it is also the solution that SIG is using in their cans.

Your top solution might be more stable to manufacture, all depending machines you have.

In the top model you could drill holes from the front into the thick part in the rear and make it lighter, would not be as light as the bottom one but there is room for improvement.

With a good mill and deviding head you could mill 4 banana shape slots in there.

Check my links below for the right post with sectioned silencers.

Gunny

Thanks for your response Gunny! Do you think .100 thickness is sufficient? Oh, and I didn't see any pics of your "Minimi" silencers. Did I just miss them?

Re: Design change to Form 1 end cap, thoughts?

Posted: Thu Dec 03, 2015 9:10 am

by gunny50

L1A1Rocker wrote:gunny50 wrote:"L1A1Rocker"

The lower solution is how I did my Minimi silencers. it is also the solution that SIG is using in their cans.

Your top solution might be more stable to manufacture, all depending machines you have.

In the top model you could drill holes from the front into the thick part in the rear and make it lighter, would not be as light as the bottom one but there is room for improvement.

With a good mill and deviding head you could mill 4 banana shape slots in there.

Check my links below for the right post with sectioned silencers.

Gunny

Thanks for your response Gunny! Do you think .100 thickness is sufficient? Oh, and I didn't see any pics of your "Minimi" silencers. Did I just miss them?

My minimi silencer is not in those posts.

Wall 3,5mm 4mm over thread should be just fine for 300 BLK if you also use 308 or more I would go 4,5mm, that is probably what SIG is using as well.

The threaded portion with SIG is in front so more body there in their design. Also thread after the shoulder keeps your thread from fouling.

Print sectioned model, do some calculations.

be safe

Gunny