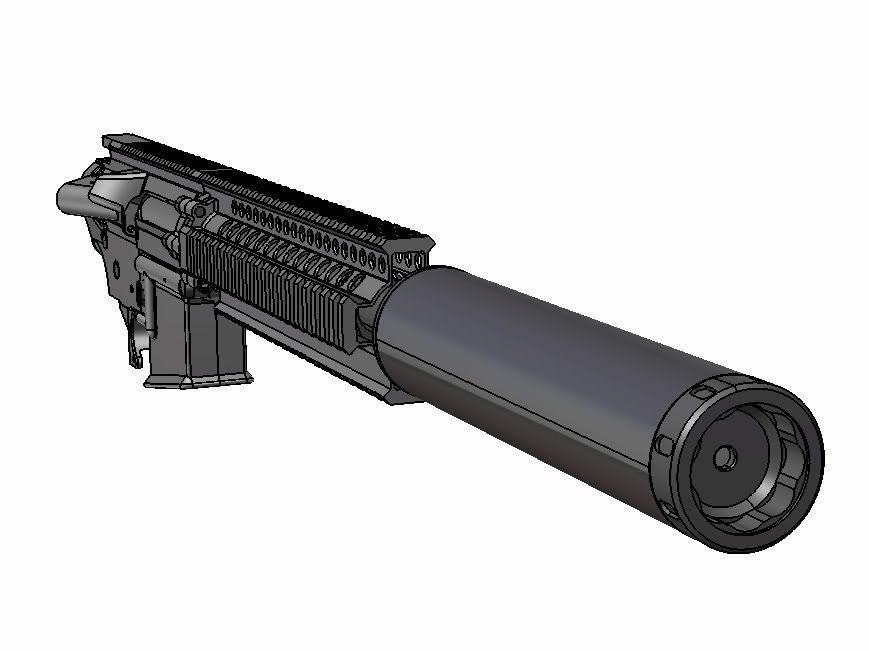

About 2 years ago I learned about NFA items, and more specifically, the legality of a DIY suppressor. Last year I started designing a can that I could use on my AR. I tried to establish some guidelines for my design.

Here was my priority list:

1. Maximum internal volume

2. Minimal weight

3. Max lifetime

4. Max number of baffles

5. Max ease of manufacture

DESIGN

I don't shoot very often, and sometimes my cleaning habits are sloppy (oops), so #3 was a biggy. Because I'm fairly confident in my own machining ability I was able to put "manufacture" last on the list, with the stipulation that there not be any welding involved. I can TIG but don't do it regularly and don't trust myself enough to put a valuable body part like an eye on the line. My outer boundary ended up being about 1-7/8" OD, and 9.5" long. On a 10.5" barrel this would put the OAL length around 20". Anything larger than this I considered unacceptable. From that point I considered a variety of baffle designs. Because I mainly do CNC mill work and don't have access to that nice of a lathe, I determined fairly early on that I wanted a monolithic core. All of the parts besides the core would use a design that would minimize the number of turning operations.

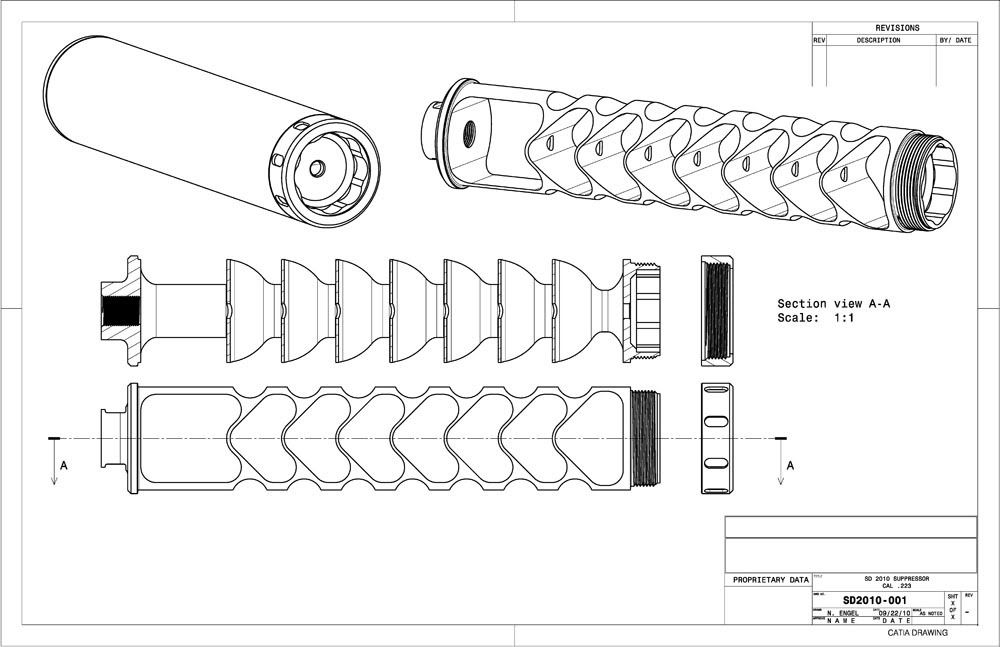

I went through four or five baffle styles, ranging from more traditional milled offset bores, AAC Prodigy style angled/etc/etc. At that point I decided that I wanted symmetric baffles around at least 1 axis to least affect POI, and that's when I nailed down my final baffle shape. I realized that from a structural standpoint it was pretty sound; fairly well triangularized, not subject to excess deformation. By the time I started refining these baffles, I hadn't yet decided how to retain the outer tube. Any threaded joint I wanted to keep in pure shear, so that pretty much eliminated threading the tube itself. I also wanted something that was as far from the blast chamber as possible to reduce carbon fouling. So I sacrificed a little on the weight and location of the center of gravity, and added a retention nut to the loud(er) end.

So this is what I ended up with. The tube is sandwiched between the core at the rear and the cap up front. The tube needs to be only close on the ID, moderately straight, and faced on both ends. For now the mount end is simple, 1/2x28 threaded. The cap gets threaded 1-5/8x18 and sees only shear from preloading the tube. The core is in tension and has a shoulder so that the end cap bottoms on the core up front before it overloads either the fairly thin core legs or buckles the tube. I was very happy with myself until I realized something...To reach the proper torque (about 20 ft-lb), I would have to hold the core on the mount end with a wrench because the tube would rotate. No problem...Or was it? I discovered that when the core was torqued up from one end to the other, I was surpassing the MAXIMUM shear strength of the material in several locations that had a factor of safety of 1.5 - 2 when loaded in tension. I would likely have broken my core either the first time I put it together or the first time I took it apart. To solve this I added a crescent pattern on the ID of the core end, so I can insert a milled wrench to hold the core when I tighten the cap up.

The tube being in compression is probably not ideal. Wall thickness is .055". However, when a round is actually fired and the tube is pressurized, thanks to the Poisson effect, the tube will actually shrink along its length up to .005" or .006", which will increase the buckling strength (or pressure capability) by decreasing the amount of preload that the end cap applies on it. I wish I could say this was my intent all along, but hey, I'll take it

The end cap was my final consideration. What I ended up with is something that I can make entirely on the CNC machine. My biggest problem here was coming up with a design that could take an O-ring (in case I wanted to prevent alot of carbon from getting into the threads) and keeping the weight down. My next biggest problem was making it not look like complete crap. That probably took the most work...But I'm happy with it now.

MATERIALS

After I finalized the style and was able to determine the loads that the structure would be seeing in each area, I spent some time nailing down the materials. I will be using 321 stainless for the core. It is not heat treatable, so what I started out with would be the best AND worst material strength I was going to get. It is highly resistant to heat, corrosion, and embrittlement(see #3 on my list). The tensile strength is okay. I also have a little bit of experience making exhaust flanges out of 321SS, so that's on my side.

The tube will be made (pending availability) from 6AL-4V titanium. It can easily take the loads and keeps the weight down. The tube shouldn't see extremely high temperatures, and blasted titanium looks awesome. Enough said.

The cap...I haven't decided yet. I'm a little apprehensive about also making it out of a stainless alloy, as it could cause thread galling. On the other hand, I'm not a huge fan of rust...Leaning heavily towards titanium right now for weight and corrosion reasons.

End specs:

OAL: 9.500"

OD: 1.875"

Weight: 1lb 12oz

Internal Volume: 16.1 in^3

Baffles: 7 x "FI" baffles + 1 flat one on the end

Criticism is quite welcome as this IS my first rodeo.

Manufacturing plan coming up next!